Preparation method of alkali-activated fly ash-converted carbon nanotube/leucite porous ceramic composite material

A technology of carbon nanotubes and porous ceramics, which is applied in the field of green preparation technology of waste slag porous materials, and achieves the effects of low density, controllable pores, and simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

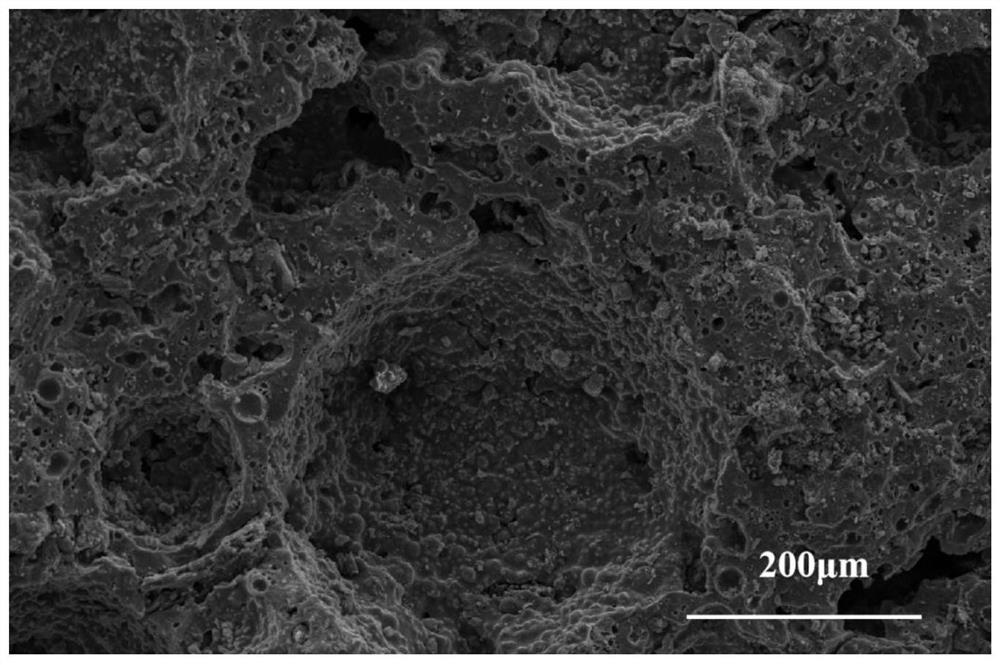

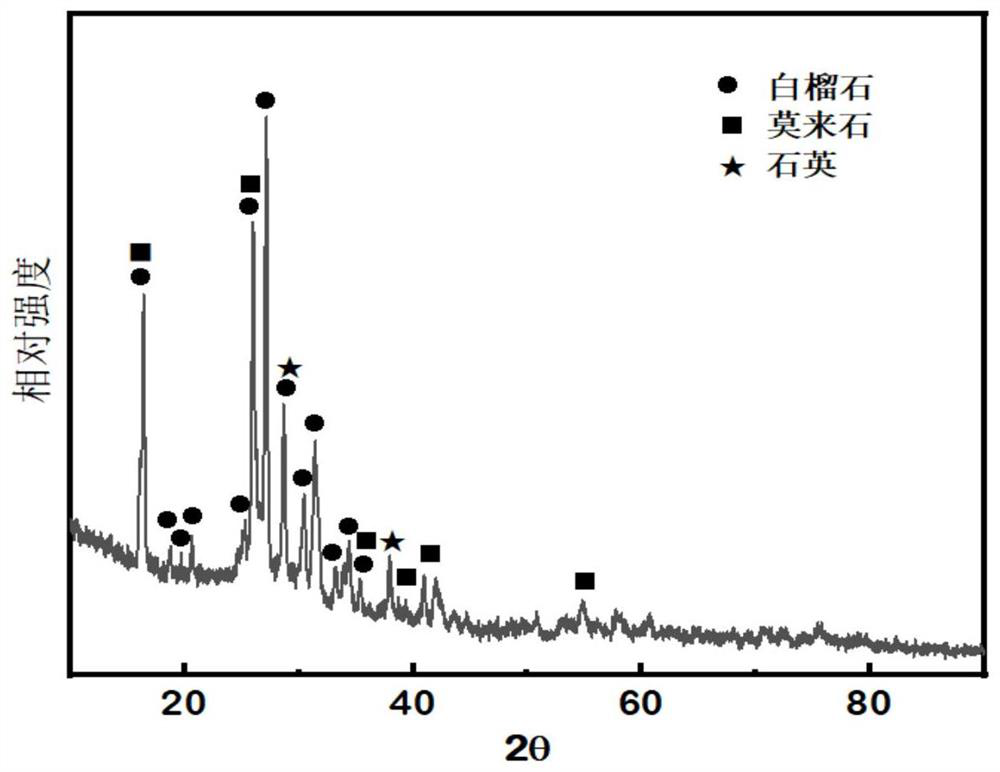

Image

Examples

Embodiment 1

[0027] A method for preparing a carbon nanotube / leucite porous ceramic composite material transformed by alkali-activated fly ash, the steps are as follows:

[0028] Step 1. Pretreatment of raw material fly ash and carbon nanotubes

[0029] Fly ash with a coarse particle size is ground to 1-5 μm, and the multi-walled carbon nanotubes are carboxylated with a sulfuric acid solution so that the surface has carboxyl and hydroxyl functional groups.

[0030] The raw material fly ash is low-calcium fly ash, and its composition is: 53wt% SiO 2 , 37wt% Al 2 o 3 , 3wt% CaO, 3wt% Fe 2 o 3 and 0.3 wt% MgO.

[0031] Step 2. Configure alkaline silica sol excitation solution

[0032] Potassium hydroxide was added to the silica gel solution with a mass fraction of 40% at a molar ratio of 1:1, and stirred with a 1000 rpm magnetic stirrer for 30 min to obtain an alkaline silica sol excitation solution whose main component was potassium silicate.

[0033] Step 3, mixing of carbon nanotube...

Embodiment 2

[0047] The difference from Example 1 is that the mass ratio of carbon nanotubes to the alkaline silica sol excitation solution in step 3 is 1.2:17, and the others are the same as in Example 1.

[0048] The alkali-activated fly ash converted carbon nanotube / leucite porous ceramic composite material obtained in this example has uniform pores and a density of 1.4 g / cm 3 , the compressive strength is 30.2MPa, the total porosity is 40%, and the open porosity is 34%.

Embodiment 3

[0050] The difference from Example 2 is that the mass ratio of the carbon nanotubes to the alkaline silica sol excitation solution in step 3 is 1.35:17; / min rate is cooled to normal temperature, and other is identical with embodiment 2.

[0051] The alkali-activated fly ash converted carbon nanotube / leucite porous ceramic composite material obtained in this example has uniform pores and a density of 1.4 g / cm 3 , the compressive strength is 23.7MPa, the total porosity is 39%, and the open porosity is 34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com