Braille printing paper and preparation method and application thereof

A technology of printing paper and braille, applied in special paper, paper, papermaking, etc., can solve the problems of short service life, short life, high strength of printing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

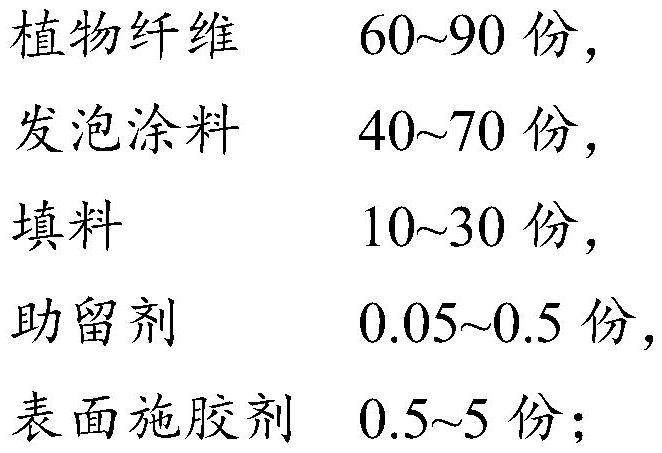

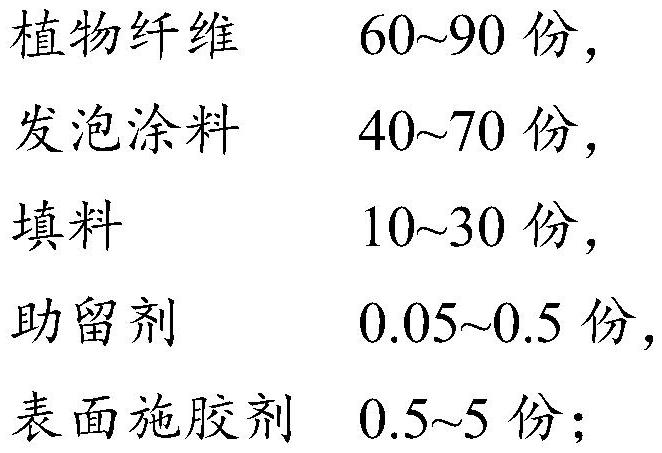

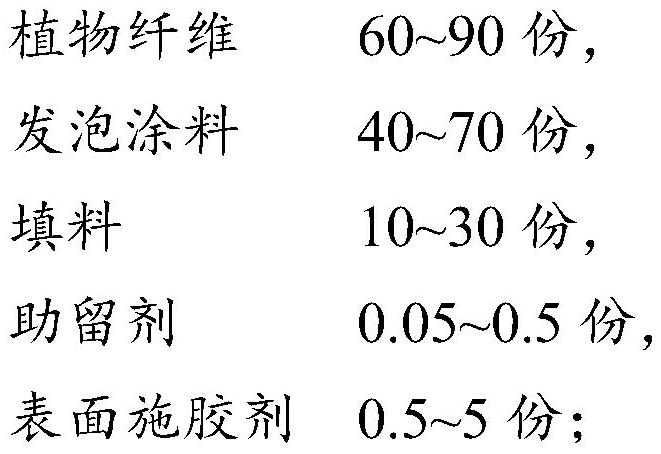

[0047] The present invention also provides a method for preparing braille printing paper described in the above technical solution, comprising the following steps:

[0048] beating the plant fibers, and mixing the obtained pulp with fillers and retention aids in sequence to obtain pulp;

[0049] Paper-making the slurry to obtain unsized raw paper;

[0050] Sizing the unsized raw paper with a surface sizing agent to obtain the sized raw paper;

[0051] The foaming paint is coated on the surface of the sizing paper and dried to obtain the braille printing paper.

[0052] In the present invention, the substances in the preparation method are consistent with the substances in the braille printing paper described in the above technical solution, and will not be repeated here.

[0053] The invention beats the plant fibers, and mixes the obtained pulp with fillers and retention aids in sequence to obtain slurry.

[0054] The present invention has no special limitation on the beati...

Embodiment 1

[0080] Add 60kg of southern pine fibers into a hydropulper for dispersion and transfer to a disc refiner for beating to 28°SR. The resulting pulp is sequentially mixed with 15kg of calcium carbonate and 80kg of polyacrylamide with a concentration of 0.1wt.%, to obtain a slurry;

[0081] The slurry is sent into a paper machine for papermaking to obtain uncoated paper, and the quantitative weight of the uncoated paper is 80g / m 2 ;

[0082] Slowly add oxidized starch into the water, and stir at a constant speed for 30 minutes at 90°C to obtain a surface sizing agent with a mass percentage concentration of 6%, and use the surface sizing agent to carry out in-machine sizing treatment on the unsized raw paper to obtain a sizing agent. Collagen paper, glue amount is 10g / m 2 ;

[0083] The sodium carboxymethyl cellulose of 1kg is mixed with water, obtains the sodium carboxymethyl cellulose solution that the mass percentage concentration is 2.5%, the sodium carboxymethyl cellulose aq...

Embodiment 2

[0087] Put 30kg of southern pine pulp board and 40k poplar chemical pulp into the hydropulper for dispersion, then transfer to the disc refiner for beating to 35°SR, and then mix the obtained pulp with 10kg of kaolin and 60kg of polyacrylamide with a concentration of 0.1wt.%. , get slurry;

[0088] The slurry is sent into a paper machine for papermaking to obtain uncoated paper, and the quantitative weight of the uncoated paper is 80g / m 2 ;

[0089] Slowly add guar gum to the water, and stir at a constant speed for 30 minutes at 60°C to obtain a surface sizing agent with a mass percentage concentration of 1%, and use the surface sizing agent to carry out in-machine sizing treatment on the unsized raw paper to obtain Sizing paper, the amount of glue is 5g / m 2 ;

[0090] 80kg concentration of 8wt.% polyvinyl alcohol aqueous solution and 25kg heat-sensitive foaming microcapsules were placed in a disperser, dispersed at a speed of 3000rpm for 20min to obtain the first mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com