Agilawood chicken feed additive

A feed additive and agarwood chicken technology, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of high abdominal fat rate and low slaughter rate of chickens raised in cages, so as to improve the body's immunity and promote absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

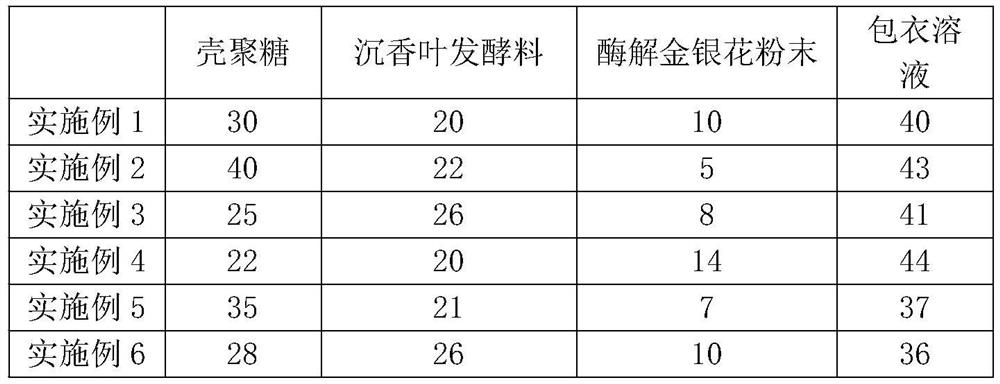

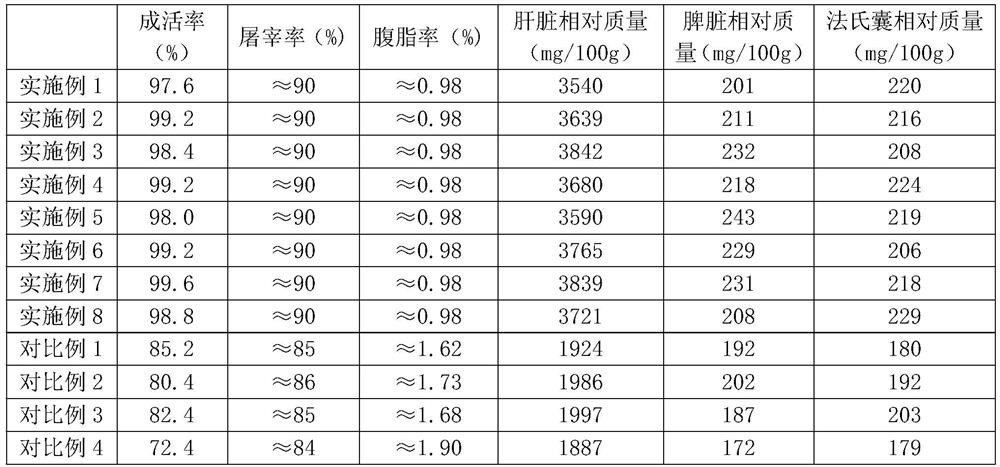

Examples

Embodiment 1

[0024] Preparation of agarwood husk fermentation material: 78kg of low-grade agarwood husks were washed, steamed and killed, then dried in air, then freeze-dried at a low temperature of -30--45°C for 1-5 hours, crushed to 120 meshes, added agarwood seed oil and fermented for 15 days.

[0025] Preparation of enzymatically hydrolyzed honeysuckle: crush honeysuckle, add ethanol with the same volume as honeysuckle, soak at room temperature for 5-8 hours, filter to obtain filter residue, dry naturally at -20~-30°C for 3-5 hours, freeze-dry, slowly warm to room temperature, add pectin water Enzyme hydrolysis for 1-3h, then add β-galactosidase for 2-3h.

[0026] To prepare a coating solution, add stearic acid, glyceride and calcium chloride into an aqueous ethanol solution, and stir evenly to obtain a coating solution.

[0027] A kind of agarwood chicken feed additive, raw material comprises:

[0028] Chitosan 30kg;

[0029] Agarwood husk fermentation material 20kg;

[0030] Enzym...

Embodiment 7

[0039] Preparation of agarwood leaf fermentation material: wash 78kg of low-grade agarwood leaves, cook and fix them, then dry them in air, then freeze-dry them at a low temperature of -30--45°C for 1-5 hours, crush them to 120 meshes, add agarwood seed oil and ferment for 15 days.

[0040] Preparation of enzymatically hydrolyzed honeysuckle: crush honeysuckle, add ethanol with the same volume as honeysuckle, soak at room temperature for 5-8 hours, filter to obtain filter residue, dry naturally at -20~-30°C for 3-5 hours, freeze-dry, slowly warm to room temperature, add pectin water Enzyme hydrolysis for 1-3h, then add β-galactosidase for 2-3h.

[0041] To prepare a coating solution, add stearic acid, glyceride and calcium chloride into an aqueous ethanol solution, and stir evenly to obtain a coating solution.

[0042] A kind of agarwood chicken feed additive, raw material comprises:

[0043] Chitosan 30kg;

[0044] Agarwood leaf fermentation material 20kg;

[0045] Enzymol...

Embodiment 8

[0052] Preparation of agarwood raw material fermentation material: wash 38kg of agarwood leaves and 40kg of low-grade agarwood husks, steam and kill them, then dry them in air, then freeze-dry them at a low temperature of -30--45℃ for 1-5 hours, crush them into 120 meshes, add agarwood seed oil for fermentation 15 days.

[0053] Preparation of enzymatically hydrolyzed honeysuckle: crush honeysuckle, add ethanol with the same volume as honeysuckle, soak at room temperature for 5-8 hours, filter to obtain filter residue, dry naturally at -20~-30°C for 3-5 hours, freeze-dry, slowly warm to room temperature, add pectin water Enzyme hydrolysis for 1-3h, then add β-galactosidase for 2-3h.

[0054] To prepare a coating solution, add stearic acid, glyceride and calcium chloride into an aqueous ethanol solution, and stir evenly to obtain a coating solution.

[0055] A kind of agarwood chicken feed additive, raw material comprises:

[0056] Chitosan 30kg;

[0057] Agarwood raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com