Preparation method of bacitracin zinc

A technology of bacitracin zinc and bacitracin, which is applied in the field of peptide drug preparation, can solve the problems of a large number of crystallization, low yield, unfavorable reaction rate and impurities, etc., and achieves the improvement of crystallization level, product quality, and reduction of product impurity content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

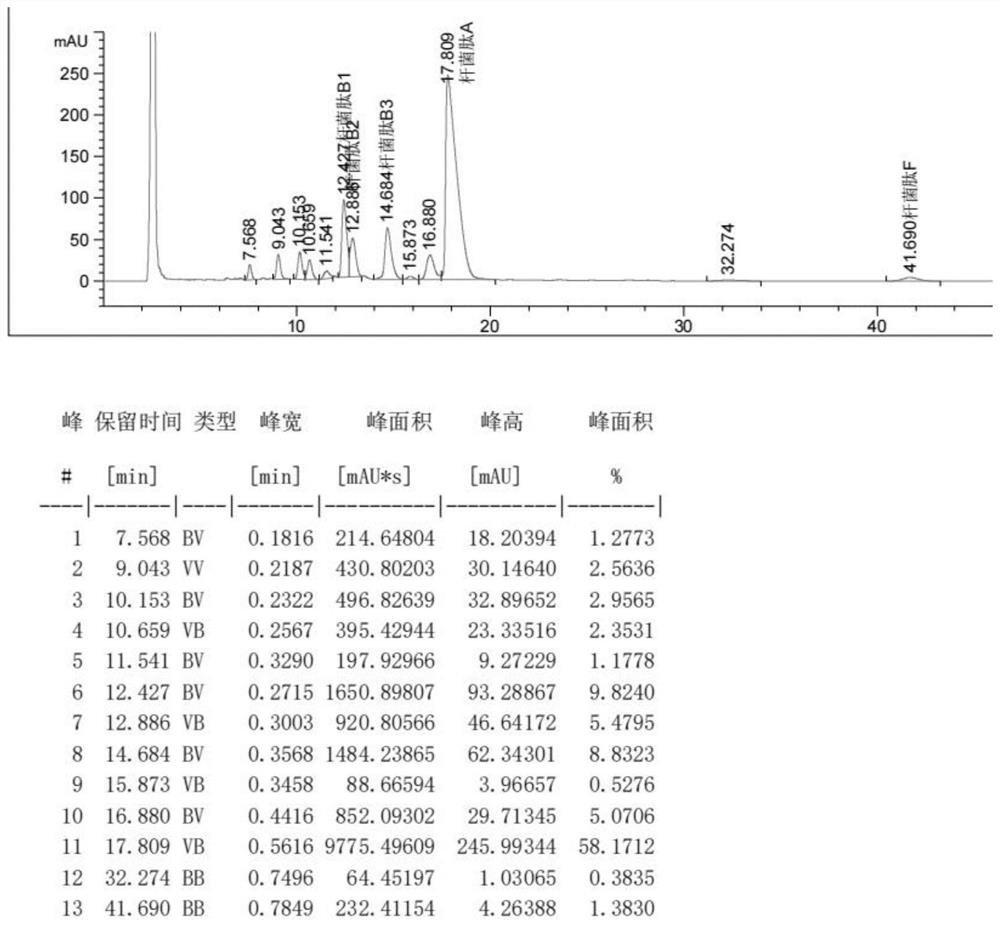

[0029] Take 50 L of secondary bacitracin filtrate (the content of bacitracin is 6400 U / mL), and prepare 10% hydrochloric acid solution to adjust the pH to 6.0. Weigh 500.0 g of zinc chloride, prepare a 30% zinc chloride solution, and add the bacitracin filtrate. After stirring and clarification, 5% sodium hydroxide solution was added to adjust the pH to 6.5. After stirring for 10 minutes, retest the pH to 6.5, and continue stirring for 1 hour. Stop stirring, let it stand for 6 hours, filter with suction, take the filter cake, and dry it for 2 hours at a temperature of 80°C. After receiving the materials, 4.55 kg of white powdery dry product was obtained, and the molar yield was 80.2%. Detected by HPLC (spectrum see figure 1 ), the content of bacitracin A is 58.17%, the total amount of bacitracin A, B1, B2, and B3 is 82.31%, the content of bacitracin F is 1.38%, and the sum of impurities precipitated before bacitracin B1 is 10.33%. Conforms to USP standards. According to U...

Embodiment 2

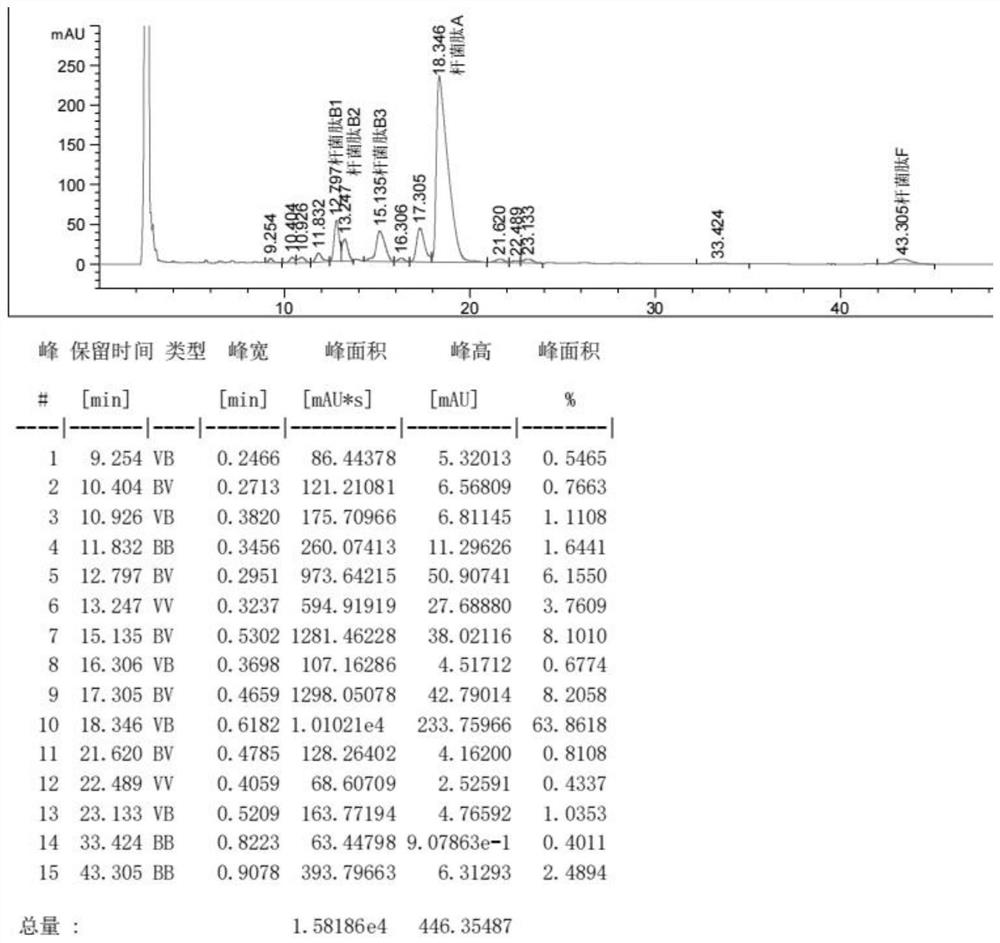

[0031] Take 50L of secondary bacitracin filtrate (bacitracin content is 6400U / mL), prepare 20% hydrochloric acid solution to adjust the pH to 4.0. Weigh 500.0 g of zinc chloride, prepare a 50% zinc chloride solution, and add the bacitracin filtrate. After stirring and clarification, 10% sodium hydroxide solution was added to adjust the pH to 7.5. After stirring for 30 minutes, retest the pH to 7.5, and continue stirring for 1 hour. Stop stirring, let it stand for 6 hours, filter with suction, take the filter cake, and dry it for 4 hours at a temperature of 170°C. After collecting the materials, 4.78 kg of white powdery dry product was obtained, and the molar yield was 84.3%. Detected by HPLC (spectrum see figure 2 ), the content of bacitracin A is 63.86%, the total amount of bacitracin A, B1, B2, and B3 is 81.88%, the content of bacitracin F is 2.49%, and the sum of impurities precipitated before bacitracin B1 is 4.07%. Conforms to USP standards. According to USP standar...

Embodiment 3

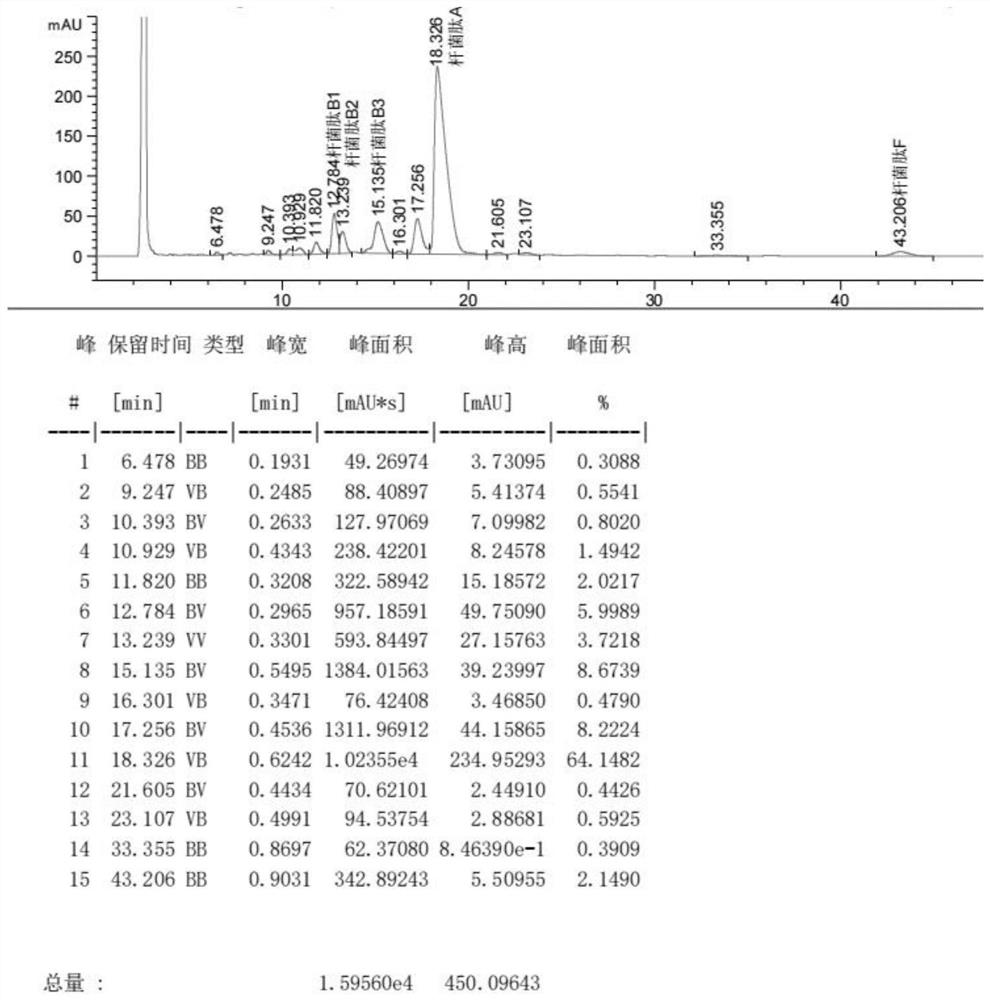

[0033] Take 50L of secondary bacitracin filtrate (the content of bacitracin is 6400U / mL), and prepare 30% hydrochloric acid solution to adjust the pH to 2.5. Weigh 500.0 g of zinc chloride, prepare a 60% zinc chloride solution, and add it to the bacitracin filtrate. After stirring and clarification, 20% sodium hydroxide solution was added to adjust the pH to 8.5. After stirring for 40 minutes, retest the pH to 8.5, and continue stirring for 1 hour. Stop stirring, let it stand for 8 hours, filter with suction, take the filter cake, and dry it for 8 hours at a temperature of 250°C. After receiving the materials, 4.51 kg of white powdery dry product was obtained, and the molar yield was 79.5%. Detected by HPLC (spectrum see image 3 ), the content of bacitracin A is 64.15%, the total amount of bacitracin A, B1, B2, and B3 is 82.54%, the content of bacitracin F is 2.15%, and the sum of impurities precipitated before bacitracin B1 is 5.18%. Conforms to USP standards. According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com