A kind of co-modified organosilicon composition and preparation method thereof

A technology of co-modification and composition, applied in the directions of organic cleaning compositions, inorganic/elementary cleaning compositions, softening compositions, etc., can solve the problems of high viscosity of silicon paste, easy precipitation, secondary pollution, etc., and achieve a lifting effect. Persistence, soft and fluffy feel, good effect of anti-foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A co-modified silicone composition includes a co-modified linear hydrogen-containing polysiloxane, vinyl alkyl glycidyl ether, dialkyl amine, methyl silicone resin, silica and a catalyst.

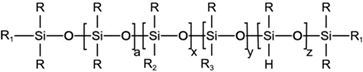

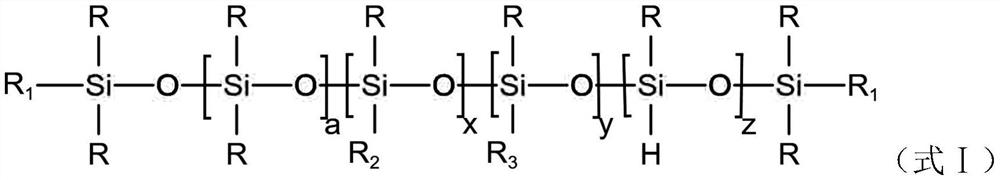

[0048] The general structural formula of the co-modified hydrogen-containing polysiloxane is:

[0049]

[0050] Among them, a=5; x=5; y=10; z=5;

[0051] R is a methyl group, R1 is a dodecyl group, R2 is a propyl polyether group containing 15 mol of polyoxypropylene, a methyl group is terminated, and R3 is a-methylphenethyl group.

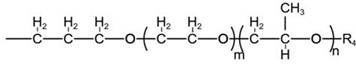

[0052] Further, the general structural formula of the R substituent is:

[0053]

[0054] Wherein, m=0, n=15, and R4 is a methyl group.

[0055] Further, the vinyl alkyl glycidyl ether is allyl glycidyl ether;

[0056] Further, the dialkylamine is diethylamine.

[0057] Further, the methyl silicone resin is methyl MQ silicone resin, wherein the molar ratio of M units to Q units is 0.8:1, and the molecular weight of the methyl MQ silicone resin i...

Embodiment 2

[0068] A co-modified silicone composition includes a co-modified linear hydrogen-containing polysiloxane, vinyl alkyl glycidyl ether, dialkyl amine, methyl silicone resin, silica and a catalyst.

[0069] The general structural formula of the co-modified hydrogen-containing polysiloxane is:

[0070]

[0071] Among them, a=20; x=10; y=20; z=10;

[0072] R is methyl, R1 is dodecyl, R2 is a propyl polyether group containing 5 mol of polyoxyethylene and 10 mol of polyoxypropylene, methyl terminated, and R3 is α-methylphenethyl.

[0073] Further, the general structural formula of the R substituent is:

[0074]

[0075] Wherein, m=5, n=10, and R4 is a methyl group.

[0076] Further, the vinyl alkyl glycidyl ether is allyl glycidyl ether;

[0077] Further, the dialkylamine is diethylamine.

[0078] Further, the methyl silicone resin is methyl MQ silicone resin, wherein the molar ratio of M units to Q units is 0.8:1, and the molecular weight of the methyl MQ silicone resin is...

Embodiment 3

[0089] A co-modified silicone composition includes a co-modified linear hydrogen-containing polysiloxane, vinyl alkyl glycidyl ether, dialkyl amine, methyl silicone resin, silica and a catalyst.

[0090] The general structural formula of the co-modified hydrogen-containing polysiloxane is:

[0091]

[0092] Among them, a=20; x=10; y=25; z=5;

[0093] R is methyl, R1 is dodecyl, R2 is a propyl polyether group containing 2 mol of polyoxyethylene and 20 mol of polyoxypropylene, methyl terminated, and R3 is α-methylphenethyl.

[0094] Further, the general structural formula of the R substituent is:

[0095]

[0096] Wherein, m=5, n=10, and R4 is a methyl group.

[0097] Further, the vinyl alkyl glycidyl ether is allyl glycidyl ether;

[0098] Further, the dialkylamine is diethylamine.

[0099] Further, the methyl silicone resin is methyl MQ silicone resin, wherein the molar ratio of M units to Q units is 0.8:1, and the molecular weight of the methyl MQ silicone resin is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com