Preparation method of gold nano-particle aggregate material

A technology of gold nanoparticles and aggregates, applied in the field of nanomaterials, can solve the problems of inability to obtain gold nanoparticle aggregate materials and limit the application of gold nanoparticle aggregate materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

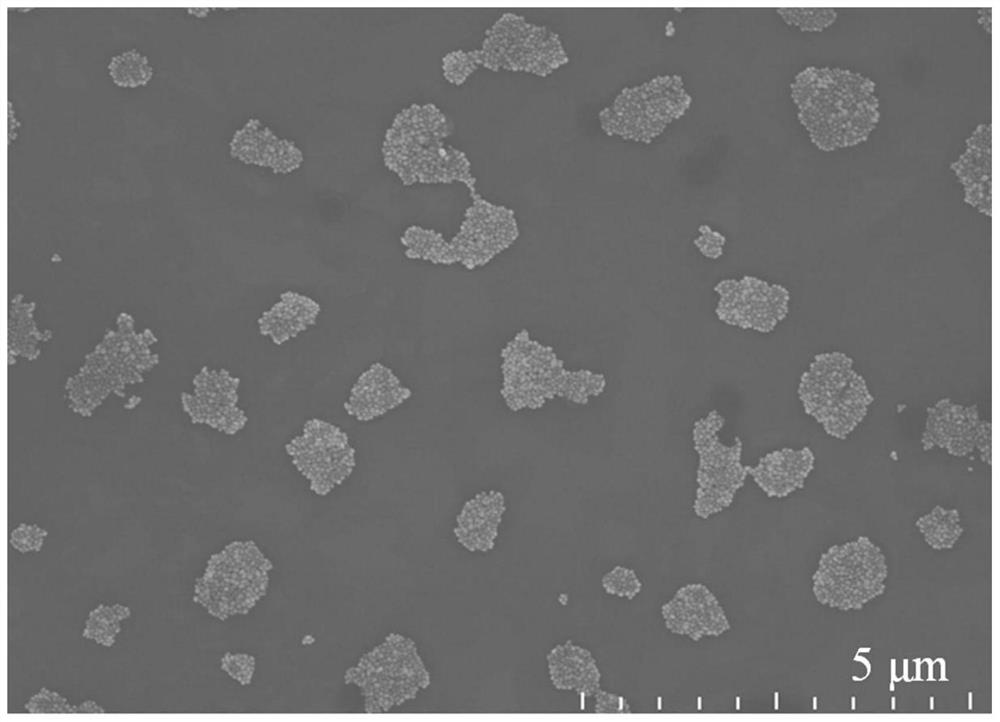

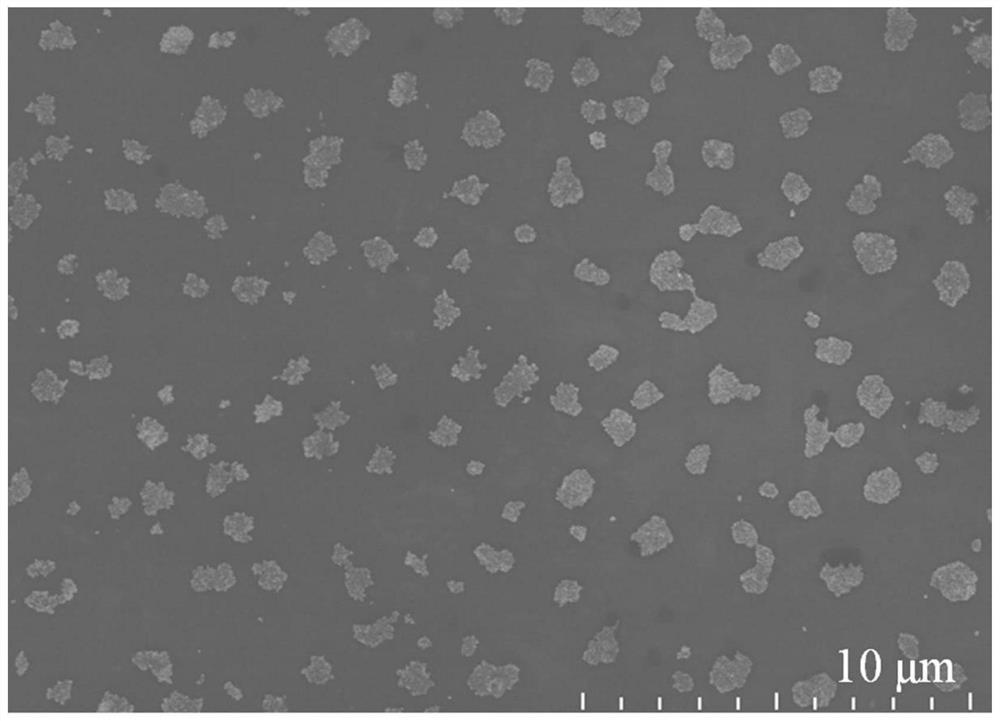

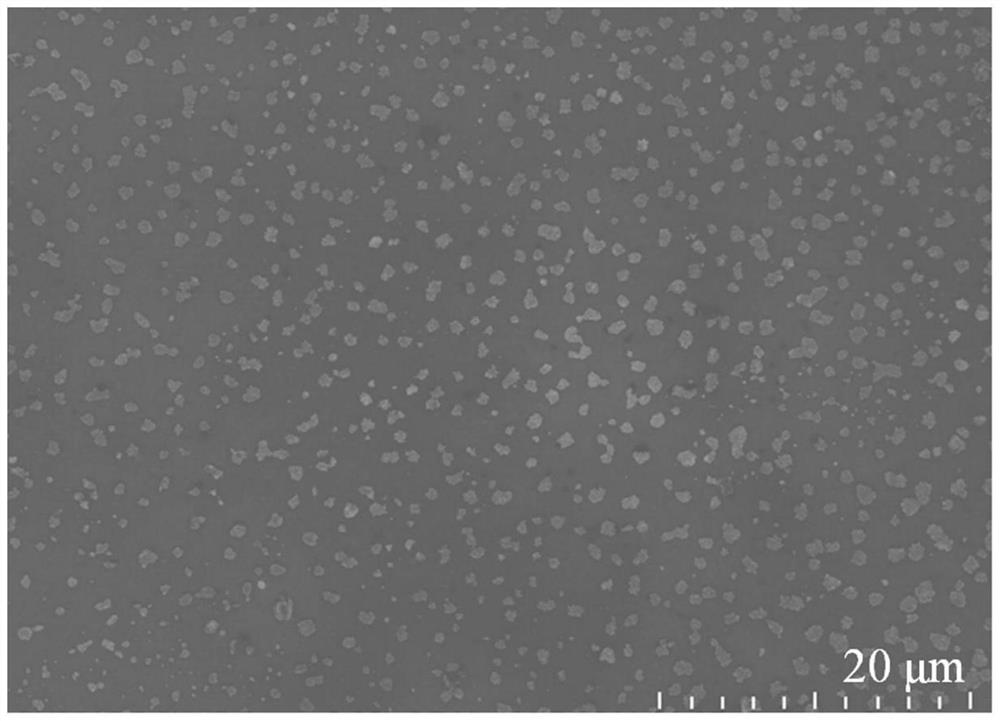

Image

Examples

Embodiment 1

[0021] Step 1: Prepare gold seed solution: first prepare a sodium borohydride solution with a concentration of 0.01M; an aqueous solution of ascorbic acid with a concentration of 0.1M; an aqueous solution of silver nitrate with a concentration of 4mM; an aqueous solution of chloroauric acid with a concentration of 5mM; Cetyltrimethylammonium bromide aqueous solution; concentration of 1.2M hydrochloric acid aqueous solution; concentration of 0.5M sodium hydroxide aqueous solution, after completion, add 0.6 ml of sodium borohydride aqueous solution to 4.5 ml of cetyltrimethylammonium bromide In the mixed solution of ammonium bromide aqueous solution and the chloroauric acid aqueous solution of 0.5 milliliters, form gold seed solution;

[0022] Step 2: Prepare growth solutions A, B, and C: Growth solutions A and B are a mixture of 0.9 milliliters of cetyltrimethylammonium bromide aqueous solution, 0.09 milliliters of chloroauric acid aqueous solution and 0.072 milliliters of ascor...

Embodiment 2

[0026]Step 1: Prepare gold seed solution: first prepare a sodium borohydride solution with a concentration of 0.01M; an aqueous solution of ascorbic acid with a concentration of 0.1M; an aqueous solution of silver nitrate with a concentration of 4mM; an aqueous solution of chloroauric acid with a concentration of 5mM; Cetyltrimethylammonium bromide aqueous solution; concentration of 1.2M hydrochloric acid aqueous solution; concentration of 0.5M sodium hydroxide aqueous solution, after completion, add 0.6 ml of sodium borohydride aqueous solution to 4.5 ml of cetyltrimethylammonium bromide In the mixed solution of ammonium bromide aqueous solution and the chloroauric acid aqueous solution of 0.5 milliliters, form gold seed solution;

[0027] Step 2: Prepare growth solutions A, B, and C: Growth solutions A and B are a mixture of 0.9 milliliters of cetyltrimethylammonium bromide aqueous solution, 0.09 milliliters of chloroauric acid aqueous solution and 0.072 milliliters of ascorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com