Composite lithium battery diaphragm with self-adhesive coating and preparation method thereof

A self-adhesive, lithium-composite technology, applied in the direction of circuits, electrical components, battery components, etc., can solve the problems of battery thermal safety battery charge and discharge performance degradation, reduce the porosity of the composite film and ion transfer efficiency, etc., to achieve enhanced Improvement of storage discharge performance, insulation protection, wettability and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

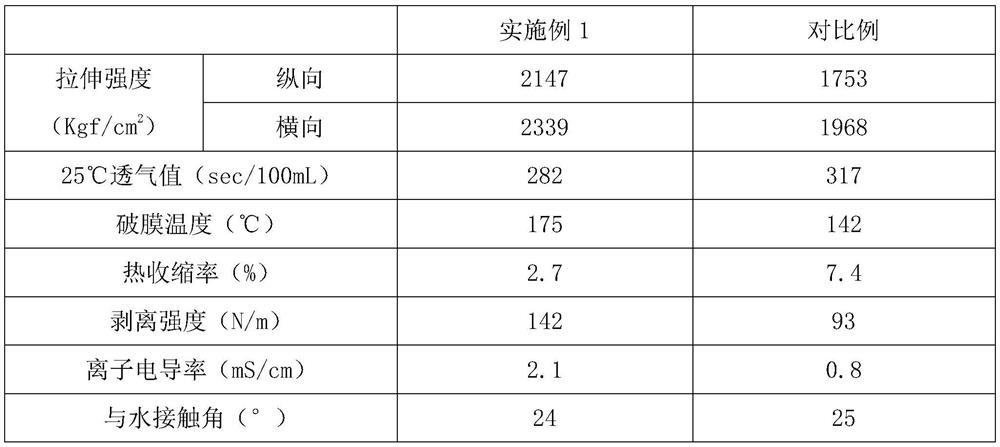

Examples

Embodiment 1

[0037] A composite lithium battery diaphragm with a self-adhesive coating, the composite lithium battery diaphragm is composed of a coating material and a base film; wherein, the base film is a polyolefin microporous film, and the coating material is a self-adhesive organic composite microsphere; The preparation method of sticky organic composite microsphere comprises the following steps:

[0038] Step 1, weigh polyethylene glycol octylphenyl ether and mix it with water, stir until it is completely dissolved, add indium triselenide nanopowder, stir and disperse evenly, import it into a grinding tank for ball milling, and obtain diselenide triselenide Indium mixed liquid; wherein, the mass ratio of polyethylene glycol octylphenyl ether, diindium triselenide nanopowder and water is 1:0.4:2.

[0039] Step 2, preparing diyttrium trioxide / diselenide diindium compound:

[0040] S1. Take diyttrium trioxide and mix it with deionized water, add dropwise ammoniacal liquor to the pH=10....

Embodiment 2

[0051] A composite lithium battery diaphragm with a self-adhesive coating, the composite lithium battery diaphragm is composed of a coating material and a base film; wherein, the base film is a polyolefin microporous film, and the coating material is a self-adhesive organic composite microsphere; The preparation method of sticky organic composite microsphere comprises the following steps:

[0052] Step 1, weigh polyethylene glycol octylphenyl ether and mix it with water, stir until it is completely dissolved, add indium triselenide nanopowder, stir and disperse evenly, import it into a grinding tank for ball milling, and obtain diselenide triselenide Indium mixed liquid; wherein, the mass ratio of polyethylene glycol octylphenyl ether, diindium triselenide nanopowder and water is 1:0.3:1.5.

[0053] Step 2, preparing diyttrium trioxide / diselenide diindium compound:

[0054] S1. Take diyttrium trioxide and mix it with deionized water, add dropwise ammoniacal liquor to the pH=1...

Embodiment 3

[0065] A composite lithium battery diaphragm with a self-adhesive coating, the composite lithium battery diaphragm is composed of a coating material and a base film; wherein, the base film is a polyolefin microporous film, and the coating material is a self-adhesive organic composite microsphere; The preparation method of sticky organic composite microsphere comprises the following steps:

[0066] Step 1, weigh polyethylene glycol octylphenyl ether and mix it with water, stir until it is completely dissolved, add indium triselenide nanopowder, stir and disperse evenly, import it into a grinding tank for ball milling, and obtain diselenide triselenide Indium mixed liquid; wherein, the mass ratio of polyethylene glycol octylphenyl ether, diindium triselenide nanopowder and water is 1:0.5:3.

[0067] Step 2, preparing diyttrium trioxide / diselenide diindium compound:

[0068] S1. Take diyttrium trioxide and mix it with deionized water, add dropwise ammoniacal liquor to the pH=10....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com