MOF-derived composite wave-absorbing material as well as preparation method and application thereof

A technology of composite absorbing materials and mixtures, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of narrow effective absorption bandwidth, complex synthesis and high density of composite absorbing materials, and achieve favorable impedance matching , Excellent electromagnetic wave attenuation ability, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a MOF-derived composite wave-absorbing material, comprising the steps of:

[0034] (1): 166mg (1mmol) H 2 BDC powder was dissolved in 16.6mL DMF solution, then the mixed solution was stirred at 1000rpm on a magnetic stirrer for 10min, after stirring, 270mg (1 mmol) FeCl was added 3 ·6H 2 O and 128 mg (0.5 mmol) Ni(acac) 2 The powder was mixed by ultrasound for 20 minutes, and then the mixture was transferred to a stainless steel autoclave at 120°C for hydrothermal reaction, and the hydrothermal reaction time was 12 hours. After the completion of the hydrothermal reaction, cool to room temperature and centrifuge to obtain a brown precipitate, which is then washed 6 times with DMF and ethanol. Finally, the brown product was dried overnight in an oven at 70 °C.

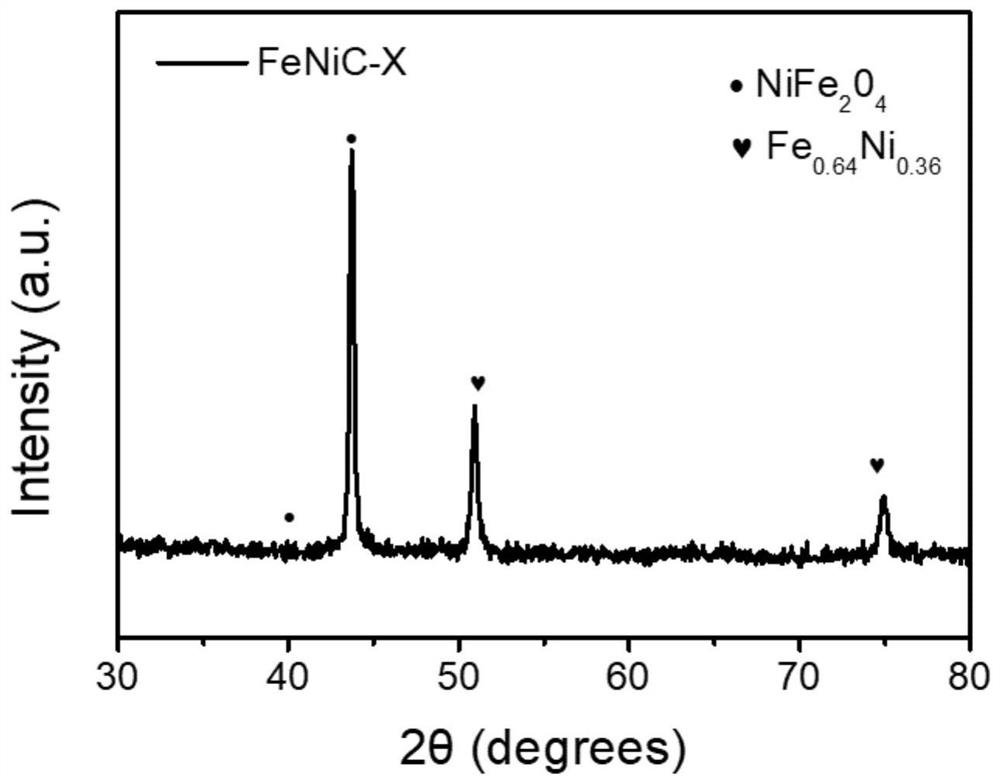

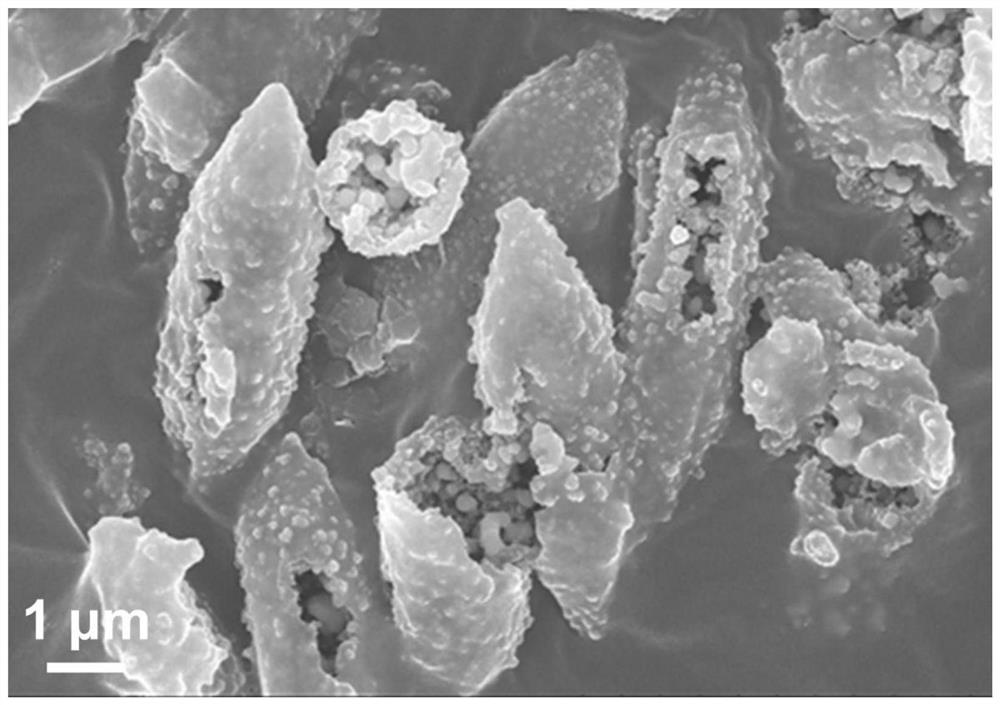

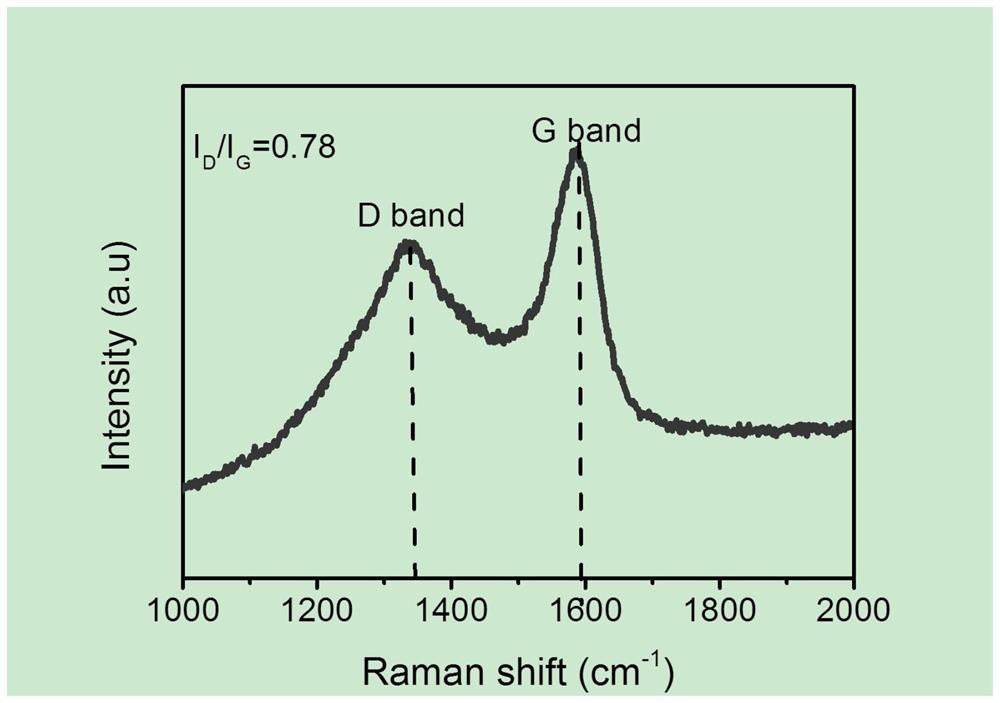

[0035] (2): Put the FeNi-MIL-101 prepared in step 1 into a tube furnace, and heat up to 700°C for 2 hours at a rate of 5°C / min in a nitrogen atmosphere. After the calcination, the final...

Embodiment 2

[0041] A preparation method of a MOF-derived composite wave-absorbing material, comprising the steps of:

[0042] (1): 166mg (1mmol) H 2 BDC powder was dissolved in 16.6mL DMF solution, then the mixed solution was stirred at 1000rpm on a magnetic stirrer for 10min, after stirring, 270mg (1 mmol) FeCl was added 3 ·6H 2 O and 128 mg (0.5 mmol) Ni(acac) 2 The powder was mixed by ultrasound for 20 minutes, and then the mixture was transferred to a stainless steel autoclave at 120°C for hydrothermal reaction, and the hydrothermal reaction time was 12 hours. After the completion of the hydrothermal reaction, cool to room temperature and centrifuge to obtain a brown precipitate, which is then washed 6 times with DMF and ethanol. Finally, the brown product was dried overnight in an oven at 70 °C.

[0043] (2): Put the FeNi-MIL-101 prepared in step 1 into a tube furnace, and heat up to 600°C for 2 hours at a rate of 5°C / min in a nitrogen atmosphere. After the calcination, the final...

Embodiment 3

[0046] A preparation method of a MOF-derived composite wave-absorbing material, comprising the steps of:

[0047] (1): 166mg (1mmol) H 2 BDC powder was dissolved in 16.6mL DMF solution, then the mixed solution was stirred at 1000rpm on a magnetic stirrer for 10min, after stirring, 270mg (1 mmol) FeCl was added 3 ·6H 2 O and 128 mg (0.5 mmol) Ni(acac) 2 The powder was mixed by ultrasound for 20 minutes, and then the mixture was transferred to a stainless steel autoclave at 120°C for hydrothermal reaction, and the hydrothermal reaction time was 12 hours. After the completion of the hydrothermal reaction, it was cooled to room temperature and centrifuged to obtain a brown precipitate, which was then washed 6 times with DMF and ethanol. Finally, the brown product was dried overnight in an oven at 70 °C.

[0048] (2): Put the FeNi-MIL-101 prepared in step 1 into a tube furnace, and heat up to 800°C for 2 hours at a rate of 5°C / min in a nitrogen atmosphere. After the calcination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com