Preparation method of perfluorinated sulfonic acid resin solid

A perfluorosulfonic acid resin and solid technology, which is applied in the field of preparation of perfluorosulfonic acid resin solids, can solve the problems of large sewage, limited cleaning effect of water washing, and difficulty in removing lipophilic and hydrophobic impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

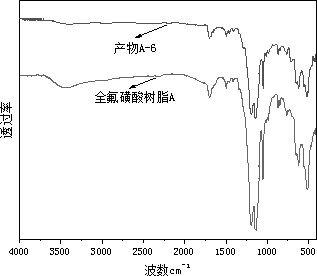

Image

Examples

preparation example Construction

[0062] A kind of preparation method of perfluorosulfonic acid resin solid of the embodiment of the present invention, comprises:

[0063] a, dispersing the perfluorosulfonic acid resin in a solvent to obtain a perfluorosulfonic acid resin dispersion;

[0064] b. Add the perfluorosulfonic acid resin dispersion obtained in step a into an organic precipitant, precipitate and filter to obtain a solid product, and the organic precipitant is selected from the first precipitant, the second precipitant or the third precipitant At least one of the agents, wherein, the first precipitation agent is selected from carbon five alkanes, carbon six alkanes, carbon seven alkanes, carbon eight alkanes, carbon nine alkanes, carbon ten alkane, perfluoro-n-hexane or petroleum ether At least one, the second precipitation agent is selected from carbon disulfide, methylene chloride, carbon tetrachloride, chloroform, ethyl chloride, C 2 h 4 Cl 2 、C 2 h 3 Cl 3 、C 3 h 7 Cl, C 4 h 9 Cl or C 5 ...

Embodiment 1

[0118] Example 1 Using different solvents to dissolve and disperse perfluorosulfonic acid resins to obtain solid perfluorosulfonic acid resins

[0119] Weigh 1 g of perfluorosulfonic acid resin A into 9 g of solvent, and dissolve under certain conditions to obtain a clear and transparent dispersion. The dispersion was added to 25 g of n-hexane to obtain a precipitate. The precipitate was vacuum-dried at 180 °C for 4 h, and the solid perfluorosulfonic acid resin was obtained after drying.

[0120] The structural formula of perfluorosulfonic acid resin A in the present embodiment is:

[0121]

[0122] Solvents used for resin dissolution and dispersion in this embodiment include water, methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, ethylene glycol, 1,2 propylene glycol, 1,3 propylene glycol, glycerol At least one of alcohol, N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc), dimethylsulfoxide (DMSO) and N-methylpyrrolidone (NMP).

[0123] In orde...

Embodiment 2

[0131] Embodiment 2: adopt the organic precipitant that contains the first precipitant to make perfluorosulfonic acid resin solid

[0132] Weigh 80 g of perfluorosulfonic acid resin B and put it into 320 g of solvent. The solvent used is dimethyl sulfoxide and isopropanol with a mass ratio of 1:2. Dissolve at 60 °C for 1 h under normal pressure. Obtained 400 g of clear and transparent dispersion liquid W. 5 g of dispersion W was added to 15 g of different types of precipitants to obtain precipitation. The precipitate was air-dried at 220 °C for 0.5 h, and the solid perfluorosulfonic acid resin was obtained after drying.

[0133] The structural formula of perfluorosulfonic acid resin B in the present embodiment is:

[0134]

[0135] The organic precipitant used in this embodiment includes the first precipitant, specifically n-pentane, n-hexane, cyclohexane, perfluoro-n-hexane, a mixture of two carbon hexanes, petroleum ether, industrial hexane, industrial heptane And the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com