Preparation method of flexible self-supporting Li3VO4/C nanofiber lithium ion battery negative electrode material

A technology of lithium ion battery and negative electrode material, applied in the field of electrochemical power supply, can solve the problems of low electronic conductivity and ionic conductivity of negative electrode material, large polarization, poor electrochemical reaction kinetics, etc. The effect of high capacity, excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

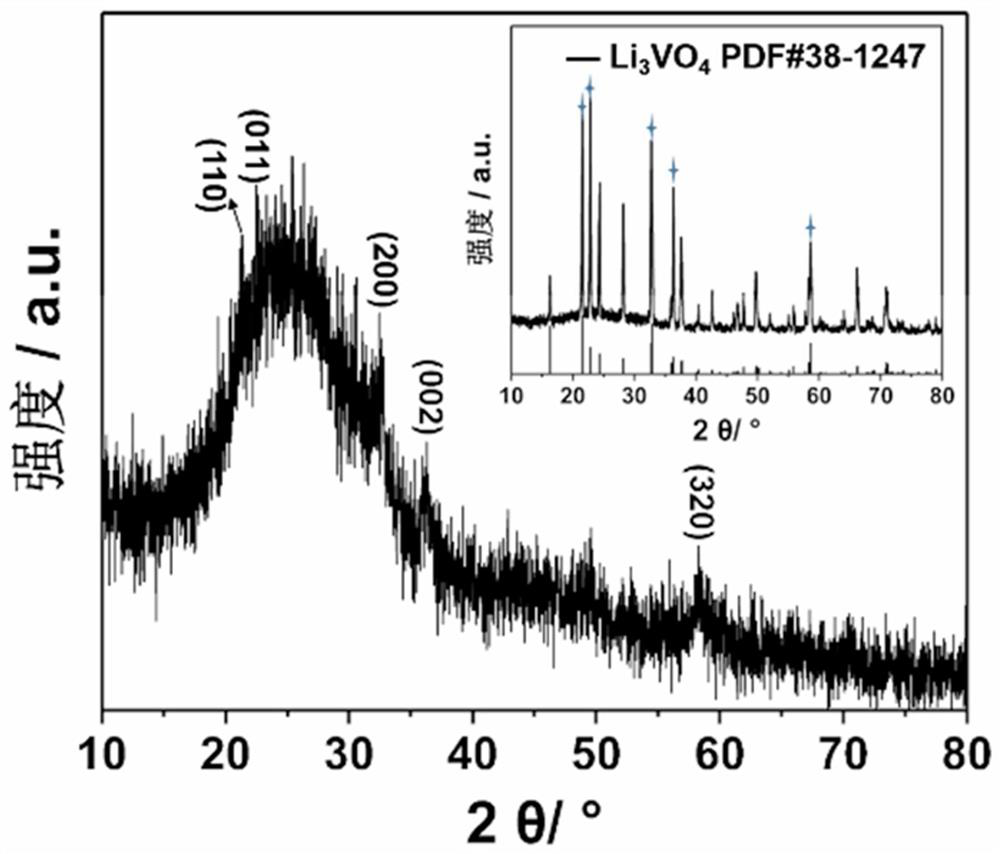

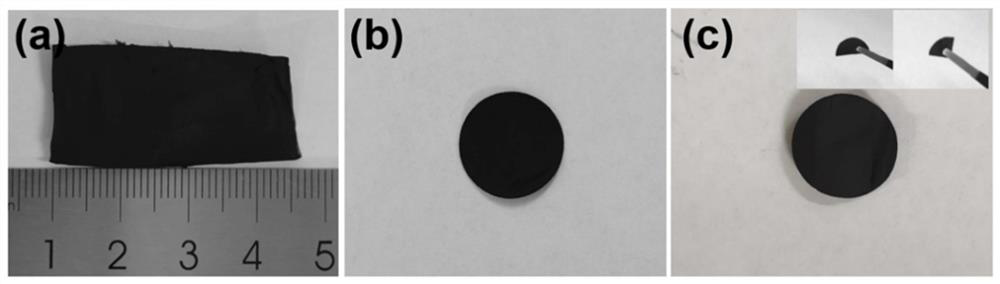

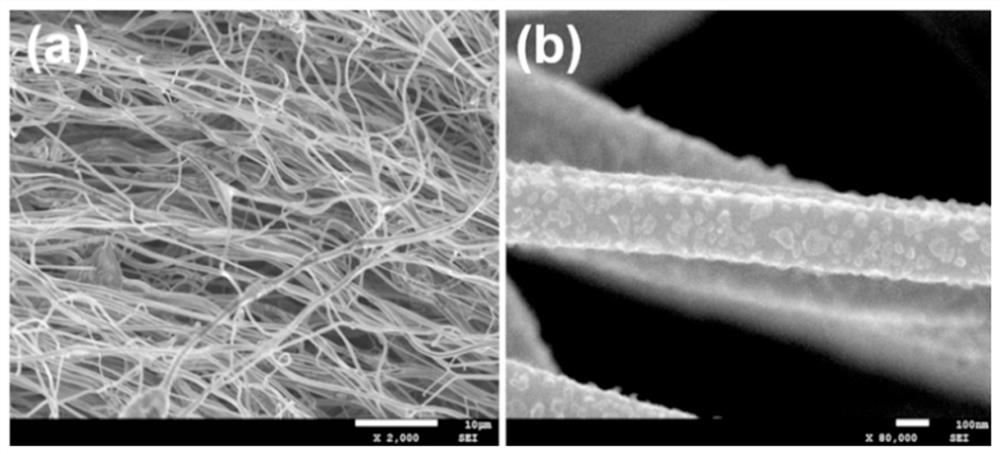

[0025]Accurately weigh 3.75 mmol of lithium nitrate, 3.75 mmol of oxalic acid, and 1.25 mmol of ammonium metavanadate according to stoichiometry, add them to 5 mL of N,N-dimethylformamide and stir in a water bath at a constant temperature of 60°C for 1 hour to obtain a uniform blue color Solution A; at the same time, take 0.65 g of polyacrylonitrile and add it to 5 mL N,N-dimethylformamide and stir for 30 minutes until a colorless and transparent solution is formed as solution B, then slowly drop solution A into solution B and stir for 12 hours to obtain a uniform blue electrospinning viscous solution ( Figure 5 a). Then the homogeneous solution obtained was transferred to an electrospinning syringe, and spun at a voltage of 15 kV and a temperature of 40 °C for 8 hours. After spinning, the fiber membrane was quickly transferred to an 80 °C blast drying oven for 12 hours, dried and placed in N 2 In the environment, at a heating rate of 3 °C / min, pre-calcined at 250 °C for 3 ...

Embodiment 2

[0028] The procedure of this example is exactly the same as that of Example 1, except that oxalic acid is not added, and 3.75 mmol of lithium nitrate and 1.25 mmol of ammonium metavanadate are weighed and added to 5 mL of N,N-dimethylformamide and kept in a water bath at a constant temperature of 60°C Stir at low temperature for 1 hour to obtain suspension A; at the same time, take 0.65 g of polyacrylonitrile and add it to 5 mL of N,N-dimethylformamide and stir for 30 minutes until a colorless and transparent solution is formed as solution B, then slowly dissolve solution A Drop in solution B and stir 12 hours, can't obtain homogeneous solution ( Figure 5 b), so electrospinning cannot be performed.

Embodiment 3

[0030] The procedure of this example is exactly the same as that of Example 1, the molar ratio of oxalic acid and ammonium metavanadate is increased to 5:1, and 3.75 mmol of lithium nitrate, 6.25 mmol of oxalic acid, and 1.25 mmol of ammonium metavanadate are added to 5 mL of N, N-dimethylformamide and stirred at a constant temperature of 60°C in a water bath for 1 hour to obtain a uniform green solution A; at the same time, 0.65 g of polyacrylonitrile was added to 5 mL of N,N-dimethylformamide and stirred for 30 minutes to Form a colorless transparent solution as solution B, then slowly drop solution A into solution B and stir for 12 hours to obtain a uniform green electrospinning viscous solution ( Figure 5 c). Then the mixed solution obtained was transferred to an electrospinning syringe, and spun at a voltage of 15 kV and a temperature of 40°C for 8 hours. hours, dried and placed in N 2 In the environment, at a heating rate of 3 °C / min, pre-calcined at 250 °C for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com