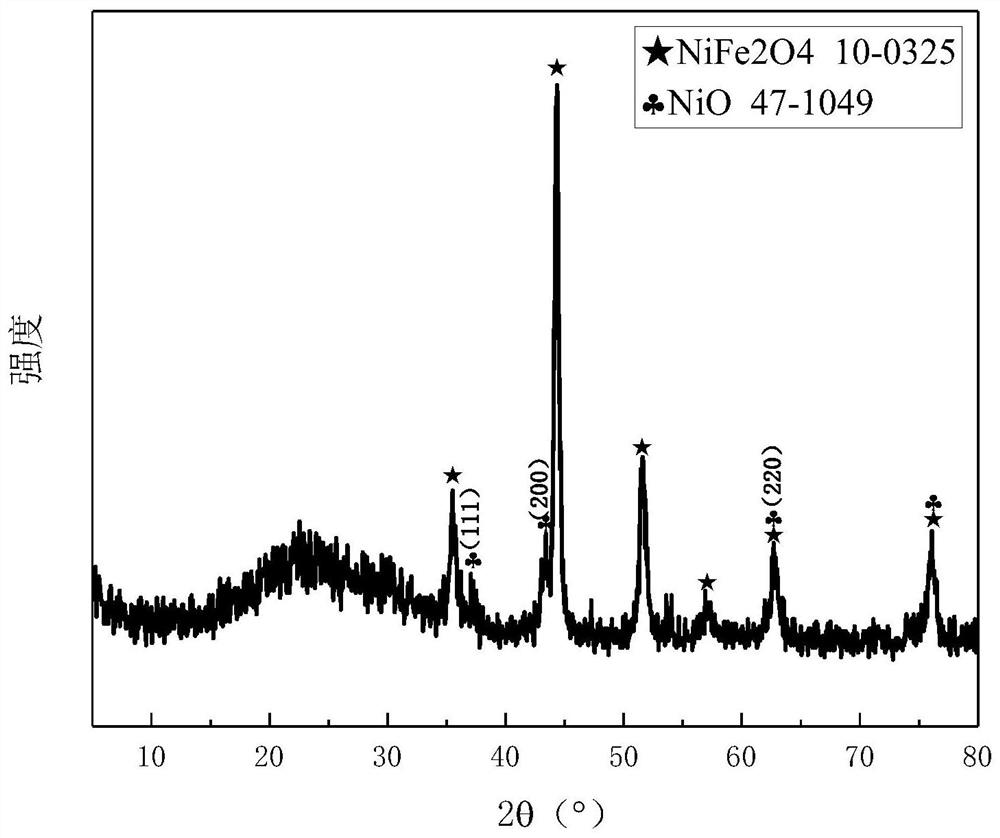

Preparation method and application of carbon-loaded NiO/NiFe2O4 spinel type solid solution electrolysis water oxygen evolution catalyst

A spinel-type, solid solution technology, applied in the field of electrochemical catalysis, can solve the problems of poor stability, high activity, unfavorable industrial application, etc., and achieve good stability, high catalytic activity, and increase the chemically active surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mixing of precursor solution: Weigh 0.0036mM nickel nitrate, 0.0012mM iron nitrate, 0.126M urea and 0.02mol NH 4 F in a beaker, add 100mL deionized water, stir for 20min to obtain a clear and transparent solution.

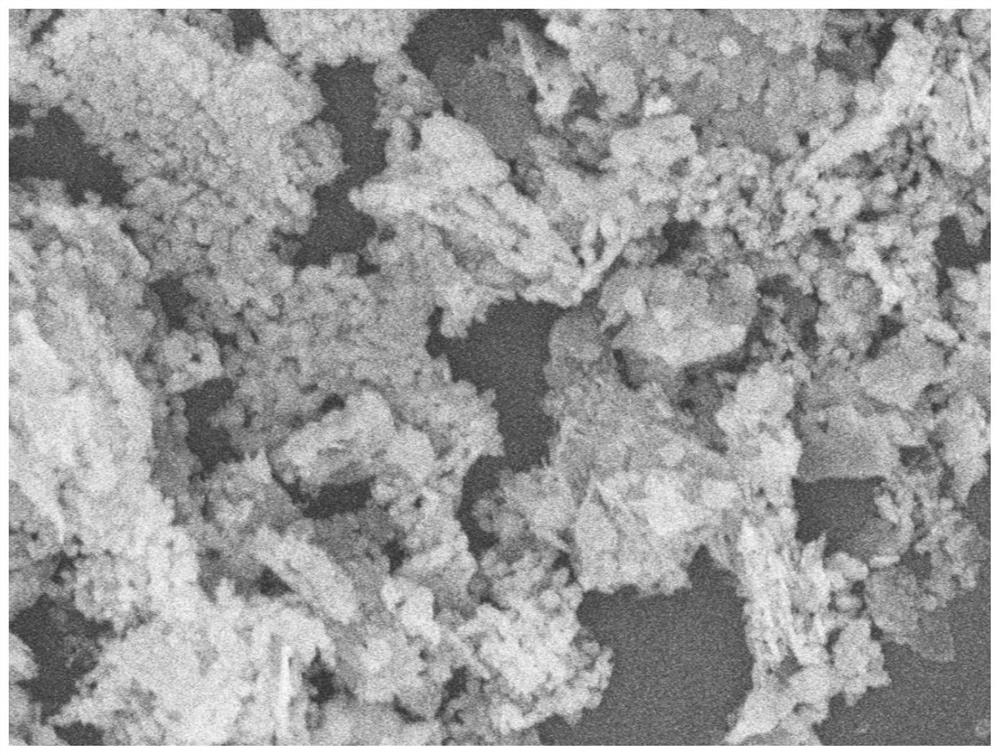

[0028] (2) Hydrothermal reaction: Transfer the solution obtained in (1) to a 100mL reaction kettle, conduct a hydrothermal reaction at 100°C for 12 hours, centrifuge and wash for 3 to 5 times, dry in vacuum for 12 hours, and grind into a fine powder.

[0029] (3) Stripping: Weigh 0.2g of the solid obtained in step (2), put it in 150mL of deionized water, use high-speed shear stirring to make it uniformly dispersed in the water, 800W intermittent ultrasonic crushing for 1h, and the finally obtained stripped NiFe-LDH suspension Cloudy liquid. Weigh 50 mg of GO and ultrasonicate at 450 W for 30 min in 150 mL of deionized water to obtain a transparent colloid of single-layer GO.

[0030] (4) Compounding: the NiFe-LDH suspension obtained in (3) was added dr...

Embodiment 2

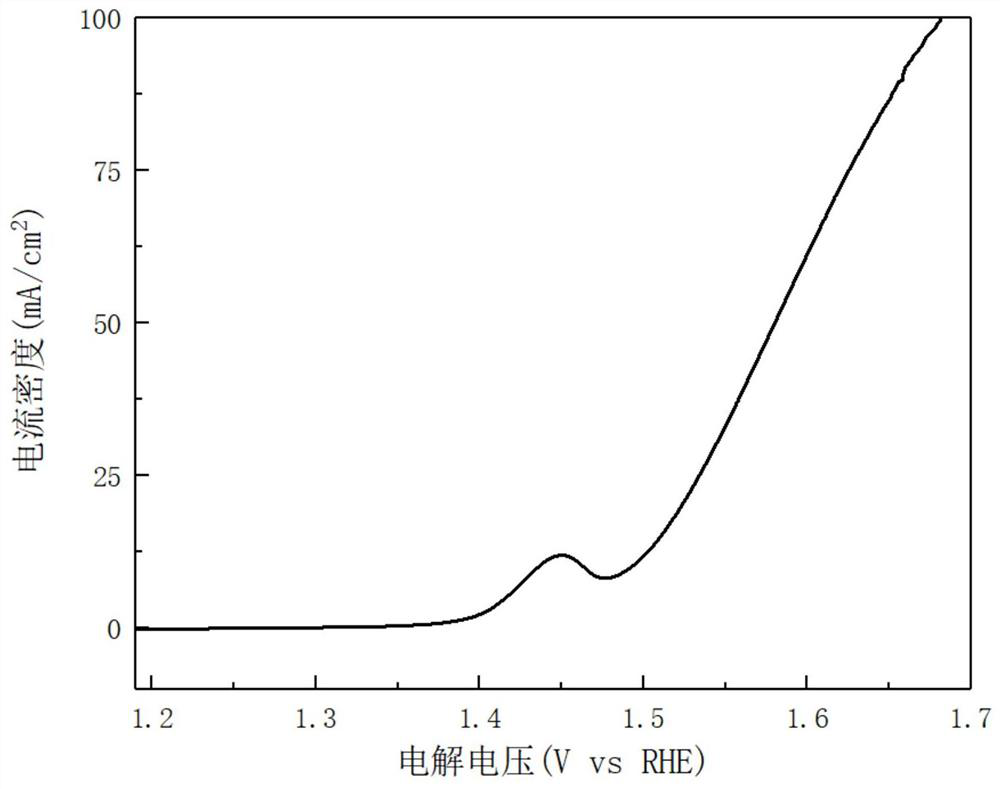

[0036] Take the same preparation process as in Example 1, and change the amount of graphene to 30 mg. The half-cell test procedure used is as described in Example 1. The NiFe-LDH / rGO prepared by this method is 10mA / cm in 1M KOH electrolyte solution 2 The overpotential under the electrolytic current density is 213mV. After continuous water electrolysis for 20 h, it exhibits excellent electrochemical durability.

Embodiment 3

[0038] Take the same preparation process as in Example 1, and change the graphene consumption to 80 mg. The half-cell test procedure used is as described in Example 1. The NiFe-LDH / rGO prepared by this method is 10mA / cm in 1M KOH electrolyte solution 2 The overpotential under the electrolytic current density is 220mV. After continuous water electrolysis for 20 h, it exhibits excellent electrochemical durability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com