Smelting alloy component control system and control method

An alloy composition and control system technology, applied in the field of steelmaking and smelting, can solve the problems of not considering the process characteristics of phosphorus recovery and sulfur recovery, inability to adapt to the cost reduction of alloys, and excessive use of alloys, so as to improve resource utilization and facilitate optimization. Parameters, the effect of reducing the cost of steel alloy per ton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

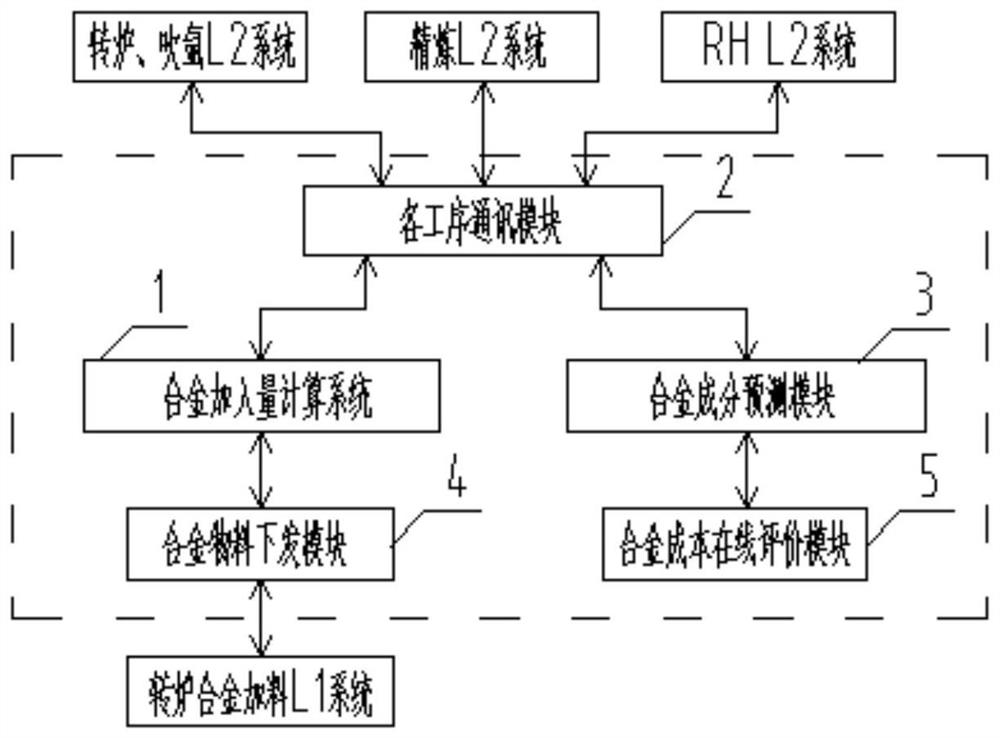

[0104] Embodiment 1: see figure 1, provides a smelting alloy composition control system, the control system includes an alloy addition amount calculation system 1, each process communication module 2, an alloy composition prediction module 3, an alloy material distribution module 4, and an alloy cost online evaluation module 5. The calculation system 1 for alloy addition mainly includes a data processing module and an alloy calculation module. The function of the data processing module is to carry out corresponding logic processing and judgment on the input data such as relevant parameters, smelting route, blowing and stopping composition requirements, deoxidation mechanism, etc.; the alloy calculation module is to realize the automatic calculation of the alloy addition amount including each process of steelmaking. The communication module 2 of each process uses the TCP-based Socket communication interface to realize the sending and receiving of data. The main function is to ...

Embodiment 2

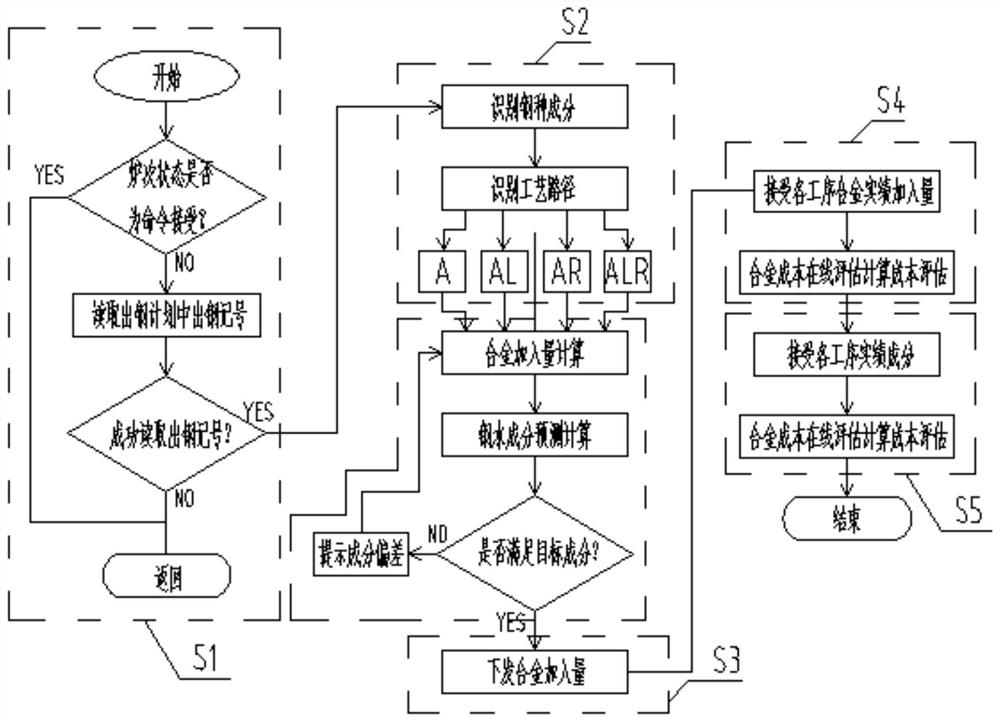

[0105] Example 2: see figure 1 , figure 2 , a method for controlling alloy composition based on the optimal cost of the whole process, said control method comprising the steps of:

[0106] Step 1: Each communication module of the control system obtains the latest tapping plan, manufacturing standard, and operating standard in the L2 process control system, and the actual performance end point sample information of each process and other related data, mainly including obtaining smelting route, plan number, and tapping mark , the upper and lower limits of the composition of the finished product, etc.;

[0107] The specific process is as follows: 1. The L2 system monitoring program of each process monitors system events; 2. After the furnace starts, send the "heating start" event information; 3. After receiving the event, the monitoring program obtains information such as steel types and standards, and communicates with The heat binding of the newly generated heat; 4. Call th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com