Bubble hair conditioner

A hair conditioner and bubble technology, applied in the field of daily chemicals, can solve problems such as high toxicity, damage to hair follicles, hair loss and hair loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

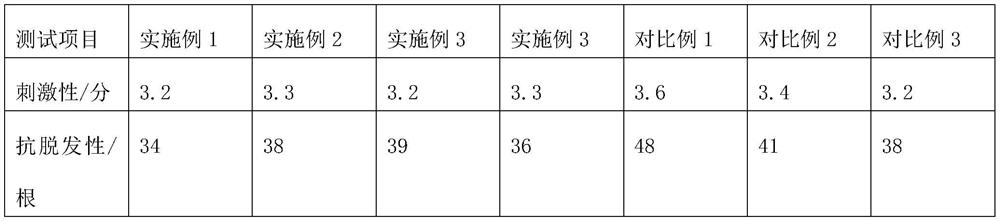

Examples

Embodiment 1

[0024] A bubble conditioner, comprising the following components calculated by mass percentage: saponin 1.5%, decyl glucoside 8%, trideceth-12 0.5%, stearyl trimethyl ammonium chloride 1 %, cetrimonium chloride 0.5%, glycerin 5%, sodium pyrrolidone carboxylate 3%, panthenol 0.5%, sugar isomers 1.5%, proline 1%, lactic acid 1%, amino-terminal polyethylene dimethyl 1% polysiloxane, 0.5% ginger extract, 1% dandelion extract, 1% Polygonum multiflorum extract, 0.1% methylparaben and the rest water.

Embodiment 2

[0026] A bubble conditioner, comprising the following components calculated by mass percentage: saponin 1.5%, decyl glucoside 8%, trideceth-12 0.5%, stearyl trimethylammonium chloride 1.5% %, glycerin 5%, sodium pyrrolidone carboxylate 3%, panthenol 0.5%, sugar isomers 1.5%, proline 1%, lactic acid 1%, amodimethicone 1%, 0.5% ginger extract, 1% dandelion extract, 1% Polygonum multiflorum extract, 0.1% methyl paraben and the rest water.

Embodiment 3

[0028] A bubble conditioner, comprising the following components calculated by mass percentage: saponin 1.5%, decyl glucoside 8%, trideceth-12 0.5%, stearyl trimethyl ammonium chloride 1 %, Cetrimonium Chloride 0.5%, Glycerin 5%, Sodium Pyrrolidone Carboxylate 3%, Sugar Isomers 2%, Proline 1%, Lactic Acid 1%, Amodimethicone 1 %, 0.5% of ginger extract, 1% of dandelion extract, 1% of Polygonum multiflorum extract, 0.1% of methylparaben and the rest of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com