Straw organic fertilizer and preparation method thereof

A straw organic fertilizer and straw technology, applied in the field of straw organic fertilizer and its preparation, can solve the problems of incomplete sterilization of base materials, odor diffusion, nutrient loss, etc., and achieve environmental protection, increase nitrogen content, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

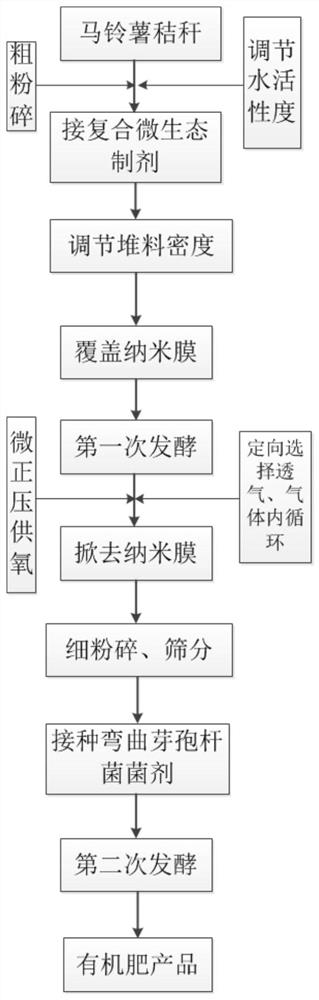

[0062] Such as figure 1 As shown, the present embodiment provides a method for preparing potato stalk organic fertilizer, the steps are as follows:

[0063] 1. Preparation of bacterial agents

[0064] The total effective number of viable bacteria of the composite probiotics used in this embodiment is 1.89×10 9 cfu / g, including the first bacterial agent, the second bacterial agent and the third bacterial agent, the first bacterial agent includes Myceliophthora thermophila and Streptomyces thermophilus, the second bacterial agent includes Thermus thermophilus, thermophilic fat Geobacillus and marine rhodothermophilus, third agent includes defense against Pseudomonas, Geotrichum candidum and Bacillus licheniformis; effective viable counts between first agent, second agent and third agent The ratio is 1:0.83:1.08.

[0065] The effective number of viable bacteria of the Bacillus flexus inoculum that the present embodiment adopts is 1.09×10 10 cfu / ml.

[0066] 2. Preparation o...

Embodiment 2

[0072] This embodiment provides a method for preparing potato stalk organic fertilizer, the steps are as follows:

[0073] 1. Preparation of bacterial agents

[0074] The total effective number of viable bacteria of the composite probiotics used in this embodiment is 2.24×10 9 cfu / g, including the first bacterial agent, the second bacterial agent and the third bacterial agent, the first bacterial agent includes Myceliophthora thermophila and Streptomyces thermophilus, the second bacterial agent includes Thermus thermophilus, thermophilic fat Geobacillus and marine rhodothermophilus, third agent includes defense against Pseudomonas, Geotrichum candidum and Bacillus licheniformis; effective viable counts between first agent, second agent and third agent The ratio is 1:1.01:1.12.

[0075] The effective number of live bacteria of the Bacillus flexus bacterial agent that present embodiment adopts is 1.25 * 10 10 cfu / ml.

[0076] 2. Preparation of potato straw organic fertilizer...

Embodiment 3

[0082] This embodiment provides a method for preparing potato stalk organic fertilizer, the steps are as follows:

[0083] 1. Preparation of bacterial agents

[0084] The total effective number of viable bacteria of the composite probiotics used in this embodiment is 1.68×10 9 cfu / g, including the first bacterial agent, the second bacterial agent and the third bacterial agent, the first bacterial agent includes Myceliophthora thermophila and Streptomyces thermophilus, the second bacterial agent includes Thermus thermophilus, thermophilic fat Geobacillus and marine rhodothermophilus, third agent includes defense against Pseudomonas, Geotrichum candidum and Bacillus licheniformis; effective viable counts between first agent, second agent and third agent The ratio is 1:1.14:0.98.

[0085] The effective number of live bacteria of the Bacillus flexus bacterial agent that present embodiment adopts is 1.25 * 10 10 cfu / ml.

[0086] 2. Preparation of potato straw organic fertilizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com