Method for extracting rebaudioside A, stevioside and stevia polyphenol from stevia rebaudiana and application thereof

A technology of stevia rebaudiana and stevioside, which is applied in the field of extracting active ingredients of plants, can solve the problems of multiple solid wastes, and achieve the effects of strong operability, reduced production costs, and convenient follow-up purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The embodiment of the present invention provides a method for extracting rebaudioside A, stevioside and stevia polyphenols from Stevia rebaudiana, which specifically includes the following steps:

[0058] S1, water extraction

[0059] Weigh 100g of stevia leaf raw material after drying and pulverizing, use 1000ml of pure water to reflux and extract at a temperature of 80°C for 90min, separate the filter residue and filtrate, and then use 700ml of pure water to reflux and extract for 60min under the same conditions. time, combined 3 times of water extracts obtained, concentrated to 300ml;

[0060] S2, precipitation

[0061] Add saturated lime water to the concentrated solution obtained in S1 to adjust its pH = 10, and centrifuge after standing for 1 hour to obtain supernatant and precipitate;

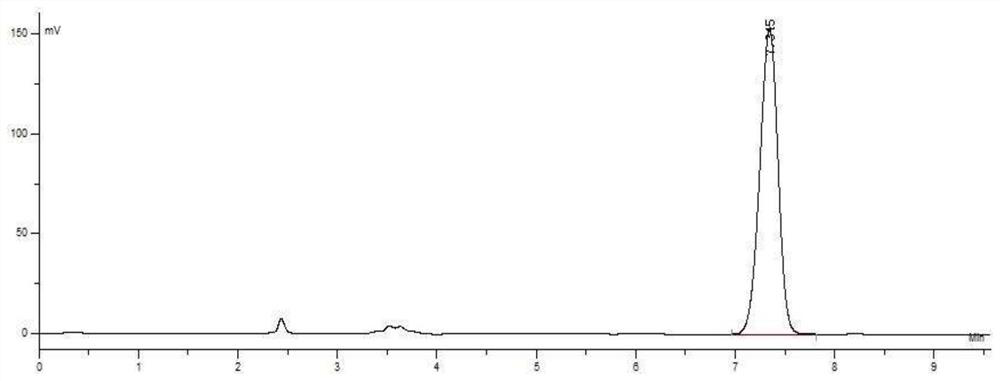

[0062] S3. Purification of steviol glycosides

[0063] Take the supernatant obtained in S2 and put it on the D101 macroporous resin column, and control the sample loading flow ...

Embodiment 2

[0067] The embodiment of the present invention provides a method for extracting rebaudioside A, stevioside and stevia polyphenols from Stevia rebaudiana, which specifically includes the following steps:

[0068] S1, water extraction

[0069] Weigh 1000g of the stevia leaf raw material after drying and pulverizing, use 12000ml of pure water to reflux and extract at a temperature of 78°C for 100min, separate the filter residue and filtrate, and then use 9000ml of pure water to reflux and extract for 90min under the same conditions. time, combined 3 times of obtained water extracts, concentrated to 3500ml;

[0070] S2, precipitation

[0071] Add saturated lime water to the concentrated solution obtained in S1 to adjust its pH=9.5, let it stand for 80 minutes, and centrifuge to obtain supernatant and precipitate;

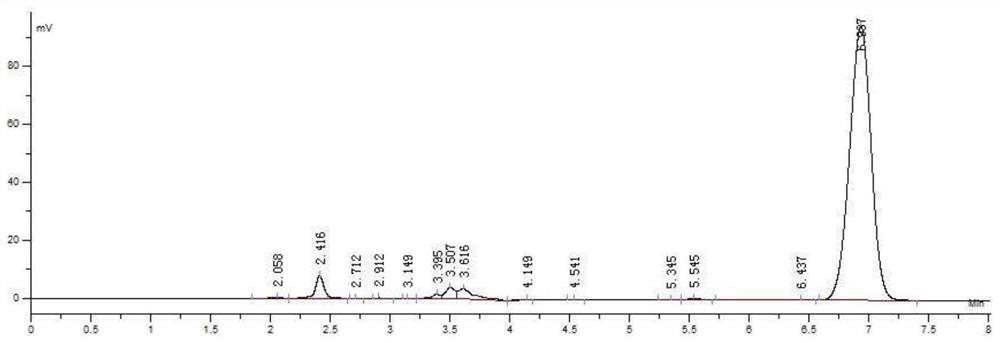

[0072] S3. Purification of steviol glycosides

[0073] Take the supernatant obtained in S2 and put it on the AB-8 macroporous resin column, and control the sample lo...

Embodiment 3

[0077] The embodiment of the present invention provides a method for extracting rebaudioside A, stevioside and stevia polyphenols from Stevia rebaudiana, which specifically includes the following steps:

[0078] S1, water extraction

[0079] Weigh 100kg of dried and pulverized stevia leaf raw materials, use 1000L of pure water to reflux and extract at a temperature of 80°C for 90 minutes, separate the filter residue and filtrate, and then use 800L of pure water to reflux and extract for 60 minutes under the same conditions. time, combined 3 times of water extracts obtained, concentrated to 250L;

[0080] S2, precipitation

[0081] Add saturated lime water to the concentrated solution obtained in S1 to adjust its pH = 10.0, let stand for 1 hour and then centrifuge to obtain supernatant and precipitate;

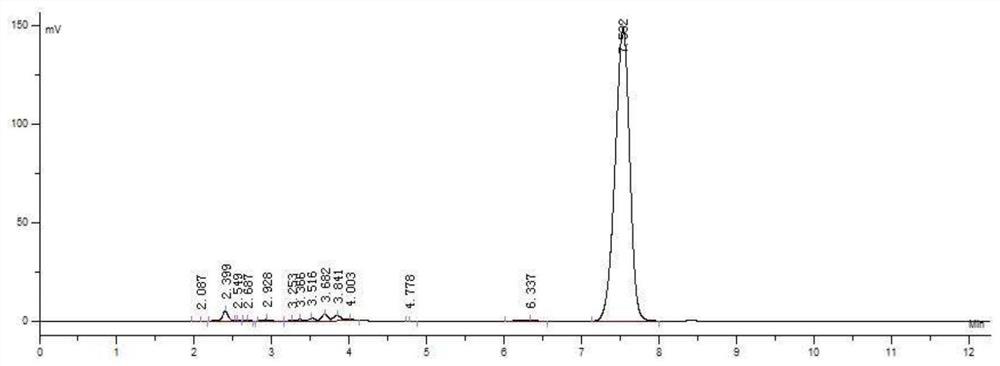

[0082] S3. Purification of steviol glycosides

[0083] Take the supernatant obtained in S2 and put it on the HP-20 macroporous resin column, and control the sample loading f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com