Preparation method of nuclear-grade nickel-based high-temperature alloy welding wire material

A technology of nickel-based superalloy and welding wire, which is applied in the field of metal material melting, can solve the problems of reducing the mechanical properties of the alloy and the content of non-metallic elements, and achieves the effects of reliable quality, improved purity and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of a nuclear-grade nickel-based superalloy welding wire material, comprising the steps of:

[0024] The first step alloy composition design:

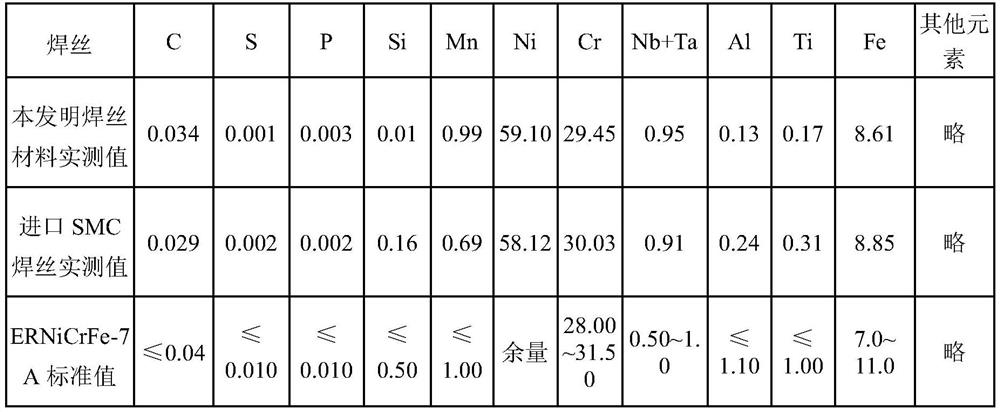

[0025] In terms of mass percentage, the alloy composition is: C0.034%, Mn0.99%, Fe8.61%, Cr29.45%, Mo0.4%, Si0.01%, Nb+Ta0.95%, Al0. 13%, Ti0.17%, Co≤0.02%, N≤0.02%, H≤2PPM, O≤30PPM, Co+N+V≤0.5%, Ni balance and trace impurity elements; the impurity elements are expressed in mass percentage Meet the following requirements: S≤0.003%, P≤0.003%, B≤0.003%, As≤0.001%, Sn≤0.0025%, Sb≤0.0025%, Cu≤0.02%, Pb≤0.0025%;

[0026] The second step is raw material selection:

[0027] Selection of raw materials with content of S, P, B, Co, As, Sn, Sb, Cu, Pb elements meeting the following requirements: S≤0.003%, P≤0.003%, B≤0.003%, Co≤0.02%, As≤0.001 %, Sn≤0.0025%, Sb≤0.0025%, Cu≤0.02%, Pb≤0.0025%; raw materials are metal chromium, metal nickel, 1# pure iron, metal tantalum, metal niobium, metal aluminum, metal titanium, gr...

Embodiment 2

[0039] A preparation method of a nuclear-grade nickel-based superalloy welding wire material, comprising the steps of:

[0040] The first step alloy composition design:

[0041] In terms of mass percentage, the alloy composition is: C0.04%, Mn0.60%, Fe7.00%, Cr28.0%, Mo0.30%, Si0.10%, Nb+Ta1.0%, Al0. 25%, Ti0.35%, Co0.02%, N0.02%, H2PPM, O30PPM, Co+N+V 0.5%, Ni balance and trace impurity elements; the impurity elements meet the following requirements in mass percentage: S≤0.003%, P≤0.003%, B≤0.003%, As≤0.001%, Sn≤0.0025%, Sb≤0.0025%, Cu≤0.02%, Pb≤0.0025%;

[0042] The second step is raw material selection:

[0043] Selection of raw materials with content of S, P, B, Co, As, Sn, Sb, Cu, Pb elements meeting the following requirements: S≤0.003%, P≤0.003%, B≤0.003%, Co≤0.02%, As≤0.001 %, Sn≤0.0025%, Sb≤0.0025%, Cu≤0.02%, Pb≤0.0025%; raw materials are metal chromium, metal nickel, 1# pure iron, metal tantalum, metal niobium, metal aluminum, metal titanium, graphite block, Metal...

Embodiment 3

[0051] A preparation method of a nuclear-grade nickel-based superalloy welding wire material, comprising the steps of:

[0052] The first step alloy composition design:

[0053] In terms of mass percentage, the alloy composition is: C0.04%, Mn0.60%, Fe7.00%, Cr28.0%, Mo0.30%, Si0.10%, Nb+Ta1.0%, Al0. 25%, Ti0.35%, Co0.02%, N0.02%, H 2PPM, O30PPM, Co+N+V 0.5%, Ni balance and trace impurity elements; the impurity elements meet the following requirements in mass percentage : S≤0.003%, P≤0.003%, B≤0.003%, As≤0.001%, Sn≤0.0025%, Sb≤0.0025%, Cu≤0.02%, Pb≤0.0025%;

[0054] The second step is raw material selection:

[0055] Selection of raw materials with content of S, P, B, Co, As, Sn, Sb, Cu, Pb elements meeting the following requirements: S≤0.003%, P≤0.003%, B≤0.003%, Co≤0.02%, As≤0.001 %, Sn≤0.0025%, Sb≤0.0025%, Cu≤0.02%, Pb≤0.0025%; raw materials are metal chromium, metal nickel, 1# pure iron, metal tantalum, metal niobium, metal aluminum, metal titanium, graphite block, Met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com