Preparation method of basalt fiber composite material

A technology of basalt fiber and composite material, which is applied in the field of preparation of basalt fiber composite material, can solve problems such as defects of composite material, and achieve the effects of excellent comprehensive performance, low production cost, and avoiding loss of life and property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

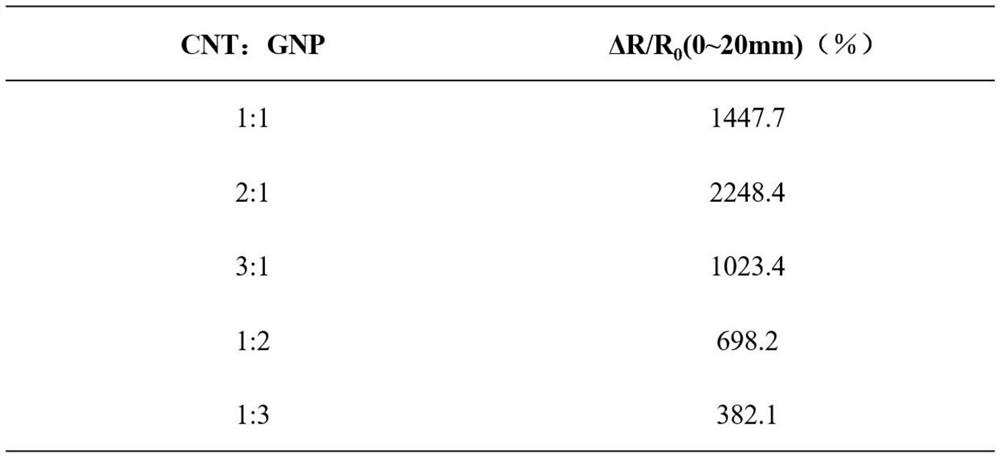

[0031] S1. Put 1g of the mixture of multi-walled carbon nanotubes and graphene nanosheets in a 2-liter beaker according to the mass ratio of 2:1, add ultrapure water to obtain a dispersion with a concentration of 1g / L, and then place the flask on In a cooling tank at 5°C, the mixture was circulated through the ultrasonic transducer using a peristaltic pump. Then the ozone produced by the oxygen concentrator and ozone generator is continuously passed into the dispersion liquid, and this process lasts for 16 hours, so that the multi-walled carbon nanotubes and graphene nanosheets are oxidized;

[0032] S2, 0.06g glacial acetic acid (mass percentage concentration 80%) is added in the dispersion liquid, the pH value of the dispersion liquid is adjusted to 5.8, then 2g cationic polyacrylamide (CPAM) is joined in the dispersion liquid, then in 15 Ultrasonic treatment at ℃ for 4 hours to functionalize the multi-walled carbon nanotubes and graphene nanosheets, so that the oxidized mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com