Olefin separation device for upgrading coal-made stable heavy oil

A technology for olefin separation and heavy oil, which is applied in hydrocarbon distillation, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as difficulty in obtaining target narrow carbon number olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

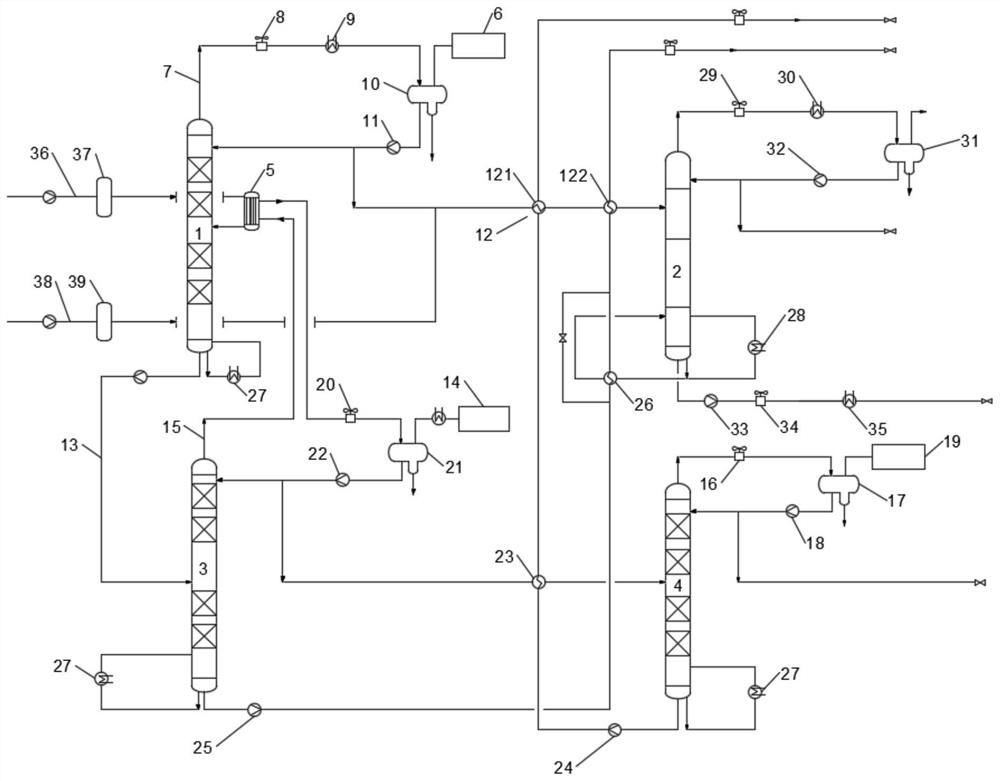

[0036] Such as figure 1As shown, the core of the present invention is to provide an olefin separation device for upgrading stable heavy oil from coal, including: a heavy oil preheater 5 for preheating heavy oil from coal, with a preheating temperature of 210°C; Separation tower 1, the outlet end of heavy oil preheater 5 is connected with the middle part of heavy oil separation tower 1, and heavy oil separation tower 1 is provided with C11 and lighter hydrocarbon gas phase outlet and C12 and heavier hydrocarbon outlet, and heavy oil separation tower 1 top is provided with There is a first vacuum 6; the light hydrocarbon separation tower 2, C11 and lighter hydrocarbon gas phase outlets are connected with the middle part of the light hydrocarbon separation tower 2 through the light hydrocarbon pipeline 7, and the light hydrocarbon pipeline 7 is successively provided with a light hydrocarbon air cooler 8, Light hydrocarbon water cooler 9, light hydrocarbon reflux tank 10, light hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com