Preparation process of modified cellulose nanofibril/polymer composite material

A technology of nanofibrils and composite materials, applied in the field of plant-based nanofiber composite materials, which can solve problems such as poor compatibility and cumbersome composite processes, and achieve the effects of improving mechanical properties, simplifying production processes, and better transmitting and absorbing external stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

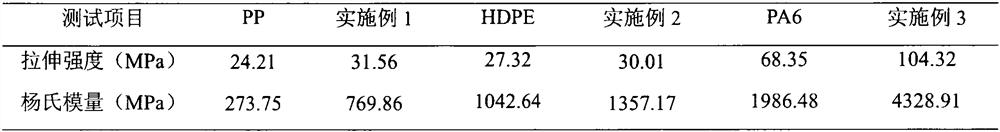

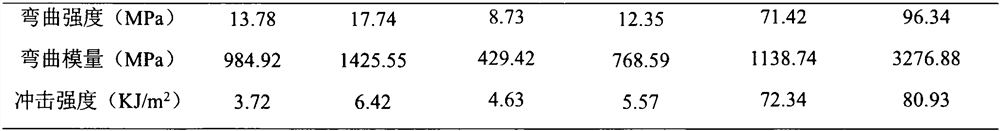

Embodiment 1

[0025] Prepare the modified CNF / PP composite material according to the following method, the steps are as follows:

[0026] 1. Hydrophobic modification of dissolving pulp by acetylation

[0027] ①Weigh 200g of dissolved pulp board, shred it, soak it in deionized water for 4 hours, beat it according to QB / T3703-1999, and dry it at room temperature for later use;

[0028] ② Accurately weigh 10 g of the dissolving slurry in step ①, place it in a round bottom flask equipped with a condensation reflux device, add 100 ml of glacial acetic acid, 0.5 g of concentrated sulfuric acid and 9.5 g of acetic anhydride, and mix well;

[0029] ③ Place the mixture in step ② in a water bath at 50°C for 1 hour; after the reaction, centrifuge and wash repeatedly at 5000r / min until the supernatant is neutral;

[0030] ④ Measure the moisture content of the product in step ③ and store it in a refrigerator at 5°C for later use;

[0031] 2. Wet primary mixing of acetylated modified dissolving pulp / PP...

Embodiment 2

[0040] Prepare the modified CNF / HDPE composite material according to the following method, the steps are as follows:

[0041] 1. acetylation modification of NBKP

[0042] Accurately weigh 10g of bleached softwood kraft pulp (NBKP) that has been decomposed and dried at room temperature to constant weight, put it in a round bottom flask equipped with a condensing reflux device, add 100ml of glacial acetic acid, 0.5g of concentrated sulfuric acid and 9.5g of acetic anhydride , Reaction at 50°C for 1h. After the reaction, centrifuge and wash repeatedly at 5000r / min until the supernatant is neutral. The moisture content of the product was measured and stored in a 5°C refrigerator for later use.

[0043] 2. Wet primary mixing of acetylated modified NBKP / HDPE composites

[0044]Accurately weigh 1.5g of acetylated modified NBKP in step (1), adjust the slurry concentration to 2%, then add 40g of high-density polyethylene powder, 1.2g of maleic anhydride grafted polyethylene powder, ...

Embodiment 3

[0048] Prepare the modified CNF / PA6 composite material according to the following method, the steps are as follows:

[0049] 1. Acetylation modification of dissolving pulp

[0050] Accurately weigh 10g of dissolving slurry that has been decomposed and dried at room temperature to constant weight, place it in a round bottom flask equipped with a condensing reflux device, add 100ml of glacial acetic acid, 0.5g of concentrated sulfuric acid and 9.5g of acetic anhydride, and react at 50°C for 1h. After the reaction, centrifuge and wash repeatedly at 5000r / min until the supernatant is neutral. The moisture content of the product was measured and stored in a 5°C refrigerator for later use.

[0051] 2. Wet primary mixing of acetylated modified dissolving pulp / PA composite material

[0052] Accurately weigh 1.5g of the acetylated modified dissolving slurry in step (1), adjust the slurry concentration to 1.5%, then add 40g of nylon 6, 0.8g of silane coupling agent KH560, magnetically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com