Clean air separation gas combustion reactor system and operation method

A reactor system, a gas combustion technology, applied in the combustion method, combustion air/fuel supply, combustion equipment, etc., can solve the problems of resource waste, single oxygen source, large fluctuation of flue gas circulation, etc., to save energy, The effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

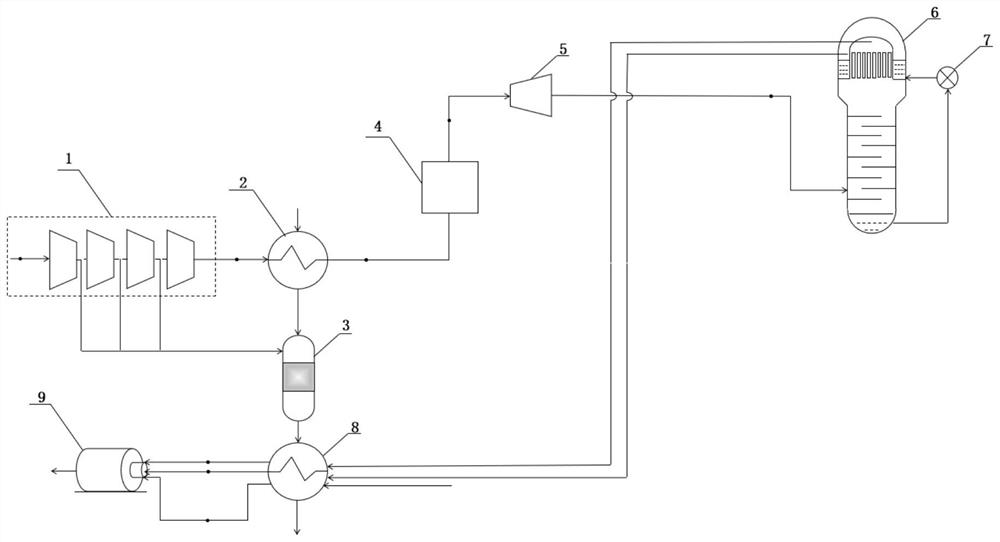

[0037] Such as figure 1 As shown, a clean air separation gas combustion reactor system of the present invention consists of a compression device 1, an end cooler 2, a heat storage tank 3, a cold box 4, a cryogenic expander 5, a fractionation tower 6, and a throttle valve 7. Composed of reheater 8 and natural gas boiler 9;

[0038] The outlet of the last stage of the compression device 1 communicates with the inlet of the hot end of the final cooler 2, the outlet of the hot end of the final cooler 2 communicates with the inlet of the cold box 4, the outlet of the cold box 4 communicates with the inlet of the cryogenic expander 5, and the deep The outlet of the cold expander 5 communicates with the inlet of the lower tower still of the fractionating tower 6, and then the tower bottom outlet of the fractionating tower 6 communicates with the reflux liquid inlet of the upper part of the fractionating tower 6 through the throttle valve 7, and the condensing evaporator in the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com