Coating composition and Anti-fog member, Anti-fouling member, laminate and Anti-bacterial product using same

A composition and coating technology, applied in synthetic resin layered products, coatings, layered products, etc., can solve problems such as low water resistance, achieve high viscosity stability, reduce environmental load, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0193] The content of water used to complete the preparation of the coating composition is not particularly limited, for example, it is preferably 250 to 9900 parts by mass, more preferably 400 to 3000 parts by mass with respect to 100 parts by mass of the modified polyvinyl alcohol resin (A). . A cured product obtained by cross-linking the polyvinyl alcohol resin (A) in the coating composition while having appropriate viscosity stability in the coating composition by containing water within such a range Favorable binder performance can be imparted to an inorganic particle (B1).

[0194] The application of the coating composition on the base material can use, for example, methods known in the art such as spray coating, roll coating, spin coating, air knife coating, doctor blade coating, brush coating, and dipping. After applying the coating composition, the coating layer containing the uncured binder on the substrate may be dried if necessary.

[0195] In this manner, a pret...

Embodiment I

[0240] (embodiment 1: making and evaluation of antifogging agent)

[0241] (calculation of modification rate)

[0242] The NMR apparatus "LAMBDA 500" manufactured by JEOL Ltd. was used to measure the properties of the modified polyvinyl alcohol resins obtained in Examples I-1 to I-8 or Comparative Examples I-1 and I-2 at room temperature. 1 In H-NMR, the modification rate was calculated from the integrated value of the peak (5.0 to 7.5 ppm) derived from olefin protons. For example, in Example I-1 described later, the modification rate was calculated from the integral values of the peaks derived from olefin protons appearing at 5.6 ppm and 6.0 ppm.

[0243] (Water absorption capacity of cured product of modified polyvinyl alcohol resin (A))

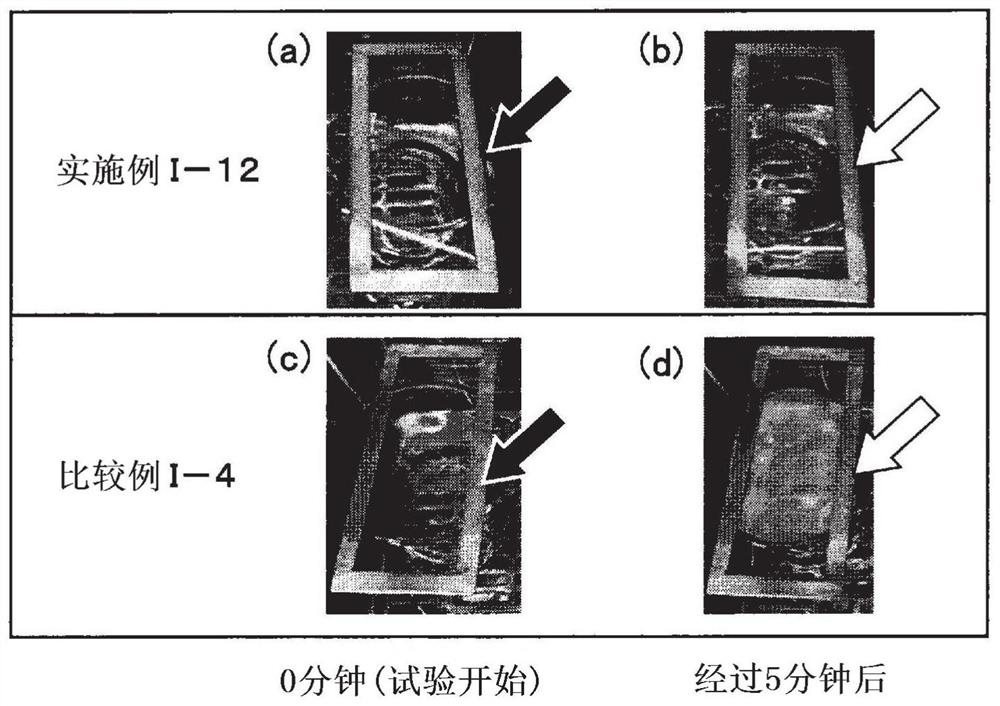

[0244] The antifogging agent stock solution obtained in Examples I-9 to I-17 or Comparative Examples I-3 to I-5 was coated with a bar coater until the corona was applied so that the thickness of the dried coating film reached 20 μm. P...

Embodiment I-1

[0261] (Embodiment I-1: antifogging agent (E i 1) Production)

[0262] 510.3 parts by mass of methacrylic acid, 24.0 parts by mass of acetic acid, 28.4 parts by mass of ion-exchanged water, 1.3 parts by mass of p-methoxyphenol, p-toluenesulfonic acid monohydrate, and 8.1 parts by mass of the product, while stirring at room temperature, add 100 parts by mass of commercially available polyvinyl alcohol resin (number-average degree of polymerization 1700, degree of saponification 95 mol%), and heat up to 65°C under stirring, and react in a slurry state 1 hour. Then cool to room temperature, filter the contents and recover the modified polyvinyl alcohol resin, wash with a large amount of methanol, and dry at 40°C and 1.3Pa for 20 hours, thus obtaining the modified polyvinyl alcohol resin "PVOH i -1". Will get "PVOH i -1" The evaluation results are shown in Table 1. The "PVOH i -1" as an anti-fog agent (E i 1) Used in Examples described later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com