Total synthesis grinding fluid and preparation method thereof

A kind of grinding fluid, fully synthetic technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems that it is difficult to meet the needs of lubrication and anti-rust, the performance of lubricant and anti-rust agent is single, and the anti-rust agent is harmful to human body, etc. Achieve the effects of simple and controllable production process, outstanding anti-rust performance, and enhanced anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

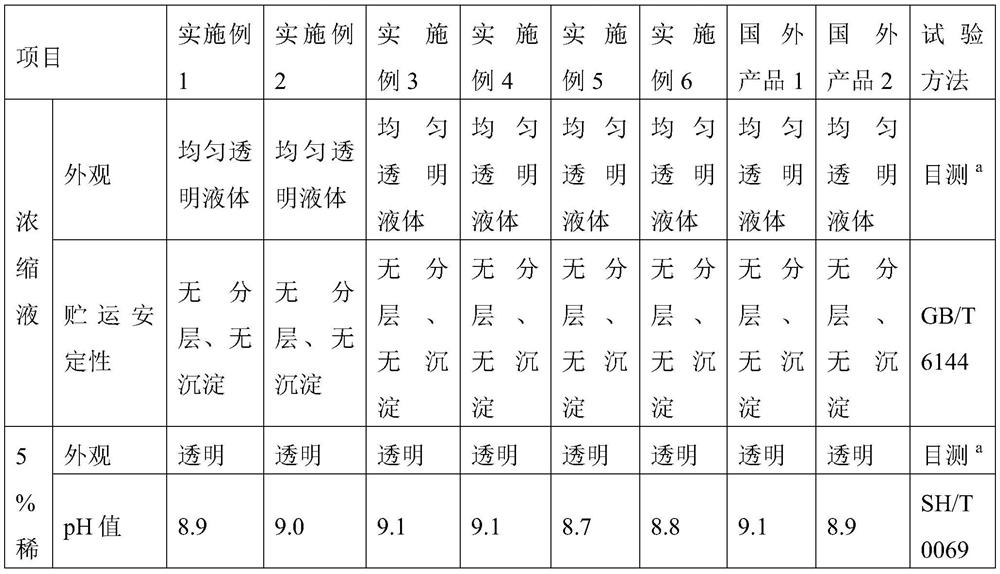

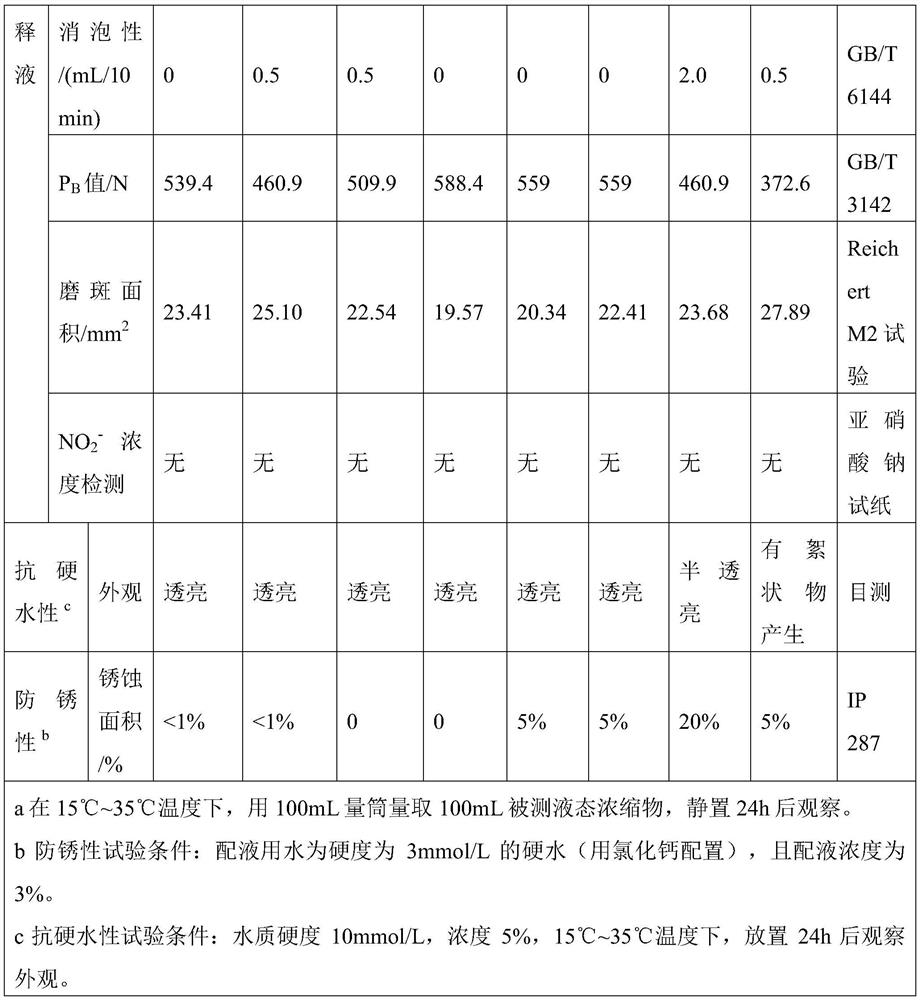

Examples

preparation example Construction

[0046] In addition, the present invention also provides the preparation method of above-mentioned fully synthetic grinding fluid, and this preparation method comprises the following steps:

[0047]At normal temperature (for example, 15-35°C), add the composite antirust agent and preservative into water, then add the organic alcohol amine, stir until the solid powder is completely dissolved, then add the composite lubricant, and stir until the system is uniform and transparent. Fully synthetic grinding fluid.

[0048] Among them, the water used in the fully synthetic grinding fluid of the present invention is preferably demineralized water, that is, water from which some or all inorganic salts, such as calcium and magnesium salts, have been removed. Generally speaking, the content of magnesium carbonate and calcium carbonate in demineralized water is in the range of 0-60ppm in terms of "mg magnesium carbonate / kg water" or "ppm".

[0049] Thus, the preparation method of the ful...

Embodiment 1

[0052] A fully synthetic grinding fluid and its preparation process, each component, weight percentage and preparation process are:

[0053] 8% compound lubricant, 8% compound antirust agent, 19% organic alcohol amine, 0.2% preservative and 64.8% demineralized water.

[0054] Among them, the composite lubricant is block polymer RPE1720 containing 2%, phosphate ester LP700 containing 3%, polyether ester PRIOLUBE 3955 containing 3%, the composite antirust agent is octanoic acid 1%, undecane dibasic acid 2%, 5% polycarboxylic acid, 4% diglycolamine, 14% triethanolamine, 1% 2-amino-2methyl-1-propanol, 0.2% benzotriazole as preservative, Softened water 64.8%.

[0055] The preparation process is as follows: at room temperature (15-35°C), add 1% n-octanoic acid, 2% undecanedibasic acid, 5% terpolymeric acid, and 0.2% benzotriazole to 64.8% demineralized water. Then add diglycolamine 4%, triethanolamine 14%, 2-amino-2 methyl-1-propanol 1%, stir until the solid powder is completely d...

Embodiment 2

[0057] A fully synthetic grinding fluid and its preparation process, each component, weight percentage and preparation process are:

[0058] Composite lubricant 5%, composite antirust agent 8%, organic alcohol amine 19%, preservative 0.3% and demineralized water 67.7%.

[0059] Among them, the composite lubricant is block polymer RPE1720 containing 2%, polyether ester K9320 containing 3%, the composite antirust agent is neodecanoic acid 1%, dodecanoic acid 2%, ternary polycarboxylic acid 5% , the organic alcohol amine is 4% of monoethanolamine, 15% of diisopropanolamine, the preservative is 0.3% of tolyltriazole derivative, and the demineralized water is 67.7%.

[0060] The preparation process is as follows: at room temperature (15-35°C), add 1% neodecanoic acid, 2% dodecanoic acid, 5% terpolymeric acid, and tolyltriazole to 67.7% demineralized water. 0.3% of derivatives, then add 4% of monoethanolamine and 15% of diisopropanolamine, stir until the solid powder is completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com