Method for treating organic silicon low-boiling-point substance by utilizing reactive distillation

A technology for reactive distillation and low boilers, applied in the field of organosilicon production technology, can solve the problems of leakage of toxic and harmful materials sealed by agitators, poor heat exchange effect of a disproportionation kettle jacket, and low extraction rate of raw material components, etc. Continuous production, easy to promote and use, the effect of reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

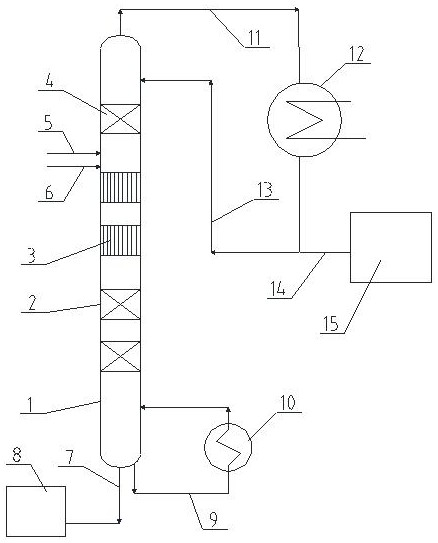

[0013] The method for treating organic silicon low boilers by reactive distillation described in Example 1 comprises the following steps:

[0014] ①Reaction section packing layer treatment: The catalyst aluminum trichloride is supported on the surface of the reaction section packing layer to form a solid catalytic packing layer 3 in the reaction section. Aluminum trichloride is loaded on the surface of the reaction section packing layer by chemical vapor deposition. Vapor phase deposition is a process technology in which the reaction substance reacts chemically under gaseous conditions, and the solid substance is deposited on the surface of the heated solid substrate to obtain a solid material. In the furnace, the mixed gas of aluminum trichloride gas and nitrogen source gas is used as the reaction gas. When the temperature of the reaction chamber reaches an appropriate temperature, the reaction gas is introduced to control the deposition of the substance by adjusting the react...

Embodiment 2

[0019] The method for processing organosilicon low boilers by reactive distillation described in Example 2 comprises the following steps:

[0020] ①Reaction section packing layer treatment: The catalyst aluminum trichloride is supported on the surface of the reaction section packing layer to form a solid catalytic packing layer 3 in the reaction section. Aluminum trichloride is loaded on the surface of the reaction section packing layer by chemical vapor deposition. Vapor phase deposition is a process technology in which the reaction substance reacts chemically under gaseous conditions, and the solid substance is deposited on the surface of the heated solid substrate to obtain a solid material. In the furnace, the mixed gas of aluminum trichloride gas and nitrogen source gas is used as the reaction gas. When the temperature of the reaction chamber reaches an appropriate temperature, the reaction gas is introduced to control the deposition of the substance by adjusting the react...

Embodiment 3

[0025] The method for treating organic silicon low boilers by reactive distillation described in Example 3 comprises the following steps:

[0026] ①Reaction section packing layer treatment: The catalyst aluminum trichloride is supported on the surface of the reaction section packing layer to form a solid catalytic packing layer 3 in the reaction section. Aluminum trichloride is loaded on the surface of the reaction section packing layer by chemical vapor deposition. Vapor phase deposition is a process technology in which the reaction substance reacts chemically under gaseous conditions, and the solid substance is deposited on the surface of the heated solid substrate to obtain a solid material. In the furnace, the mixed gas of aluminum trichloride gas and nitrogen source gas is used as the reaction gas. When the temperature of the reaction chamber reaches an appropriate temperature, the reaction gas is introduced to control the deposition of the substance by adjusting the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com