Lead frame, lead frame single-side brown oxidation process and semiconductor packaging body

A technology of brown oxidation and lead frame, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of affecting the integrity of semiconductor packages, high-pressure water washing or polishing processes, and increasing packaging costs, etc. problems, to achieve the effect of improving resource utilization, cleaning difficulty is small, and increasing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

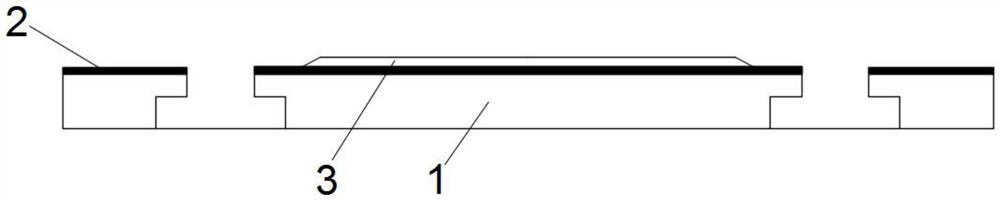

[0034] A lead frame such as figure 1 As shown, a layer of brown oxide layer 2 is provided on the upper surface of the substrate 1, and the electroplated surface of the bonding area of the substrate 1 is on the brown oxide layer 2, and in the bonding area from top to bottom are electroplated layer 3, brown oxide layer Layer 2 and Substrate 1.

[0035] In some examples, the size of the lead frame is 5*5mm.

Embodiment 2

[0037] Provide lead frame single-sided brown oxidation process, provide roll-type base material, the base material is made of copper alloy with pure copper accounting for more than 97%, including the following steps:

[0038] S1. Cleaning, also known as pre-cleaning. The cleaning step includes degreasing and drying processes. The temperature of degreasing is 55°C, the positive and negative difference of temperature is within 5°C, and the pressure of degreasing spray is 5-25psi, preferably 15psi , after the degreasing is completed, the substrate is dried;

[0039] S2, single-sided brown oxidation, undertake the substrate after cleaning in the previous step, firstly paste dry film on the back of the target brown oxidation surface on the substrate, the dry film adopts electroplating dry film, and the surface of the dry film retains PET Film, the back of the target brown oxidized surface is used as the back of the lead frame, the target brown oxidized surface on the substrate is u...

Embodiment 3

[0050] In the cleaning process of step S1 in this embodiment, degreasing refers to using alkali to clean the anti-oxidation oil layer on the copper surface to prevent its oxidation, and at the same time remove oxides and foreign matter on the substrate to protect the subsequent dry film application process from The deformation of foreign matter affects the quality of brown oxidation; the difference from Example 1 is that after alkali cleaning, the base material is slightly etched with acid to produce a rough surface on the base material, ensuring that the subsequent dry film will be more bonded to the copper surface. Tight, no peeling phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com