Energy-saving and environment-friendly equipment with waste heat recovery function and application method

An energy saving, environmental protection, waste heat recovery technology, applied in lighting and heating equipment, combustion methods, water heaters, etc., can solve problems such as large energy loss, acid rain, air pollution, etc., to improve waste heat utilization efficiency, improve industrial efficiency, Good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

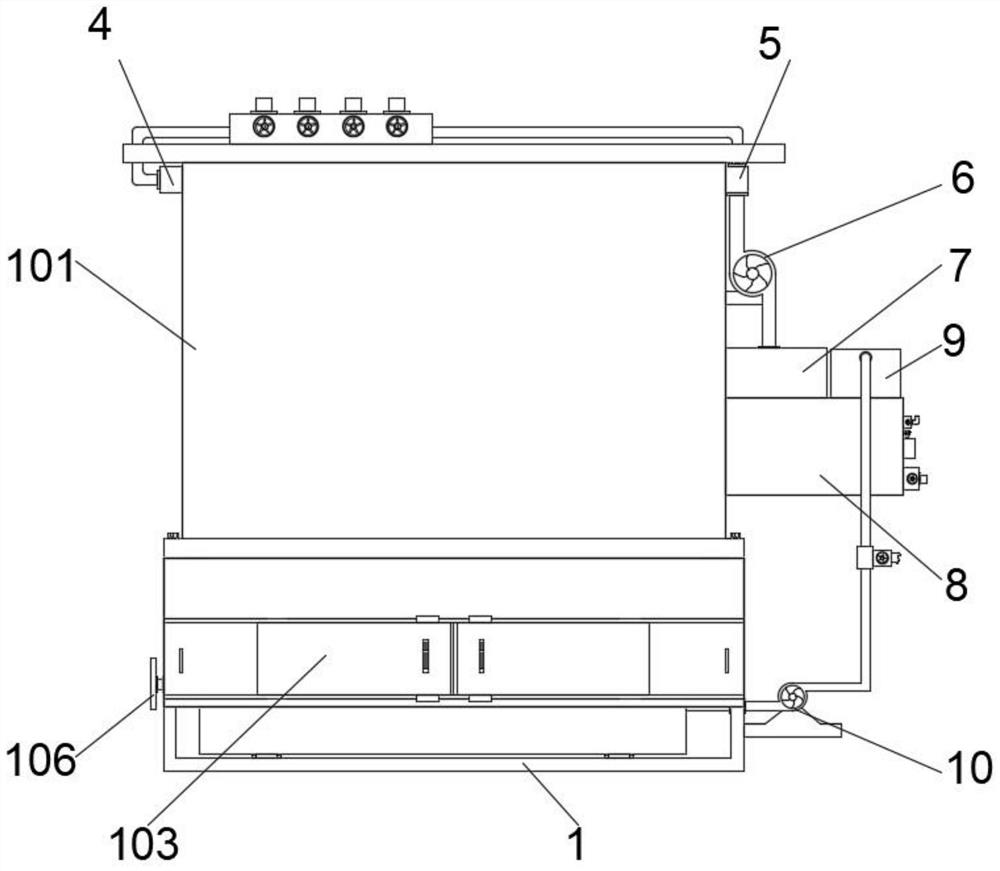

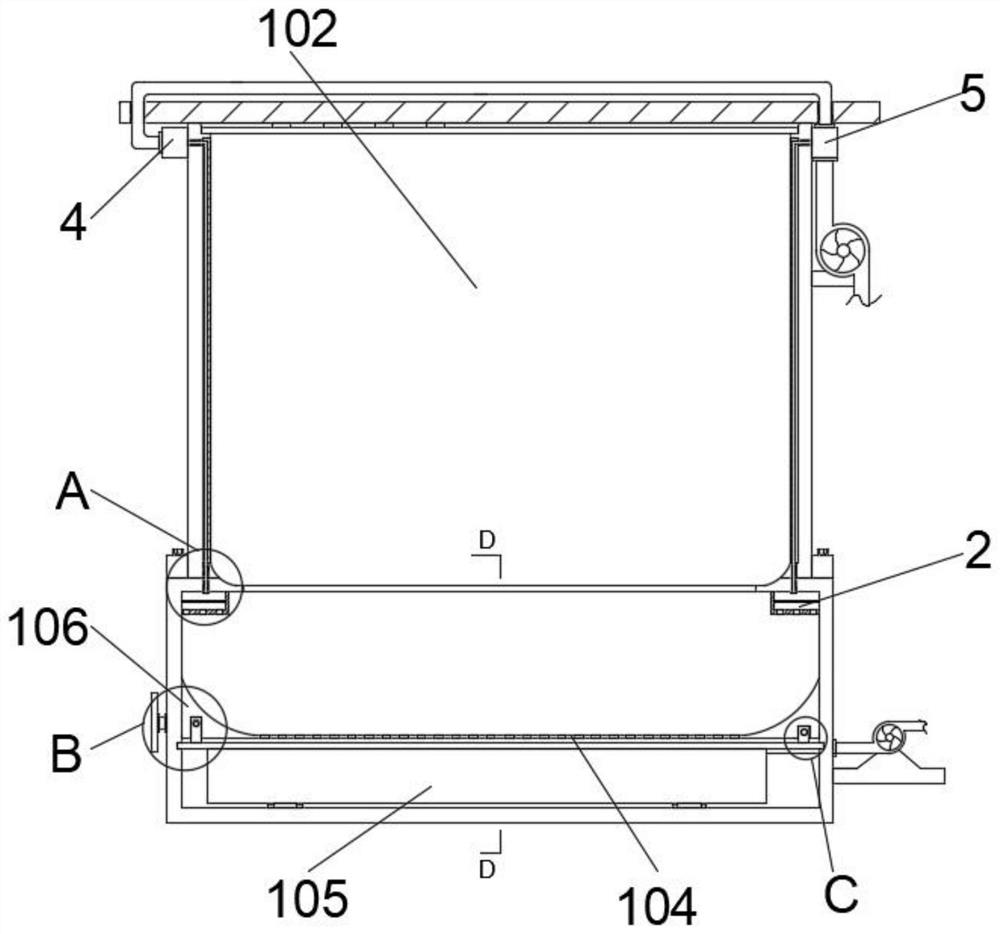

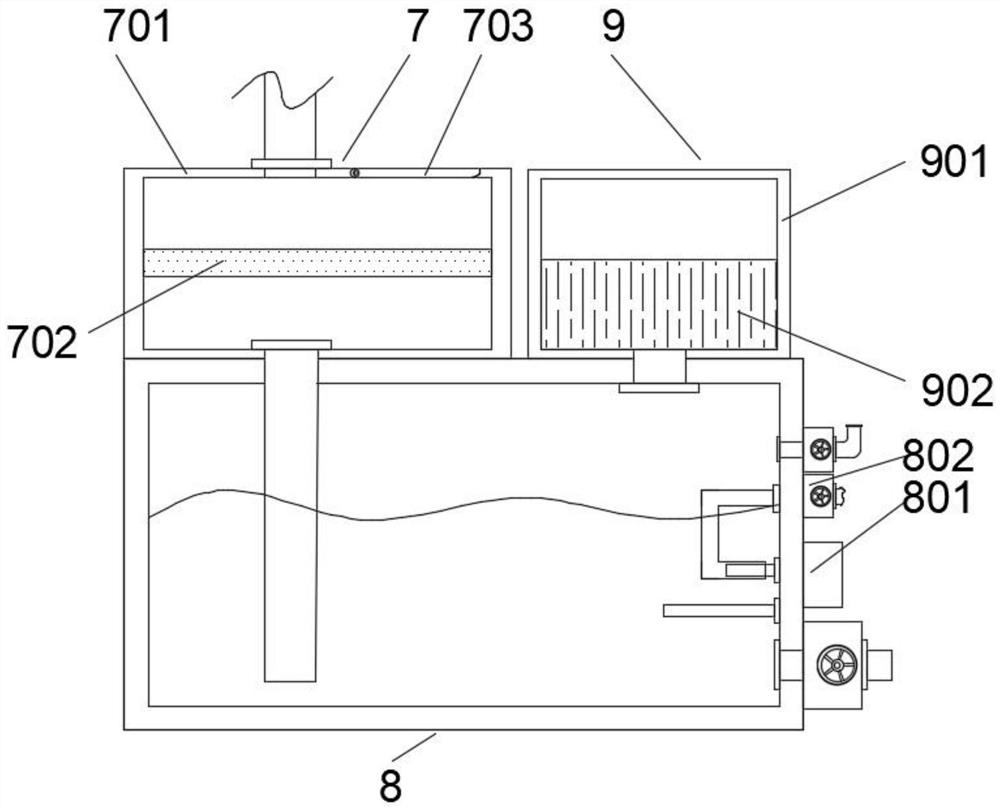

[0041] Such as Figure 1-Figure 5 As shown, an energy-saving and environment-friendly device with waste heat recovery function includes a combustion bin 1, an anti-scald casing 101 fixed on the top of the combustion bin 1 by bolts, a water tank 102 fixedly arranged in the anti-scald casing 101, a sliding set The side-by-side door 103 on the combustion chamber 1 side plate, the dust filter 104 fixedly arranged in the combustion chamber 1 and the dust collection box 105 with the upper opening on the bottom end of the combustion chamber 1 are slidably arranged, and the anti-scald housing 101 top is fixedly installed There are water inlet valve, water outlet valve, replenishment valve and pressure relief valve. The bottom end of the water outlet valve runs through the outer wall of the anti-scald housing 101 through a pipe and extends to the bottom. Open the water outlet valve to extract hot water, and the water inlet valve is used for water supply and replenishment The valve is u...

Embodiment 2

[0049] In Example 1, although the waste heat of the flue gas produced by coal combustion is used efficiently, at the same time, the sulfur dioxide in the flue gas is desulfurized to generate sulfur trioxide, and then sulfur trioxide and water generate sulfuric acid and then the sulfuric acid is utilized to improve the enterprise. benefit and protect the environment, but there are also deficiencies in it. When the coal is placed on the dust screen 104, the coal particles are of different sizes. The leaks of the dust leakage screen 104 fall into the dust box 105, resulting in a waste of resources;

[0050] Such as Figure 6-Figure 8 As shown, a kind of energy-saving and environment-friendly equipment with waste heat recovery function, a switch assembly 106 for preventing coal from falling is provided between the dust leakage screen 104 and the dust collection box 105, the switch assembly 106 includes a rotating rod 1061, fixedly sleeved on the rotating rod The first bevel gear ...

Embodiment 3

[0053] In embodiment 2, the relatively sliding slide plate 1066 is set to block the dust leakage screen 104, which solves the problem that the coal with smaller particles has directly fallen into the dust box 105, but when the slide plate 1066 blocks the dust leakage screen 104, the coal is still in the dust leakage screen 104. The accumulation at the hole may cause the leakage hole to be blocked, which is not conducive to the collection and recycling of dust;

[0054] Such as Figure 9 As shown, a kind of energy-saving and environment-friendly equipment with waste heat recovery function, a vibration assembly 1069 for shaking the dust leakage screen 104 is provided between the sliding plate 1066 and the dust leakage screen 104, and a vibration chute adapted to the vibration assembly 1069 is provided on the sliding plate 1066 The tremor assembly 1069 is used to vibrate the dust filter 104, so that the dust is shaken down on the dust filter 104. The tremor assembly 1069 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com