Probiotic-rich fruit and vegetable crisp chips and preparation method thereof

A technology of fruit and vegetable chips and probiotics, which is applied to the preservation of fruits and vegetables, preservation of fruits/vegetables by dehydration, preservation of food ingredients as antimicrobials, etc. Immunity, growth inhibition, unique flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

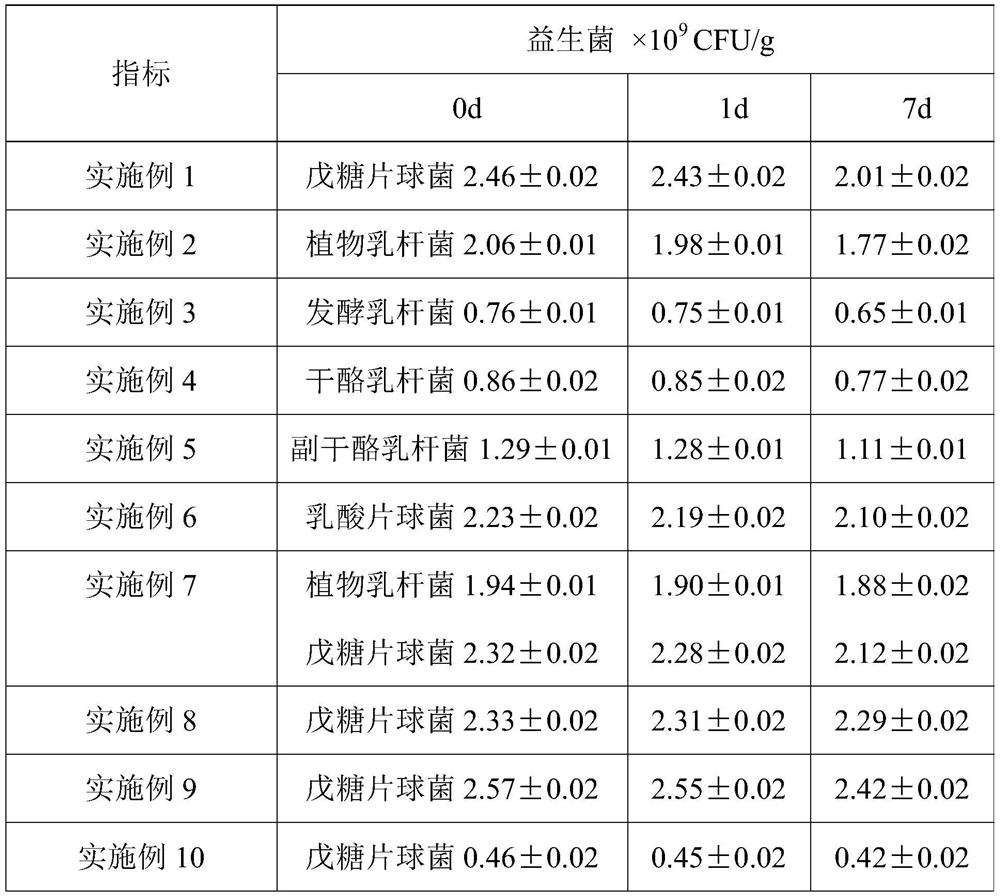

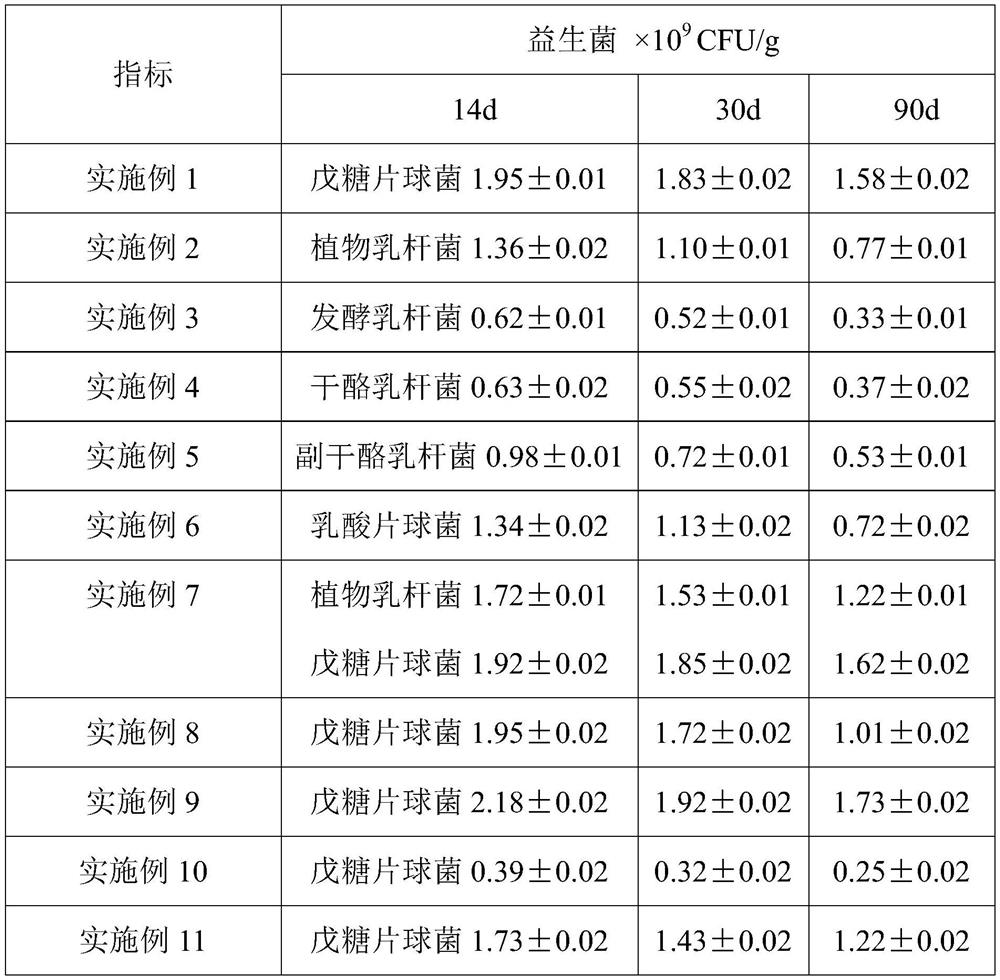

Examples

Embodiment 1

[0048] The preparation method of probiotic fruit and vegetable chips comprises the following steps:

[0049] (1) Fresh fruits and vegetables (green peppers, cauliflowers, radishes, and purple cabbage with a mass ratio of 1:1:1:1 were selected in this embodiment) were cleaned, drained, and sliced (thickness 1-3mm) to obtain fruit and vegetable slices; Blanch the cut fruit and vegetable slices, the blanching temperature is 100°C, and the blanching time is 3 minutes; when cooling, use ultrapure water to cool step by step, cool to 15°C with ultrapure water, and drain.

[0050] (2) Heat-adapt the suspension of Pediococcus pentosaceae in a water bath at 47°C for 60 minutes.

[0051] (3) Put the drained fruit and vegetable slices into a fermenter, add probiotic suspension, stir evenly, seal the mouth of the tank, put it in an incubator, and incubate at 37°C in the dark for 12 hours; The suspension concentration is 10 10 CFU / mL, the amount of bacterial solution added: 10 10 CFU / 1...

Embodiment 2

[0054] The preparation method of probiotic fruit and vegetable chips comprises the following steps:

[0055] (1) Fresh fruits and vegetables (green peppers, cauliflowers, radishes, and purple cabbage with a mass ratio of 1:1:1:1 were selected in this embodiment) were cleaned, drained, and sliced (thickness 1-3mm) to obtain fruit and vegetable slices; Blanch the cut fruit and vegetable slices, the blanching temperature is 95°C, and the blanching time is 2min; when cooling, use ultrapure water to cool step by step, cool to 25°C with ultrapure water, and drain.

[0056] (2) Heat-adapt the Lactobacillus plantarum suspension in a water bath at 45°C for 30 minutes.

[0057] (3) Put the drained fruit and vegetable slices into a fermentation tank, add probiotic Lactobacillus plantarum suspension, stir evenly, seal the tank mouth, put it in an incubator, and incubate at 30°C for 24 hours in the dark; adjust the probiotics The species is Lactobacillus plantarum suspension concentrati...

Embodiment 3

[0060] The preparation method of probiotic fruit and vegetable chips comprises the following steps:

[0061] (1) Fresh fruits and vegetables (green peppers, cauliflowers, radishes, and purple cabbage with a mass ratio of 1:1:1:1 were selected in this embodiment) were cleaned, drained, and sliced (thickness 1-3mm) to obtain fruit and vegetable slices; Blanch the cut fruit and vegetable slices, the blanching temperature is 98°C, and the blanching time is 5 minutes; when cooling, use ultrapure water to cool step by step, cool to 20°C with ultrapure water, and drain.

[0062] (2) The Lactobacillus fermentum suspension was heat-adapted in a water bath at 52°C for 20 minutes.

[0063] (3) Put the drained fruit and vegetable slices into a fermentation tank, add probiotic Lactobacillus fermentum suspension, stir evenly, seal the tank mouth, put it in an incubator, and incubate at 35°C for 18 hours in the dark; adjust the probiotics The species is Lactobacillus fermentum suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com