Method for preparing anticoagulant coating and medical implant

An anticoagulant and implant technology, applied in the field of medical devices, can solve the problems of poor controllability, complicated operation, poor coating durability, etc., and achieve the effect of good durability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

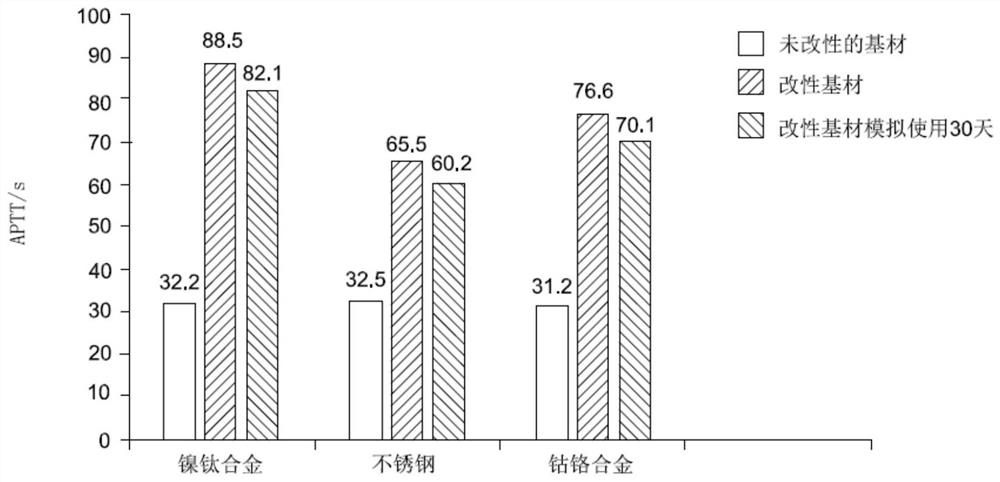

Embodiment 1

[0045] In this embodiment, the substrate is a nickel-titanium alloy sheet of 5 cm×5 cm×0.6 mm.

[0046] The method for forming the anticoagulant coating on the surface of the substrate comprises the following steps:

[0047] First, the substrate was ultrasonically cleaned in ultrapure water for 10 minutes, and then taken out and dried.

[0048] Next, the substrate was immersed in a 5% 3-mercaptopropyltriethoxysilane solution in isopropanol to react for 2 hours, taken out for cleaning, and dried.

[0049] Next, immerse the substrate with mercapto groups introduced into its surface in an oxidative solution for oxidation reaction for 1 h, so as to introduce sulfonic acid groups on the surface of the substrate, take it out and wash it with ultrapure water. The oxidizing solution is formed by mixing methanol, 30% hydrogen peroxide aqueous solution and concentrated sulfuric acid, wherein the volume fraction of methanol is 19.95%, the volume fraction of hydrogen peroxide solution is...

Embodiment 2

[0054] In this embodiment, the substrate is a stainless steel sheet of 8 cm×8 cm×0.5 mm.

[0055] The method for forming the anticoagulant coating on the surface of the substrate comprises the following steps:

[0056] First, the substrate was ultrasonically cleaned in ultrapure water for 10 minutes, and then taken out and dried.

[0057] Next, the substrate was immersed in a methanol solution of 1% 3-mercaptopropyltrimethoxysilane to react for 3 hours, taken out, cleaned and dried.

[0058] Next, immerse the substrate with mercapto groups introduced into its surface in an oxidative solution for oxidation reaction for 30 minutes to introduce sulfonic acid groups on the surface of the substrate, take it out and wash it with ultrapure water. The oxidizing solution is formed by mixing methanol, 30% hydrogen peroxide aqueous solution and concentrated sulfuric acid, wherein the volume fraction of methanol is 50%, the volume fraction of hydrogen peroxide solution is 49.95%, and the...

Embodiment 3

[0063] In this embodiment, the substrate is a cobalt-chromium alloy sheet of 6 cm×6 cm×0.6 mm.

[0064] The method for forming the anticoagulant coating on the surface of the substrate comprises the following steps:

[0065] First, the substrate was ultrasonically cleaned in ultrapure water for 10 minutes, and then taken out and dried.

[0066] Next, the substrate was immersed in an ethanol solution with a mass fraction of 10% of 3-mercaptopropyltriethoxysilane to react for 1.5 hours, taken out, cleaned and dried.

[0067] Next, immerse the substrate with mercapto groups introduced into its surface in an oxidative solution for oxidation reaction for 1 h, so as to introduce sulfonic acid groups on the surface of the substrate, take it out and wash it with ultrapure water. The oxidizing solution is formed by mixing methanol, 30% hydrogen peroxide aqueous solution and concentrated sulfuric acid, wherein the volume fraction of methanol is 49.99%, the volume fraction of hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com