Low-density spherical alumina and preparation method thereof

A spherical alumina, low-density technology, applied in the preparation of alumina/hydroxide, chemical instruments and methods, alkali metal oxide/hydroxide, etc., can solve the problems of product purity decline, pore volume is not large, etc. , to achieve the effects of inhibiting high temperature sintering and shrinkage, large pore volume, and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Add 132g of aluminum powder with a particle size of 1-200 μm into 15% dilute hydrochloric acid solution, and prepare refined aluminum sol at 90°C for 3 hours through the magnetic separation continuous refining device provided by Chinese patent CN1746111A. Al in refined aluminum sol 3+ The mass fraction is 12%, and the Al / Cl mass ratio is 0.91.

[0040] (2) Weigh 43.68 g of silica sol with a mass fraction of 30 wt %, add it into the refined aluminum sol obtained in step (1) and stir well to obtain a mixed aluminum sol. At 0°C, 330g of hexamethylenetetramine aqueous solution with a mass fraction of 40% was added to the mixed aluminum sol to obtain the sol to be formed, Al:

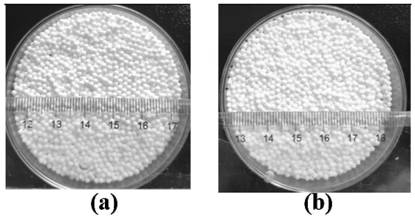

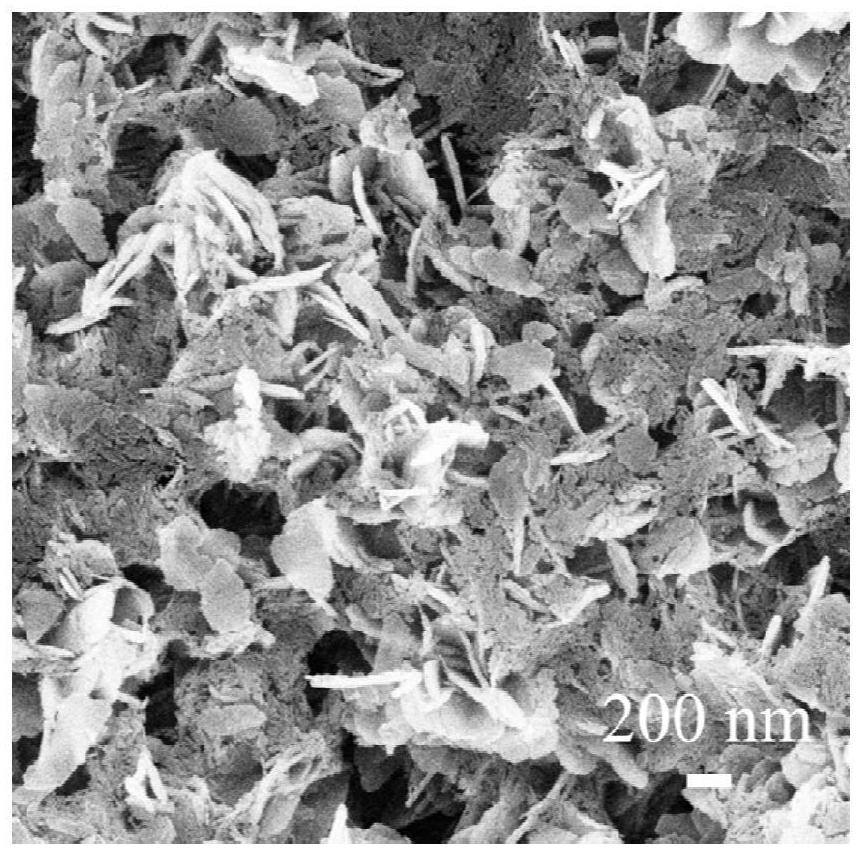

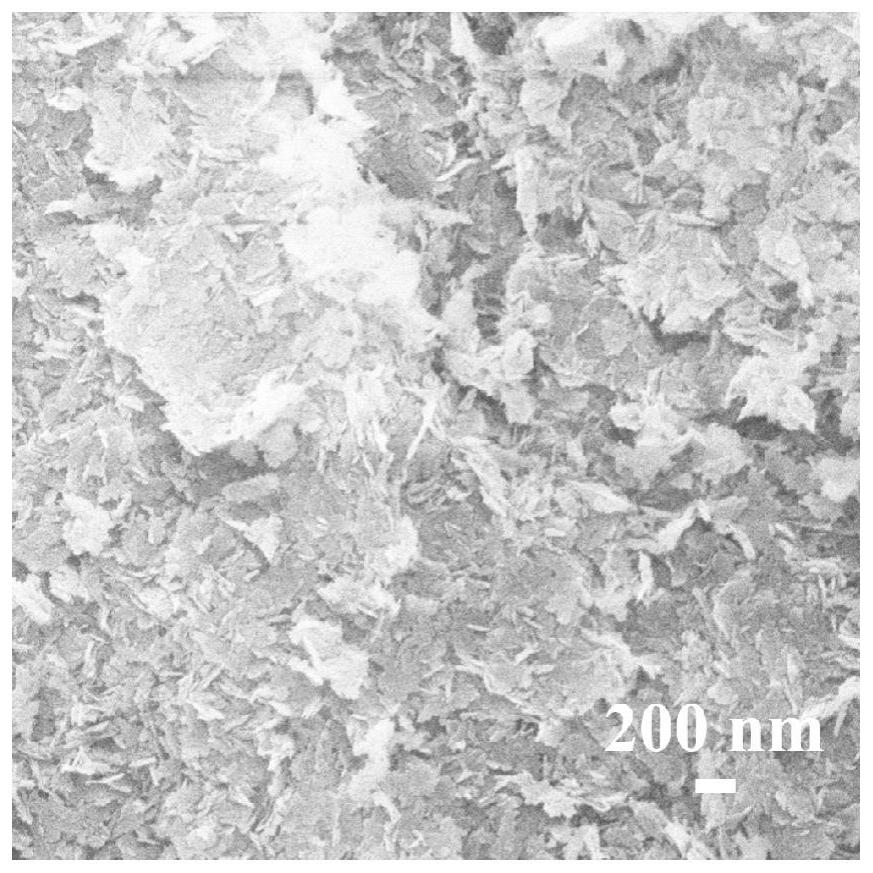

[0041](3) The sol to be formed obtained in step (2) was dropped into hot oil at 90°C through a dispersing needle to form it, and the preliminarily cured pellets were taken out, and aged at 120°C and 0.5 MPa for 10 hours. The aged pellets were washed with deionized water to 1% AgNO 3 Check the...

Embodiment 2

[0043] (1) Add 132g of aluminum powder with a particle size of 1-200 μm to 20% dilute hydrochloric acid solution, and prepare refined aluminum sol at 90° C. for 3 hours through the magnetic separation continuous refining device provided by Chinese patent CN1746111A. Al in refined aluminum sol 3+ The mass fraction is 12%, and the Al / Cl mass ratio is 0.91.

[0044] (2) Add 133.1g of silica sol with a mass fraction of 20% to the fine aluminum sol obtained in step (1) and fully stir to obtain a mixed aluminum sol. At 5°C, 330g of hexamethylene with a mass fraction of 30% The base tetramine aqueous solution is added in the mixed aluminum sol to obtain the sol to be shaped, Al:

[0045] (3) Drop the unmolded sol obtained in step (2) into hot oil at 90°C through a dispersing needle for molding, take out the preliminarily solidified pellets and age at 140°C, 0.6MPa for 8 hours. The aged pellets were washed with deionized water until no visible precipitation was detected in the was...

Embodiment 3

[0047] (1) Add 132g of aluminum powder with a particle size of 1-200 μm to 20% dilute hydrochloric acid solution, and prepare refined aluminum sol at 90° C. for 3 hours through the magnetic separation continuous refining device provided by Chinese patent CN1746111A. Al in refined aluminum sol 3+ The mass fraction is 12%, and the Al / Cl mass ratio is 0.68.

[0048] (2) Weigh 4.4579g of boric acid, add it into the refined aluminum sol obtained in step (1) and stir fully to obtain a mixed aluminum sol. Mix the obtained mixed aluminum sol with 300 g of hexamethylenetetramine solution with a mass fraction of 30% at 5°C to obtain the sol to be formed, Al:

[0049] (3) Drop the unmolded sol obtained in step (2) into hot oil at 90°C through a dispersing needle for molding, take out the preliminarily solidified pellets and age at 150°C, 0.6MPa for 12 hours. The aged pellets were washed with deionized water until no visible precipitation was detected in the washing water with 1% AgNO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com