Silicon-carbon composite material for secondary lithium battery and preparation method thereof

A technology of silicon-carbon composite materials and secondary lithium batteries, which is applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of unrealized and high technical barriers, and achieve the goal of improving material performance, improving cycle performance, and reducing new surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method provided by the present invention includes the following steps: a precursor step, a first coating layer coating step, a pre-lithiation step, and a second coating layer coating step;

[0031] The precursor process refers to chemical vapor deposition of silicon raw materials to obtain SiO x (0<x<2) precursor;

[0032] The first cladding layer cladding process refers to the SiO by chemical vapor deposition x Precursor or lithium-doped active particles are coated with conductive layer;

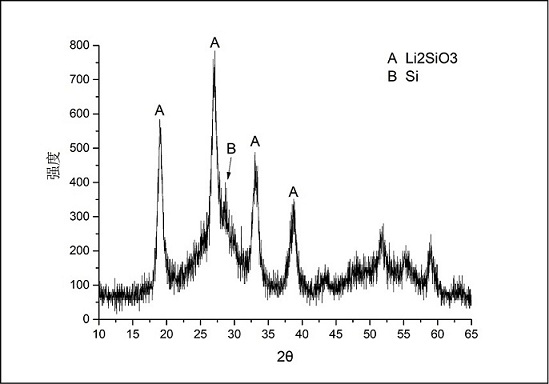

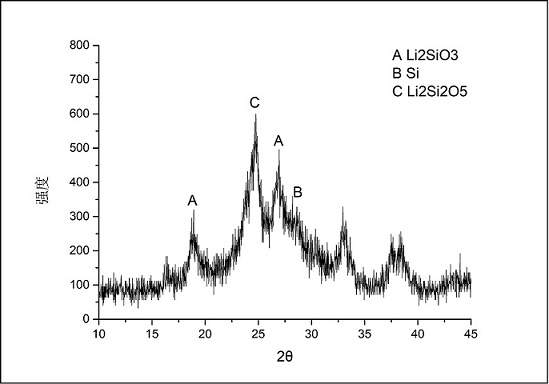

[0033] The pre-lithiation process refers to inserting lithium into the aforementioned coated material to generate lithium silicate inside the silicon oxide compound to obtain lithium-doped active particles;

[0034] The second coating layer coating process refers to SiO x The precursor or lithium-doped active particles are mixed with the ion-enhanced phase and the ion matrix, and evenly dispersed in pure water, and then the mixed solution is filtered and dried to c...

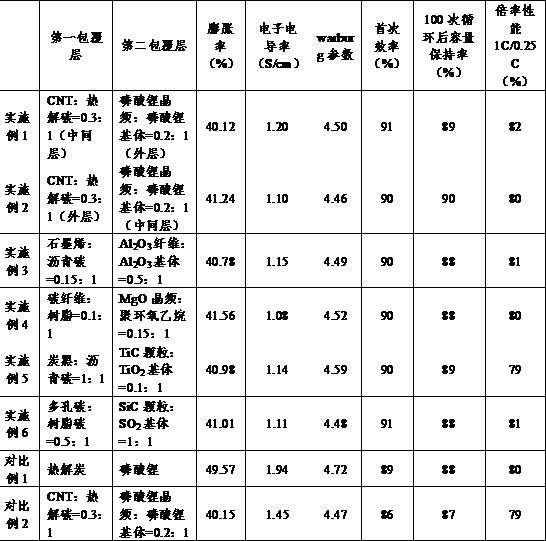

Embodiment 1

[0043] A certain amount of Si powder and SiO 2 Mix the powder evenly, put it into a vacuum furnace for heat treatment, and heat it to 1200°C under the condition of 500Pa vacuum degree, and the heat treatment time is 1h. 1~10um silicon oxide precursor particles.

[0044] Evenly disperse the particles obtained above into pure water, then add 1% CNT (carbon nanotubes) by mass fraction, continue to stir evenly, filter and dry to obtain silicon sub-silicon particles with CNT attached to the surface, and then the particles obtained in the previous step Load it into a CVD furnace, heat it to 950°C, and feed acetylene with a flow rate of 9L / min, hydrogen gas with a flow rate of 9L / min and argon gas with a flow rate of 18L / min, and the deposition time is 1h. Acetylene is decomposed at high temperature to form pyrolytic carbon coated on the surface of CNT and particles to obtain the first coating layer. The cladding layer is a carbon composite material, wherein CNT is a reinforcing ph...

Embodiment 2

[0048] Follow the same method as in Preparation Example 1, except that the ion-conducting layer (second coating layer) is coated first, and then the conductive layer (first coating layer) is coated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com