Preparation method of titanium alloy plate

A titanium alloy and plate technology, applied in the field of titanium alloy plate preparation, can solve the problems of unrealized industrial production and application, ingot pretreatment shaping and rolling process parameters are not clear, etc., to achieve small grain size, reduce steps, microstructure good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of titanium alloy plate (1)

[0038] (1) Using 0-grade sponge titanium and high-quality intermediate alloy aluminum and vanadium, carry out the alloy ratio according to TC4 (Ti-6Al-4V), press the alloy with a good ratio on a 3000-ton hydraulic press to form an alloy block, and put it in a vacuum welding box welded into electrodes. The consumable vacuum electric arc furnace (VAR furnace) is used for three times of smelting, and the obtained ingot is turned and peeled by a lathe, and the riser is sawed to obtain a finished alloy ingot.

[0039](2) Heat the ingot to 850°C in a box-type resistance heating furnace and keep it for 100 minutes; then increase the temperature to 1150°C and keep it for 500 minutes. The heated ingot is shaped on a 4500T press, and the cylindrical ingot is pressed into a rectangular billet with a thickness of 300mm. After air-cooling, use a grinding and polishing machine to polish off the scale and debris on the surface ...

Embodiment 2

[0042] Embodiment 2: the preparation of titanium alloy plate (two)

[0043] (1) Use 0-grade sponge titanium and high-quality master alloy aluminum, iron, chromium, tin and silicon, according to TC611 (Ti-(4-7)Al-(0.2-2.5)Fe-(0.1-2)Cr-(0.1 -2) Sn-(0.1-0.5)Si) is used for alloy proportioning, and the proportioned alloy is pressed into an alloy block on a 3,000-ton hydraulic press, and then welded into an electrode in a vacuum welding box. The consumable vacuum electric arc furnace (VAR furnace) is used for three times of smelting, and the obtained ingot is turned and peeled by a lathe, and the riser is sawed to obtain a finished alloy ingot.

[0044] (2) Heat the ingot to 800°C in a box-type resistance heating furnace and keep it warm for 100 minutes; then raise the temperature to 1000°C and keep it warm for 500 minutes. The heated ingot is shaped on a 4500T press, and the round ingot is pressed into a rectangular billet with a thickness of 200mm. After air-cooling, use a grin...

Embodiment 3

[0047] Embodiment 3: the detection of the titanium alloy sheet material that embodiment 1 and embodiment 2 make

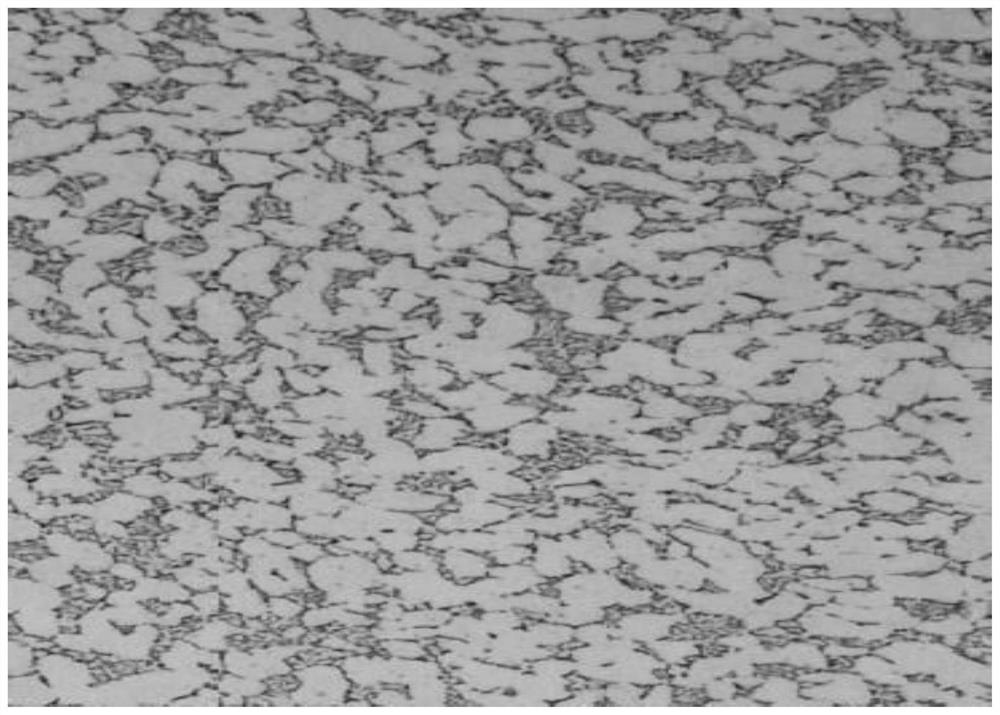

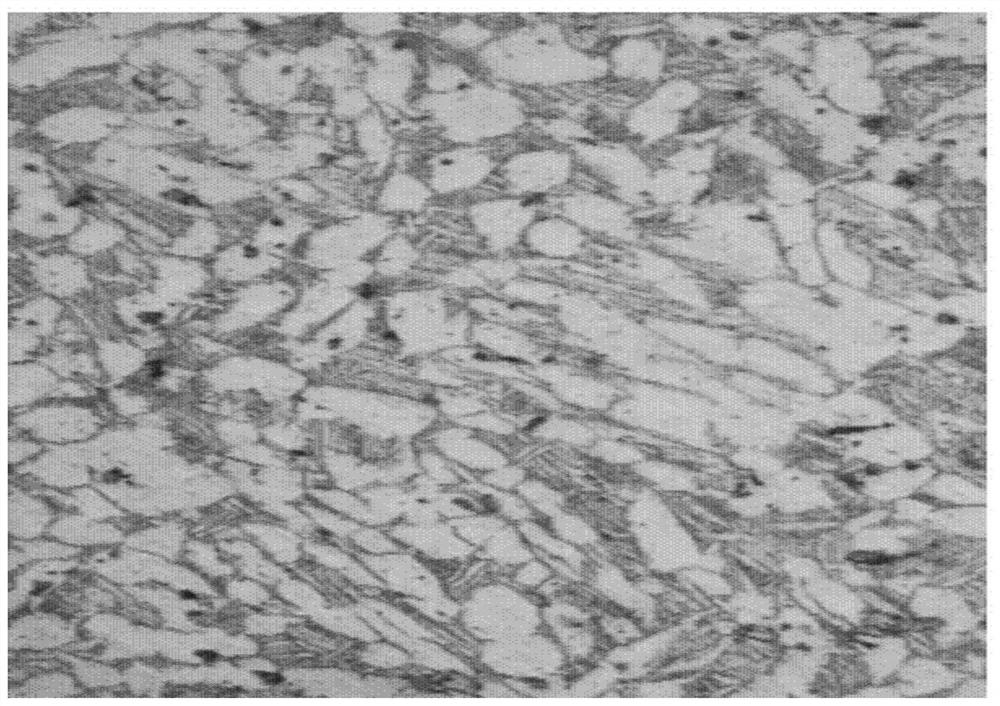

[0048] The microstructure topography diagrams of the titanium alloy plates prepared in Examples 1 and 2 are respectively as follows: figure 1 , 2 shown. From figure 1 and figure 2 It can be seen that the distribution of each phase inside the finished plate is uniform, and an ideal, fine equiaxed structure is obtained; after annealing, the plate achieves complete recrystallization, and the grain distribution is uniform, which meets the supply demand of titanium alloy plates.

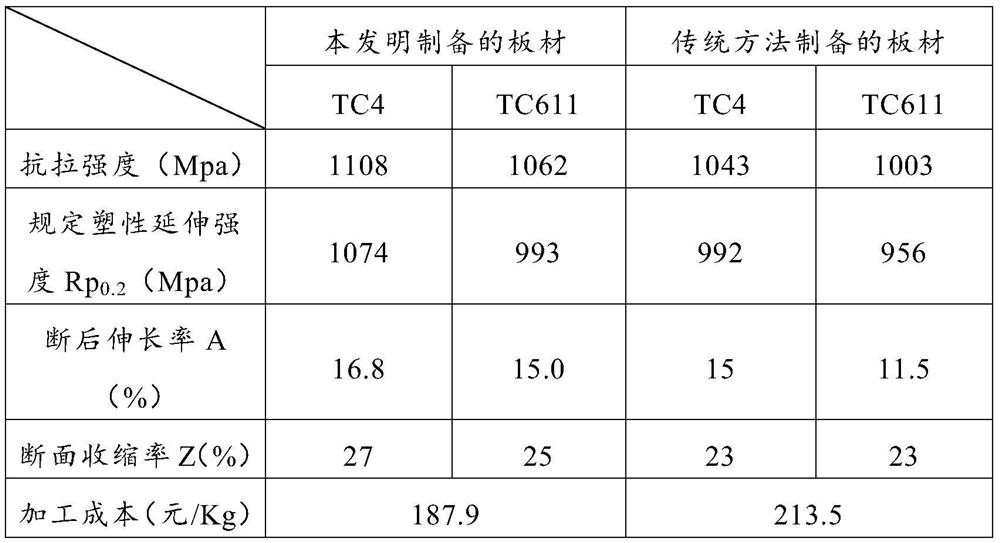

[0049] Table 1 is according to the traditional process (ingot smelting-heating-forging upsetting-returning upsetting-air cooling grinding-heating upsetting-repair-heating forging-planing milling-heating-rolling-heat treatment-acid and alkali cleaning-cutting planer Milling-finished product) prepared TC4 and TC611 titanium alloy plates (wherein the ingot smelting, acid-base cleaning and fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com