A kind of method of recovering ammonia from coking wastewater

A technology for coking wastewater and ammonia recovery, applied in the field of ammonia recovery, can solve the problems of complex process, large investment, high process and equipment safety requirements, etc., achieve good ammonia removal effect, low investment cost, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

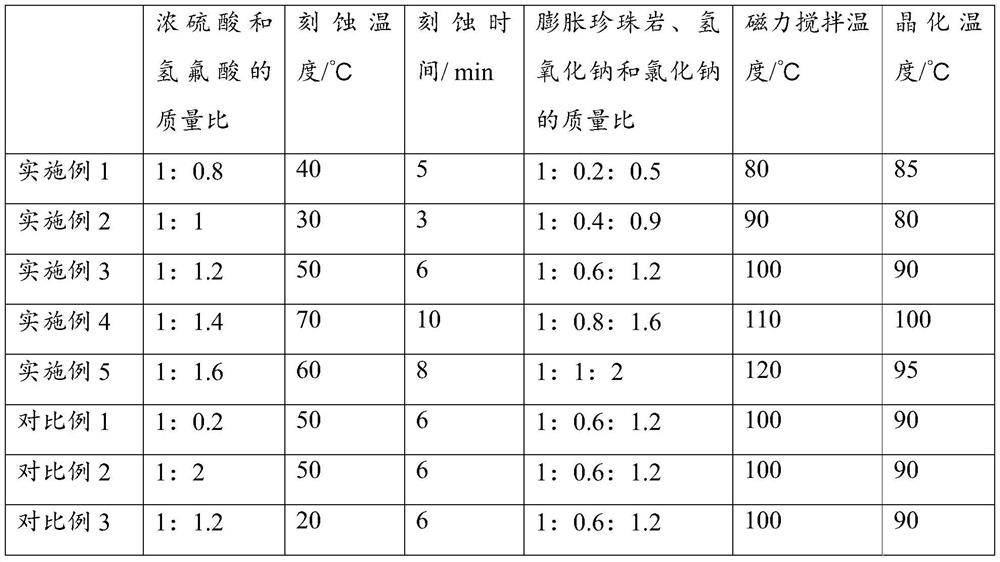

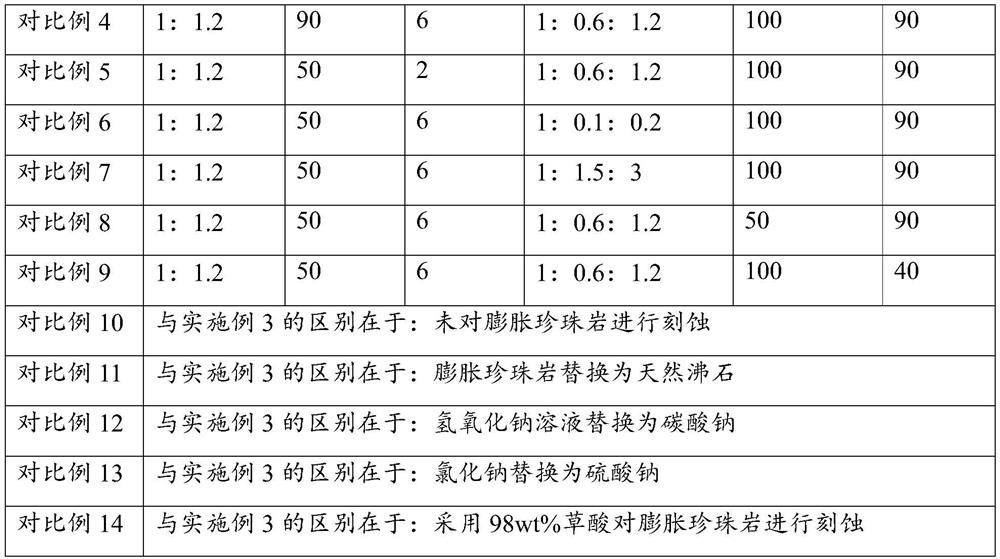

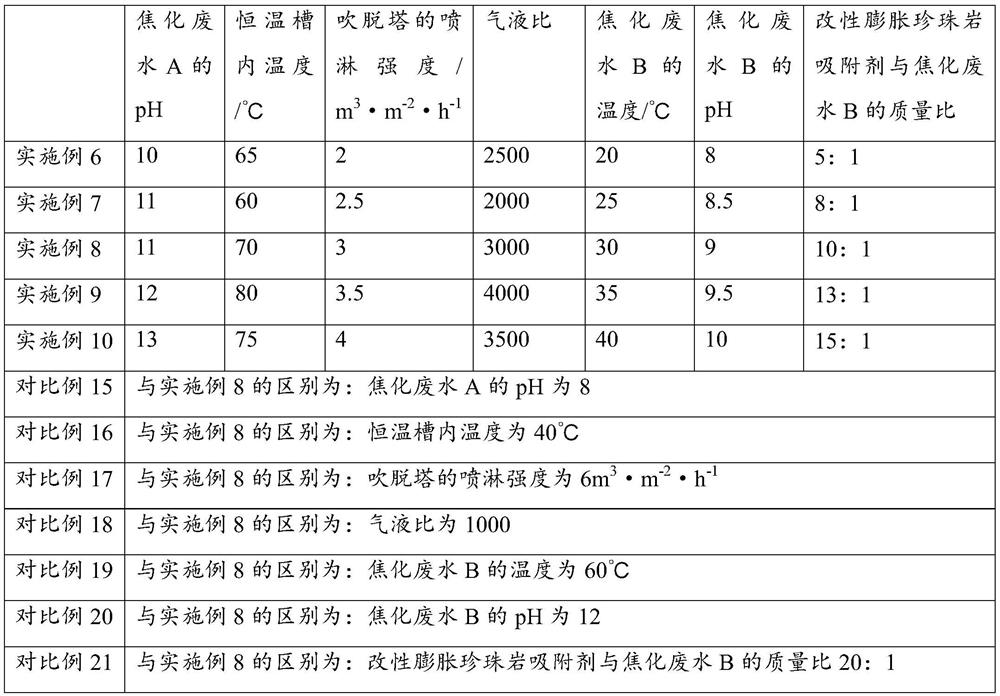

[0029] The present application will be described in detail below with reference to the examples, but the present application is not limited to these examples.

[0030] The mass fraction of hydrofluoric acid in this application is 30%, the mass fraction of concentrated sulfuric acid is 98%, and the concentration of sodium chloride is 1 mol / L.

[0031] In one embodiment, a method for recovering ammonia from coking wastewater, comprising the steps of:

[0032] (1) The coking wastewater is introduced into a constant temperature tank, and an appropriate amount of sodium hydroxide is added to the coking wastewater to obtain a coking wastewater A. The ammonia concentration of the coking wastewater A is 20 mg / L, the temperature in the tank is 60 to 80 ° C, and the pH of the coking wastewater A is is 10 to 13;

[0033] (2) The coking wastewater A is introduced into the stripping tower for ammonia recovery, and the spray intensity of the stripping tower is 2 to 4 m 3 m -2 ·h -1 , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com