Aqueous dispersion of polyurethane or polyurethane urea, preparation method of aqueous dispersion, aqueous space leather base and preparation method of aqueous space leather base

A technology of polyurethane urea and polyurethane, which is applied in the field of space leather basses, can solve the problems of uneven distribution, less urea group content, and no coupling agent, etc., and achieve the effects of excellent flex resistance, enhanced strength, and improved peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

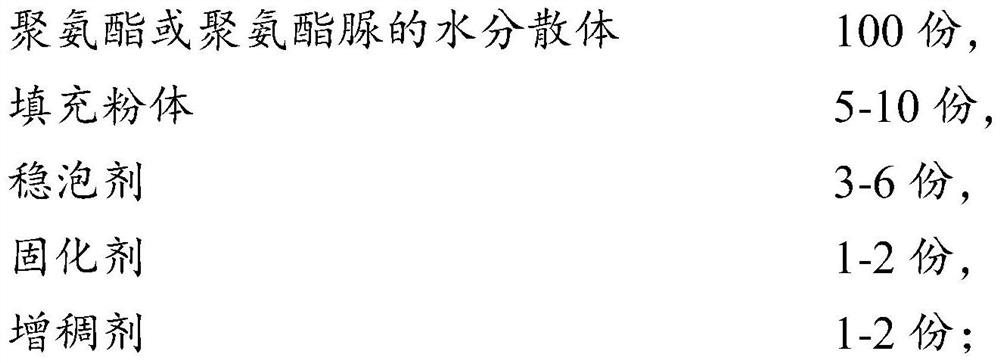

[0111] Preparation of aqueous dispersions of polyurethane or polyurethane urea:

[0112] 1) Add 190g of polytetrahydrofuran ether polyol, 83g of 4,4'-dicyclohexylmethane diisocyanate, 3.5g of DMPA, 2g of Ymer N-120, 0.03g of bismuth neodecanoate and 27.75g of acetone Mix in a four-necked round-bottom flask with a nitrogen inlet and outlet with a volume of 1L for reaction, and react at 60-90°C until the reaction mixture has reached or slightly lower than the theoretical isocyanate content of 5.2%, and the prepolymerization of terminal isocyanate is obtained. thing I;

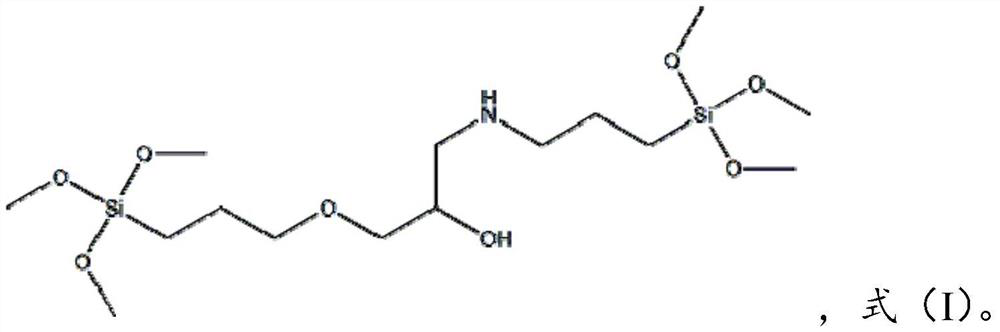

[0113] 2) Cool down the system containing the obtained isocyanate-terminated prepolymer I to 45-50°C, add 9g of [4-(aminomethyl)cyclohexyl]methanol, 5g of 1,11-bis(trimethoxysilyl) )-4-oxo-8-azaundecan-6-ol and 42.36g of acetone were mixed uniformly, and the chain extension reaction was carried out at 60-80°C until the reaction mixture reached or slightly lower than the theoretical isocyanate content of 2.64%. ...

Embodiment 2

[0120] Preparation of aqueous dispersions of polyurethane or polyurethane urea:

[0121]1) Add 262g of polytetrahydrofuran ether polyol, 143g of 4,4'-dicyclohexylmethane diisocyanate, 6.5g of DMPA, 4g of Ymer N-120, 0.1g of bismuth neodecanoate and 42.25g of acetone Mix in a four-neck round-bottomed flask with a volume of 1L equipped with nitrogen inlet and outlet, and react at 60-90°C until the reaction mixture has reached or slightly lower than the theoretical isocyanate content of 6.61%, and the prepolymerization of terminal isocyanate is obtained. thing I;

[0122] 2) Cool down the system containing the obtained isocyanate-terminated prepolymer I to 45-50°C, add 20g of [4-(aminomethyl)cyclohexyl]methanol, 10g of 1,11-bis(trimethoxysilyl) )-4-oxo-8-azaundecan-6-ol and 65.03g of acetone were mixed evenly, and the chain extension reaction was carried out at 60-80°C until the reaction mixture reached or slightly lower than the theoretical isocyanate content of 2.98%. Obtain ...

Embodiment 3

[0129] Preparation of aqueous dispersions of polyurethane or polyurethane urea:

[0130] 1) Add 252g of polytetrahydrofuran ether polyol, 125.6g of 4,4'-dicyclohexylmethane diisocyanate, 5g of DMPA, 4g of Ymer N-120, 0.03g of bismuth neodecanoate and 39.4g of acetone Mix in a four-neck round-bottomed flask with a volume of 1L equipped with nitrogen inlet and outlet, and react at 60-90°C until the reaction mixture has reached or slightly lower than the theoretical isocyanate content of 6.12%, and the prepolymerization of terminal isocyanate is obtained. thing I;

[0131] 2) Cool down the system containing the obtained isocyanate-terminated prepolymer I to 45-50°C, add 16g of [4-(aminomethyl)cyclohexyl]methanol, 8g of 1,11-bis(trimethoxysilyl) )-4-oxo-8-azaundecan-6-ol and 60.6g of acetone were mixed evenly, and the chain extension reaction was carried out at 60-80°C until the reaction mixture reached or slightly lower than the theoretical isocyanate content of 2.95%. Obtain i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com