Bottom filtration method slag treatment system and control method thereof

A technology of slag treatment and flow control, which is applied to the bottom filtration slag treatment system and its control field, can solve problems such as overflow, waste of water resources, waste of water resources, etc., and achieve the effects of prolonging service life, saving water resources and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

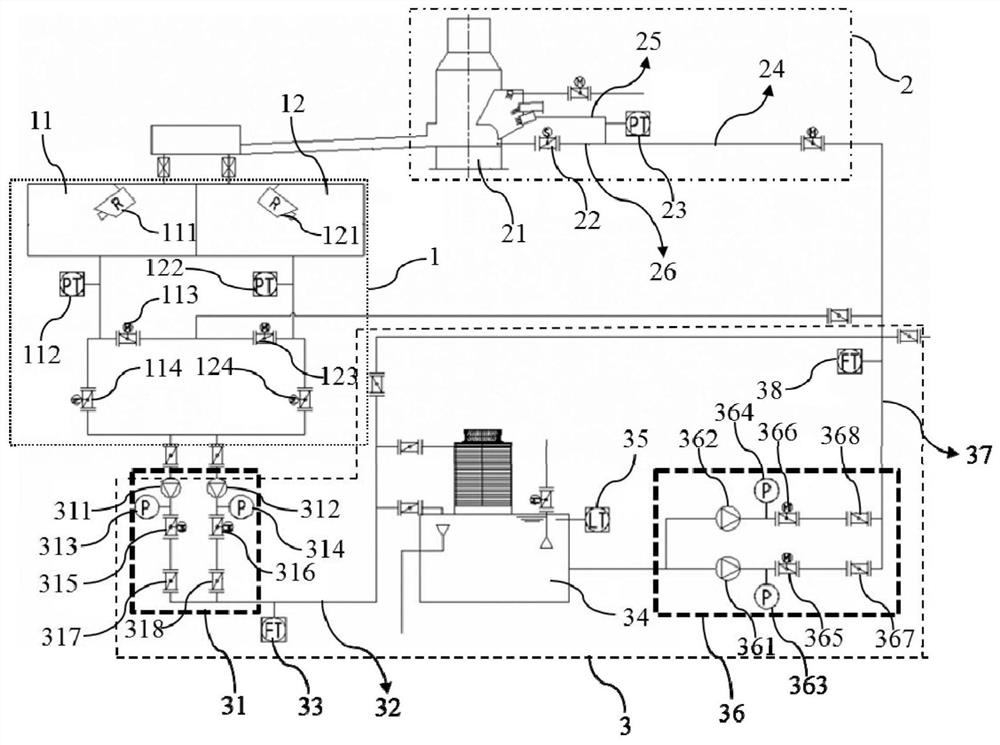

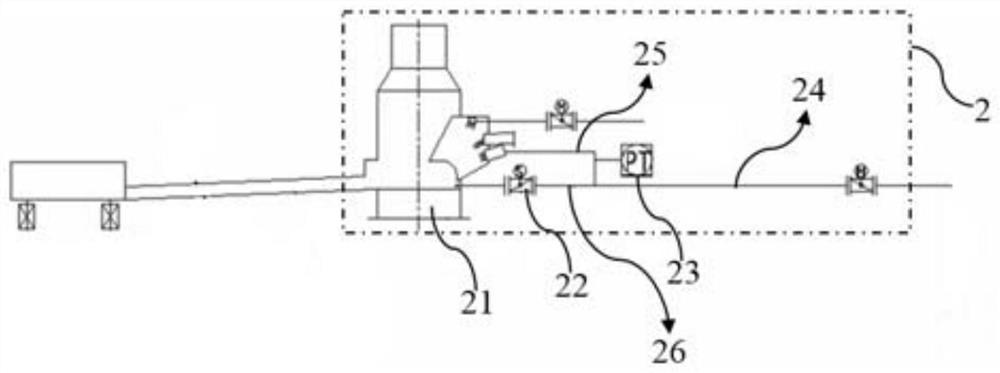

[0040] A kind of bottom filtration method slag processing system of the present embodiment, such as figure 1 As shown, it includes a filter tank liquid level monitoring system 1, a slag flushing water pressure control system 2, and a pipeline flow control system 3. The outlet end of the pipeline flow control system 3 connects with the slag flushing water pressure control system 2 The slag flushing water pressure control system 2 discharges slag water into the filter tank liquid level monitoring system 1 through the granulation tower 21, and the outlet end of the filter tank liquid level monitoring system 1 passes through the pipe and the pipeline The inlet ends of the flow control system 3 are connected to realize the control of the liquid level of the filter tank, the control of the slag flushing water pressure and the control of the water balance, thereby prolonging the service life of the water pump and the filter tank, saving water resources, and making the bottom filter T...

Embodiment 2

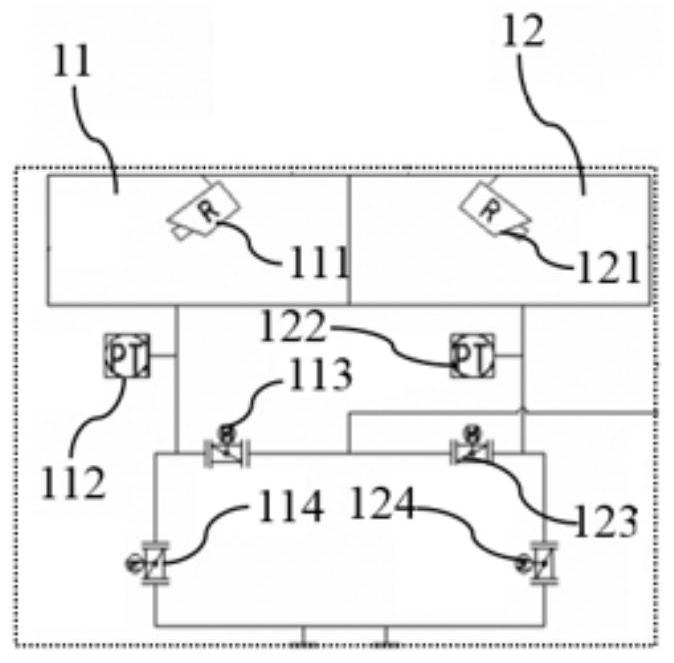

[0045] A kind of bottom filtration method slag processing system of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are: as figure 2 As shown, the slag-grabbing filter pool 12 is externally connected with a pressure transmitter ΙΙ122 through the main filter pipe, and the pressure transmitter ΙΙ122 transmits the received signal to the computer screen in the main control room, thereby converting the pressure into slag-grabbing The water level in the filter tank 12, in order to avoid the situation of grabbing slag with water because of bad control of the water level in the slag receiving filter tank 11. Such as figure 1 As shown, the slag-grabbing filter pool 12 is communicated with the pumping flow control block 31 through a pipeline, and the opening and closing are controlled by the electric valve III123 and the electric valve IV124 arranged in sequence on the pipeline; Figure 4 As shown, the pumping flow control block 31 also ...

Embodiment 3

[0048] A kind of bottom filter method slag processing system of the present embodiment, basic structure is the same as embodiment 2, difference and improvement are: as Figure 4 As shown, the top of the cold water pool 34 is externally connected with a water supply pipe for the cold water pool, and a water replenishment valve is arranged on it; to control the opening and closing of the water replenishing valve to realize water replenishment in the cold water pool 34; thereby avoiding that the water level in the slag receiving filter pool 11 and the slag grabbing filter pool 12 is too high, which will bring water and slag grabbing during the slag grabbing process, resulting in vehicle transportation There will be more slag-water mixture sprinkled on the road surface in the process, cause the waste of water resources, pollute the environment; If there is less than water, the air will enter the air, which will seriously affect the life of the hot water pump ΙΙ311 and the hot wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com