Temperature-sensitive cationic liposome capable of adsorbing graphene oxide and preparation of temperature-sensitive cationic liposome

A technology of cationic liposomes and graphene, applied in the field of antitumor drugs, can solve the problems of difficulty of cationic liposomes and poor circulation ability, and achieve the effects of prolonging blood circulation time, weakening adsorption, and evading macrophage phagocytosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1,2-dipalmitoyl-sn-glycero-3-phosphocholine (DPPC), (2,3-dioleoyl-propyl)-trimethylammonium chloride (DOTAP), 1-stearyl -sn-glycero-3-phosphocholine (S-lysoPC), N-(carbonyl-methoxypolyethylene glycol 2000)-1,2-distearoyl-SN-glycero-3-phosphoethanolamine ( DSPE-mPEG2000) four kinds of phospholipids were dissolved in the organic solvent of 12mL chloroform and methanol according to the molar ratio of 66:30:2:2 (chloroform 9mL, methanol 3mL), the mass ratios of the four kinds of phospholipids were DPPC 29.068mg, DOTAP 12.573 mg, S-lysoPC 0.88 mg and DSPE-mPEG 2000 3.366 mg.

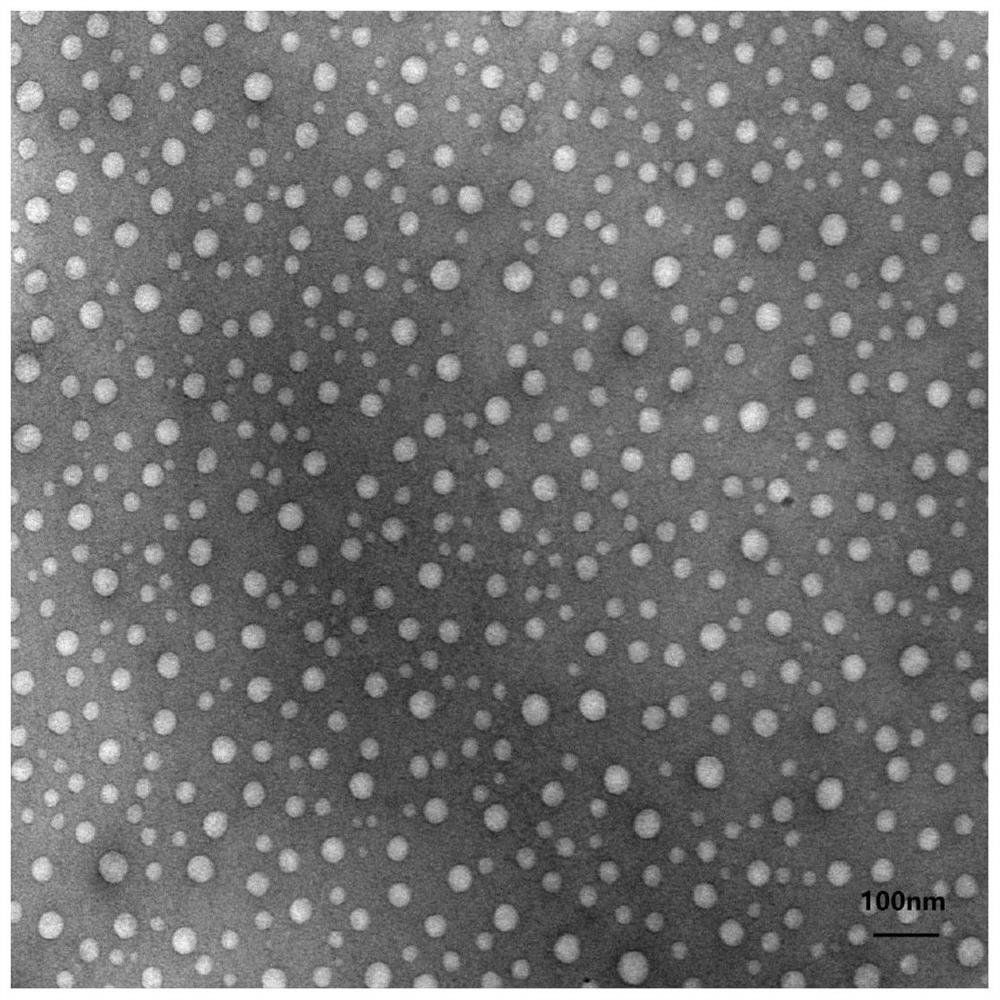

[0061] The mixture of phospholipids and organic solvents was placed in a 25mL eggplant-shaped flask for rotary evaporation. The speed of the film gradient pressure method is 48r / min, the rotary evaporation temperature is 45°C, the rotary evaporation gradient pressure is 0.02, 0.04, 0.06, 0.08, 0.1MPa, and the rotary evaporation time at the gradient pressure is 50min, 35min, 22min, 22min, 18min. Hydr...

Embodiment 2

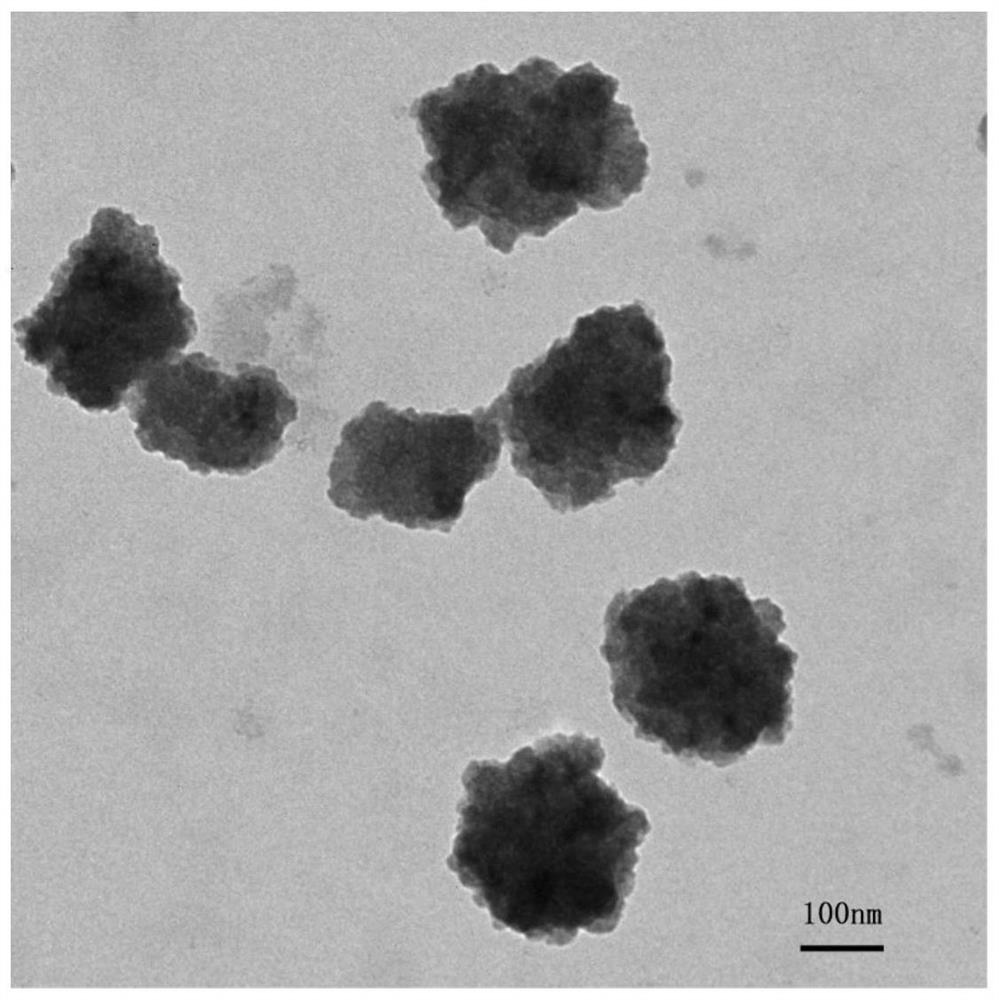

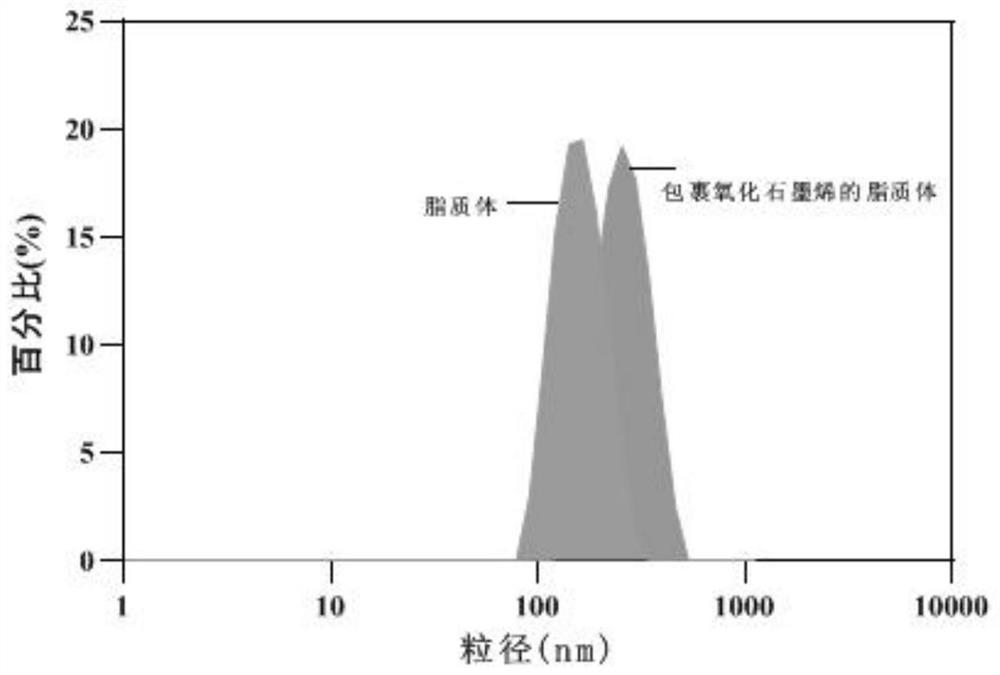

[0066] Dissolve 10 mg graphene oxide in 10 mL H 2 O, the solution was ultrasonically crushed to the nanometer level, the ultrasonic power was 800W, the ultrasonic wave was 2s, the interval was 2s, and the ultrasonication time was 18h. The graphene oxide used has a thickness of 2-10 nm, a particle diameter of 80-150 nm, and a potential of -40-30 mV.

[0067] Add 2mL of 4mg / mL temperature-sensitive cationic liposome solution into a NaCl solution with a pH of 7.4, an ion concentration of 10nmol, and a volume of 6mL, and stir magnetically for 30min to obtain reaction solution 3. The magnetic stirring speed is 175r / min and the temperature is 25°C .

[0068] 2 mL of 1 mg / mL graphene oxide was dropped dropwise into the reaction solution 3, and after the electrostatic adsorption reaction was carried out at a speed of 175 r / min and a temperature of 25 °C for 48 h, centrifuged at a speed of 14000 r / min for 15 min to obtain Temperature-sensitive cationic liposomes adsorbed on graphene ...

Embodiment 3

[0071] 1,2-dipalmitoyl-sn-glycero-3-phosphocholine (DPPC), (2,3-dioleoyl-propyl)-trimethylammonium chloride (DOTAP), 1-stearyl -sn-glycero-3-phosphocholine (S-lysoPC), N-(carbonyl-methoxypolyethylene glycol 2000)-1,2-distearoyl-SN-glycero-3-phosphoethanolamine ( DSPE-mPEG2000) four kinds of phospholipids were dissolved in the organic solvent of 12mL chloroform and methanol according to the molar ratio of 66:30:2:2 (chloroform 9mL, methanol 3mL), the mass ratios of the four kinds of phospholipids were DPPC 29.068mg, DOTAP 12.573 mg, S-lysoPC 0.88 mg and DSPE-mPEG 2000 3.366 mg.

[0072] Mix 23mg of hydrophobic tumor chemotherapy drug quercetin with phospholipid organic solution.

[0073] The mixture of phospholipids, quercetin and organic solvent was placed in a 25mL eggplant-shaped flask for rotary evaporation. The speed of the film gradient pressure method is 48r / min, the rotary evaporation temperature is 45°C, the rotary evaporation gradient pressure is 0.02, 0.04, 0.06, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com