Preparation method of sulfur antimony selenide thin film

A technology of antimony selenide and thin film, which is applied in the direction of coating, etc., can solve the problems of poor process repeatability, many crystal defects, poor crystallinity of thin film, etc., and achieve the effect of improving device performance, simple preparation process and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

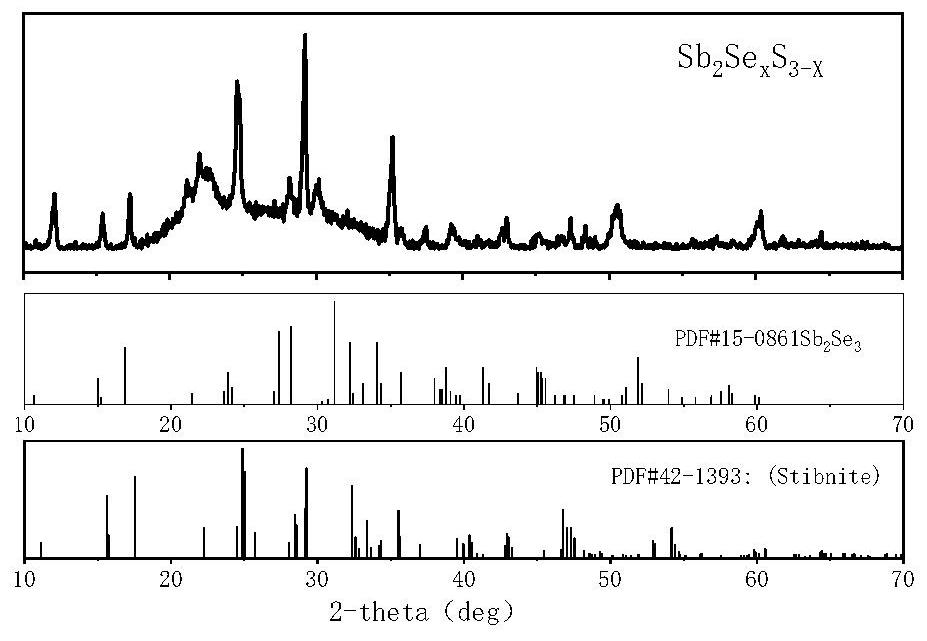

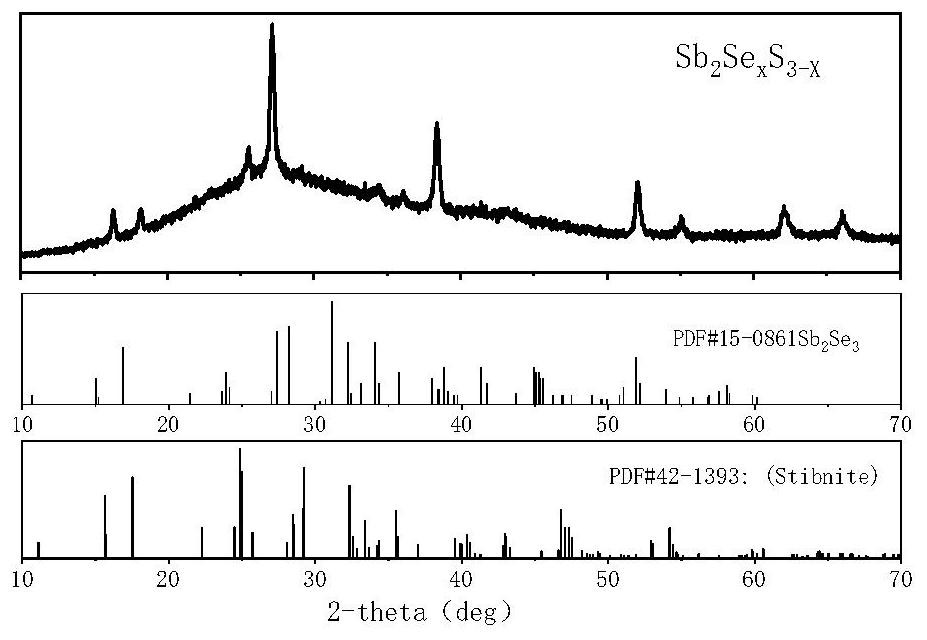

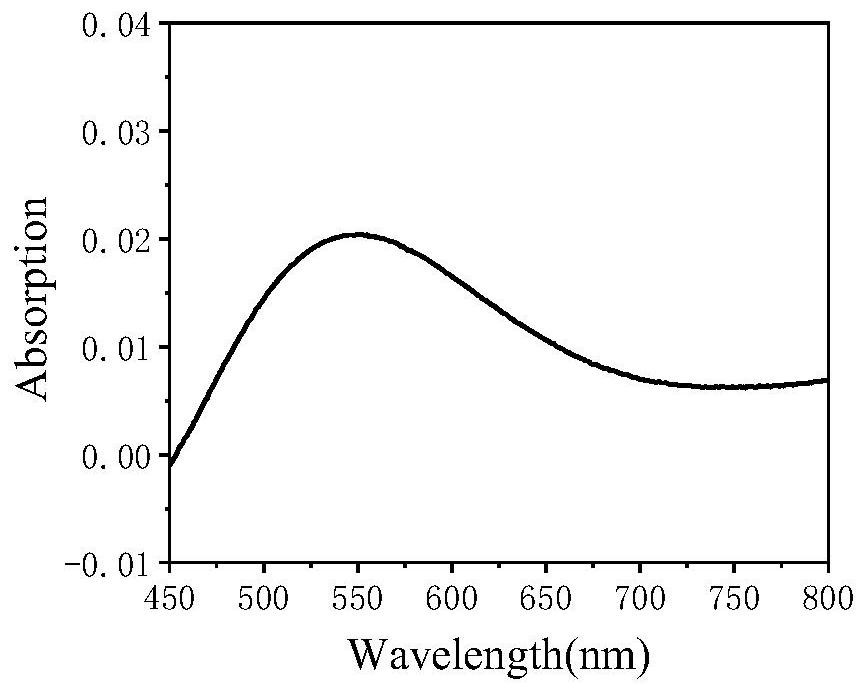

Image

Examples

preparation example Construction

[0035] A kind of preparation method of antimony sulfur selenide film provided by the invention comprises the following steps:

[0036] (1) Ethylenediamine and ethanedithiol are mixed at a volume ratio of 1:10, and then antimony selenide is added to the above mixed solution to obtain an electrodeposition solution;

[0037] (2) Add the electrodeposition liquid that step (1) makes in the electrolytic tank, place two conductive glasses vertically relative to the liquid level in the electrolytic tank, and keep the two conductive glasses parallel to each other;

[0038] (3) Carry out constant potential electrodeposition to two pieces of conductive glass, make the electrode surface on the conductive glass on the cathode deposit a layer of prefabricated film;

[0039] (4) heat-treating the conductive glass deposited with the prefabricated film in a nitrogen atmosphere, and naturally cooling to room temperature to obtain an antimony sulfur selenide thin film.

[0040] In the present i...

Embodiment 1

[0050] A preparation method of antimony sulfoselenide film, comprising the steps of:

[0051] (1) Use acetone, ethanol solution and deionized water to ultrasonically clean the ITO conductive glass for 15 minutes in sequence, and dry it for later use;

[0052] (2) Add 0.01g Sb 2 Se 3 Dissolve in a mixed solution of 7 ml of ethylenediamine and 0.7 ml of ethanedithiol, and stir at room temperature until Sb 2 Se 3 Dissolve completely to obtain electrodeposition solution;

[0053] (3) Add electrodeposition solution into the electrolytic tank, use two ITO conductive glasses with a size of 1cm×2cm as working electrodes, place the two conductive glasses vertically relative to the liquid surface in the electrolytic tank, and keep the two conductive glasses mutually parallel;

[0054] (4) Carry out constant potential deposition to two ITO conductive glasses with a potentiostat, the deposition voltage is 4V, and the deposition time is 5min. After the deposition is over, a layer of u...

Embodiment 2

[0057] A preparation method of antimony sulfoselenide film, comprising the steps of:

[0058] (1) Use acetone, ethanol solution and deionized water to ultrasonically clean the FTO conductive glass for 15 minutes in sequence, and dry it for later use;

[0059] (2) Add 0.03g Sb 2 Se 3 Dissolve in a mixed solution of 7 ml of ethylenediamine and 0.7 ml of ethanedithiol, and stir at room temperature until Sb 2 Se 3 Dissolve completely to obtain electrodeposition solution;

[0060] (3) Add electrodeposition solution into the electrolytic tank, use two ITO conductive glasses with a size of 1cm×2cm as working electrodes, place the two conductive glasses vertically relative to the liquid surface in the electrolytic tank, and keep the two conductive glasses mutually parallel;

[0061] (4) Carry out constant potential deposition to two ITO conductive glasses with a potentiostat, the deposition voltage is 2V, and the deposition time is 10min. After the deposition is over, a layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com