A method for growing large-scale iv-vi compound single crystal thin film materials by pvd technology

An IV-VI, single crystal thin film technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of unrealized large-scale GeSe single crystal thin films, restricted applications, experimental exploration limitations, etc. , to achieve the effect of low experimental cost, less consumables and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

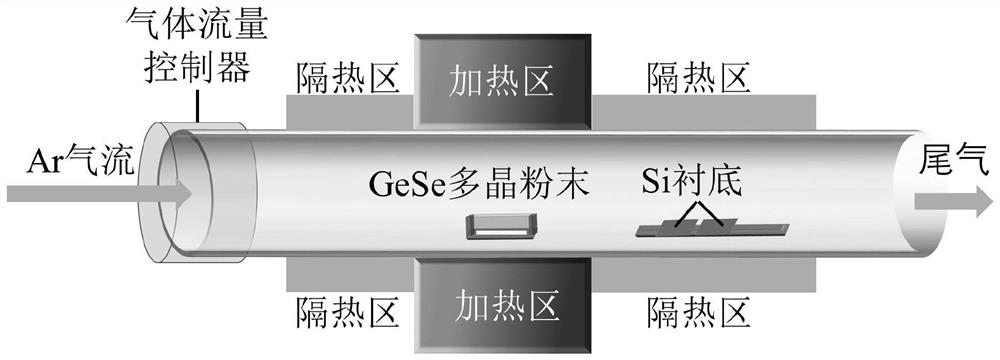

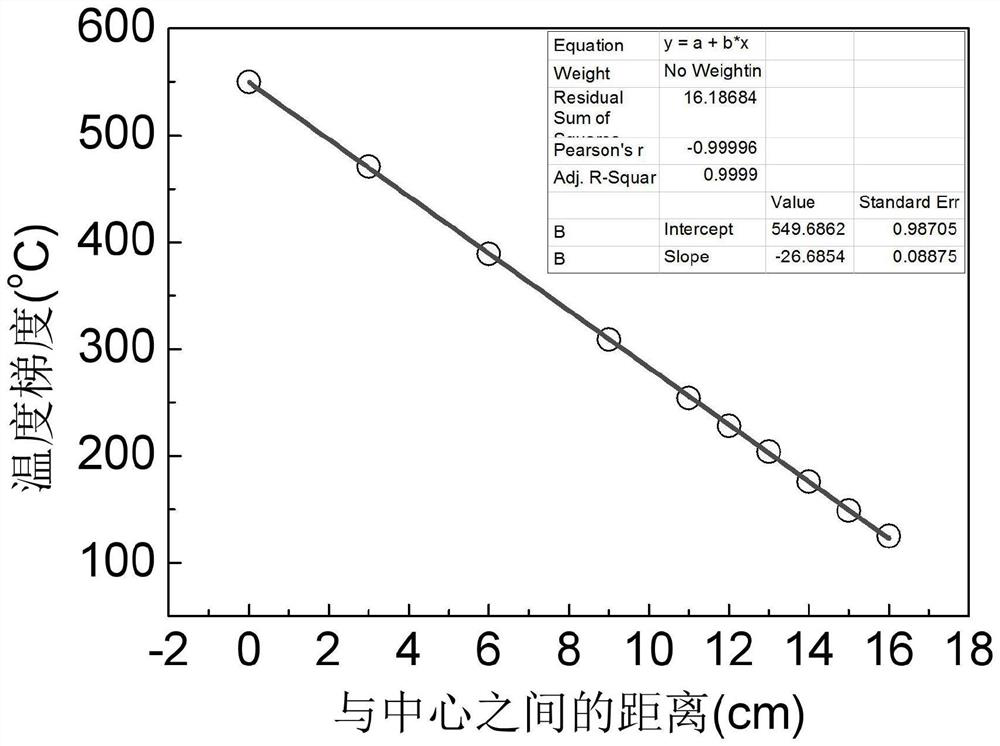

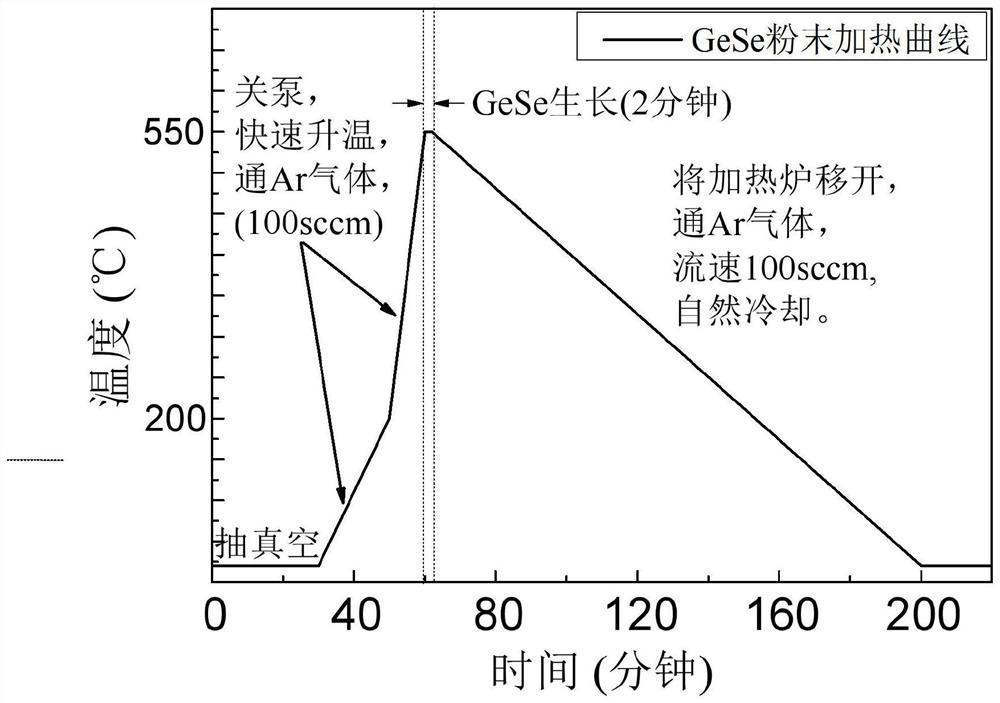

[0037] Embodiment 1 of the present invention provides a method for growing a large-scale GeSe single crystal thin film material by PVD technology. The preparation is carried out in a single heating tube furnace. The specific structure is as follows figure 1 shown; with the increase of the length from the heating center, the change of the temperature gradient at each location is as follows figure 2 The schematic diagram of the temperature and airflow settings during the preparation and growth process is shown in Fig. image 3 shown.

[0038] Specifically include the following steps:

[0039] (1) The substrate selected for the preparation of the sample is a single crystal silicon wafer with surface polishing or a single crystal silicon wafer with surface polishing and oxidation; before preparing the sample, the substrate needs to be cleaned to remove surface impurities; the substrate is immersed in acetone, alcohol, Ultrasonic cleaning in deionized water for 10min respectivel...

Embodiment 2

[0045] The technical solution disclosed in Example 2 of the present invention is basically the same as that in Example 1, except that the high-purity GeSe (99.999%) polycrystalline powder is replaced with high-purity SnS (99.999%) polycrystalline powder.

Embodiment 3

[0047] The technical solution disclosed in Example 3 of the present invention is basically the same as Example 1, except that the high-purity GeSe (99.999%) polycrystalline powder is replaced with high-purity SnSe (99.999%) polycrystalline powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com