Method for preparing agricultural water-retaining agent from waste green algae

An agricultural water-retaining agent and water-retaining agent technology, applied in chemical instruments and methods, applications, agriculture, etc., can solve problems such as inability to meet market requirements, and achieve the effects of facilitating use, breaking through seasonal limitations, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

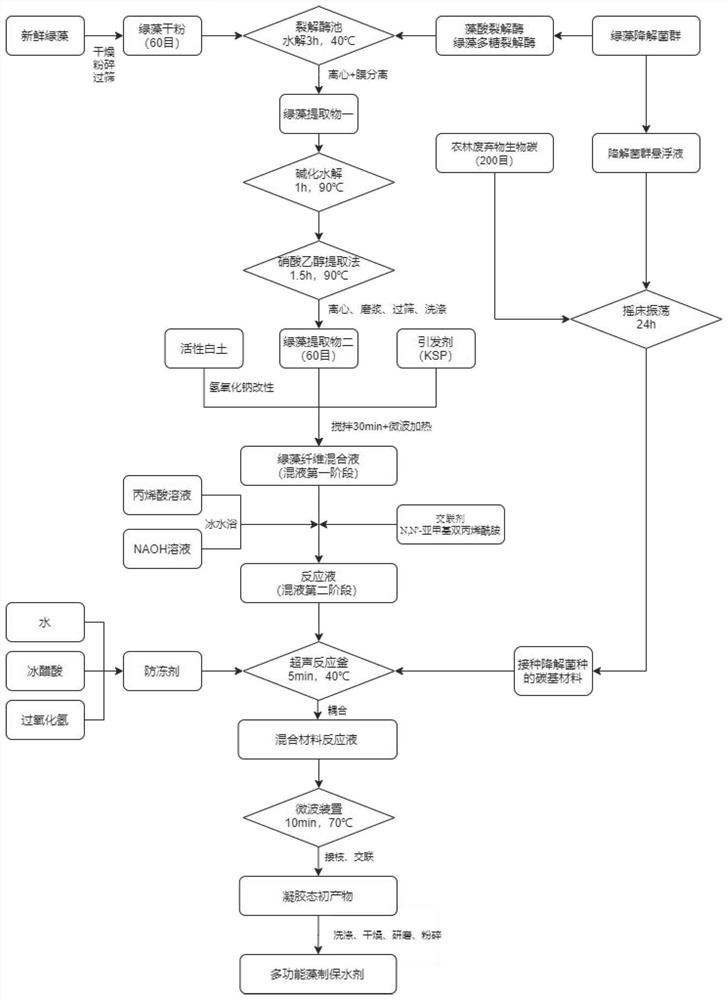

Method used

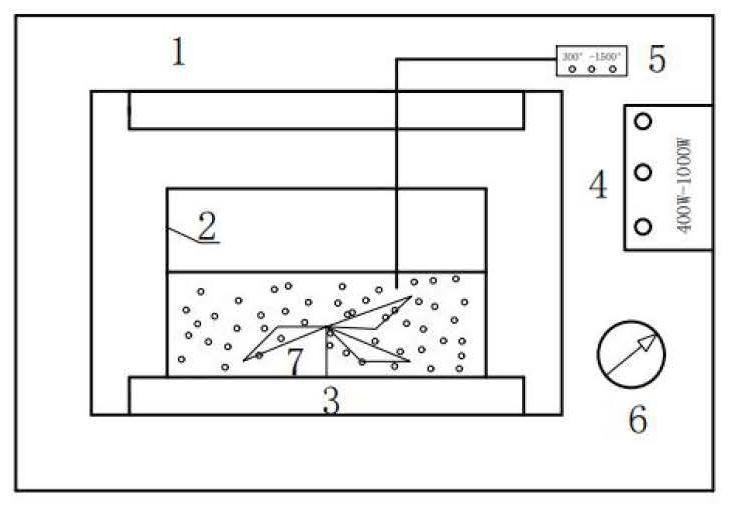

Image

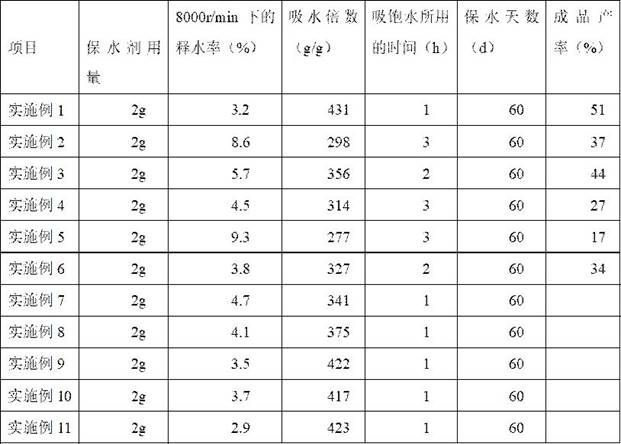

Examples

Embodiment 1

[0041] Select 1kg of fresh green algae, dry it after cleaning, and then crush it with a pulverizer and pass through a 60-mesh sieve to obtain 100g of green algae dry powder; pour 100g of green algae dry powder into the lyase pool (add the feed liquid Water at a ratio of 1:20) for hydrolysis, the lyase used is a mixture of alginate lyase and chlorophyll polysaccharide lyase, the time of enzymolysis is 3 hours, the enzymolysis temperature is 40°C, after centrifugation (the centrifugal speed is 7000r / min, centrifugation time is 10min), membrane separation (the semi-permeable membrane used in membrane separation is ultrafiltration membrane (UF)) to obtain the green algae extract 1; the green algae extract 1 is passed through a 60-mesh sieve, washed, and then used The lye is subjected to alkalization pretreatment, the lye is 10% sodium hydroxide solution, the amount of lye added is 300g, the green algae extract is further hydrolyzed, and after alkali treatment at 90°C for 1 hour, e...

Embodiment 2

[0042] Embodiment 2: (low degree of neutralization)

[0043] A multifunctional integrated agricultural water-retaining agent prepared by extracting green algae cellulose from waste green algae combined with carbon-based materials. The difference from Example 1 is that the neutralization degree of the acrylic acid solution and sodium hydroxide solution is controlled at 60%. .

Embodiment 3

[0044] Example 3: (in neutralization)

[0045] A multifunctional integrated agricultural water-retaining agent prepared by extracting green algae cellulose from waste green algae combined with carbon-based materials. The difference from Example 1 is that the neutralization degree of the acrylic acid solution and sodium hydroxide solution is controlled at 65%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com