River surge silt harmless and recycling treatment method

A treatment method and a resource-based technology, applied in the field of harmless treatment of silt produced by river dredging, can solve the problems of low temperature pyrolysis utilization efficiency, inability to farmland and forest land, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

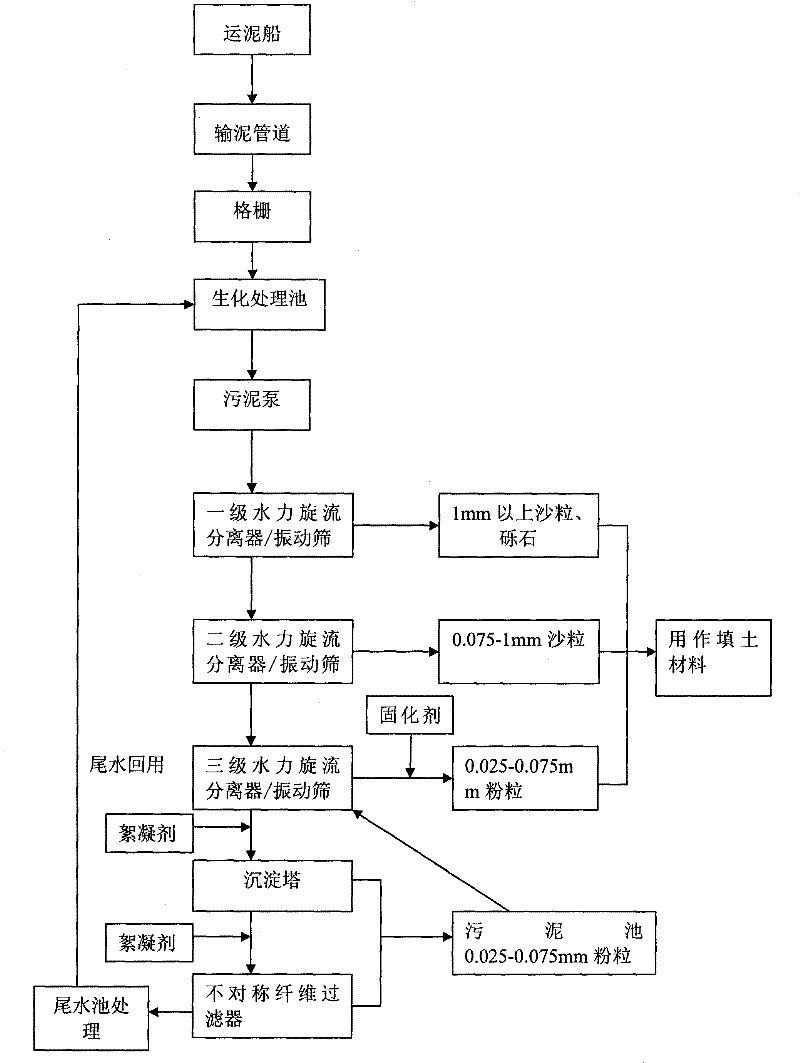

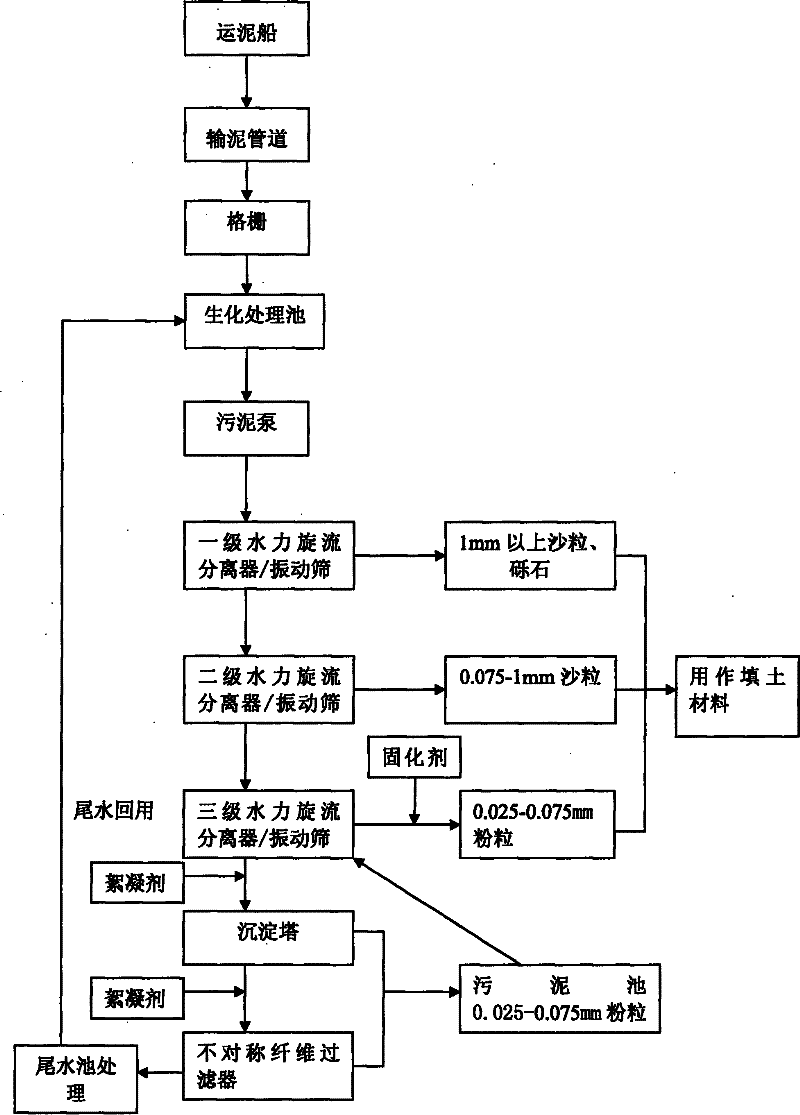

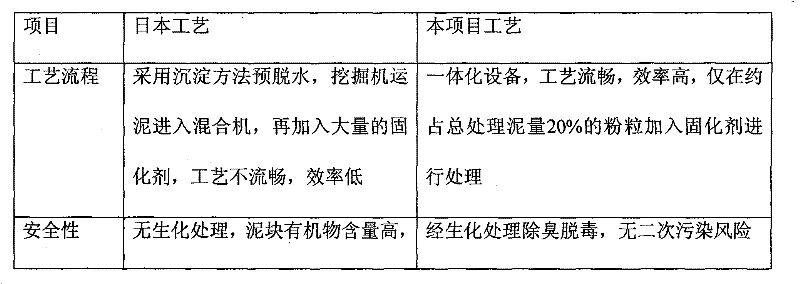

[0043] The grain size structure of river bottom mud in Guangzhou is mainly sandy, of which the content of gravel above 1mm is about 15%, the content of sand above 75um is about 65%, the content of silt grains of 25-75um is about 16%, and the content of grains below 25um is about 16%. The clay content is about 4%, and research shows that more than 90% of the organic matter and heavy metals in the river silt are adsorbed in the clay below 25um, while the gravel and sand in the river silt have low pollutant content, which can be directly used as Filling materials, in fact, the silt to be solidified accounts for about 20% of the river silt. Therefore, the harmless treatment of the river dredging sludge in Guangzhou must first consider the gravel, sand, silt, and clay in the river silt. Separately, gravel and sand are directly dried to be used as filling material, powder is added with curing agent, and then used as filling material after solidification. The process flow is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com