Cold plasma gas phase preparation method of tin dioxide nanoparticles

A cold plasma and nanoparticle technology, applied in the direction of nanotechnology, gaseous chemical plating, metal material coating process, etc., can solve the problem of inability to obtain self-supporting nanoparticle materials with grain size, nanoparticle crystallinity, and purity. Problems such as control, difficulty in obtaining ultrafine nanoparticles, etc., to achieve the effects of short cycle time, high yield, and controllable crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A cold plasma vapor phase preparation method of tin dioxide nanoparticles of the present invention, the specific preparation method is as follows:

[0032] (1) Turn on the vacuum pump, purge the plasma chamber and gas path with nitrogen, and evacuate to reduce the pressure in the plasma system to about 1Pa;

[0033] (2) feed argon gas into the plasma chamber, the flow rate of argon gas is 450 sccm; turn on the radio frequency source, adjust the power to 500W, and generate argon plasma;

[0034] (3) Pass O2 into the plasma chamber from the inner pipe of the intake pipe 2 , O 2 The volume flow rate of the carrier gas is 50 sccm, tin tetrachloride is continuously passed into the plasma chamber by the carrier gas, and the volume flow rate of the carrier gas is 50 sccm;

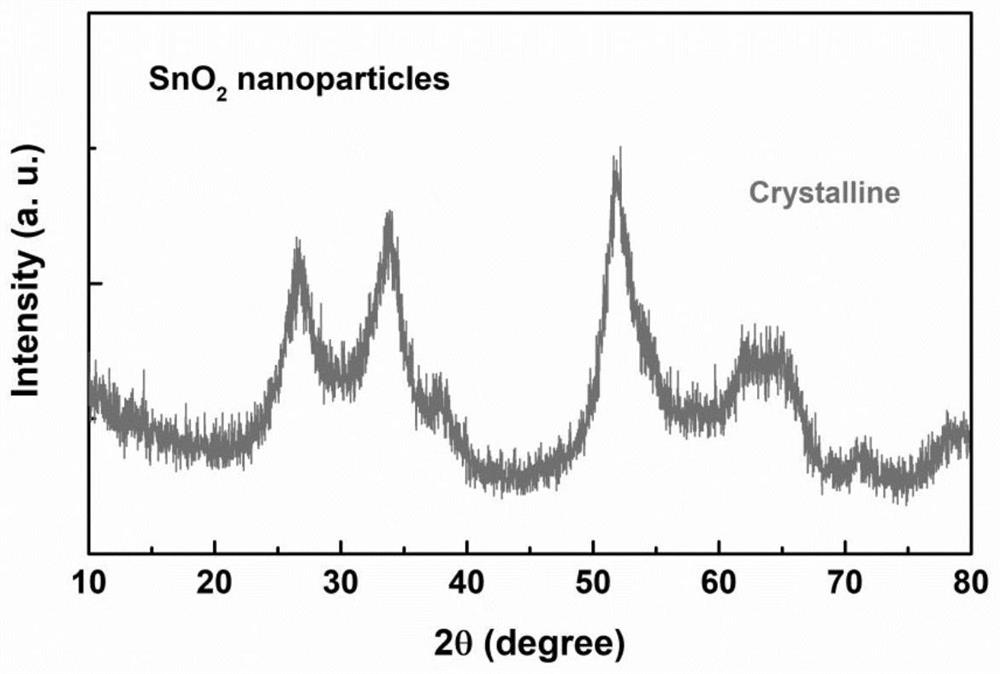

[0035] (4) Control the air pressure in the plasma chamber at 200Pa, adjust the matching box of the radio frequency source, make the load power fully match the load power, and collect the tin dioxide nanop...

Embodiment 2

[0037] A cold plasma vapor phase preparation method of tin dioxide nanoparticles of the present invention, the specific preparation method is as follows:

[0038] (1) Turn on the vacuum pump, purge the plasma chamber and gas path with nitrogen, and evacuate to reduce the pressure in the plasma system to about 1Pa;

[0039] (2) Pass into argon gas in the plasma chamber, the flow rate of argon gas is 450sccm; Turn on the radio frequency source, adjust the power to 200W, produce argon plasma;

[0040] (3) Pass O2 into the plasma chamber from the inner pipe of the intake pipe 2 , O 2 The volume flow rate of the carrier gas is 50 sccm, tin tetrachloride is continuously passed into the plasma chamber by the carrier gas, and the volume flow rate of the carrier gas is 50 sccm;

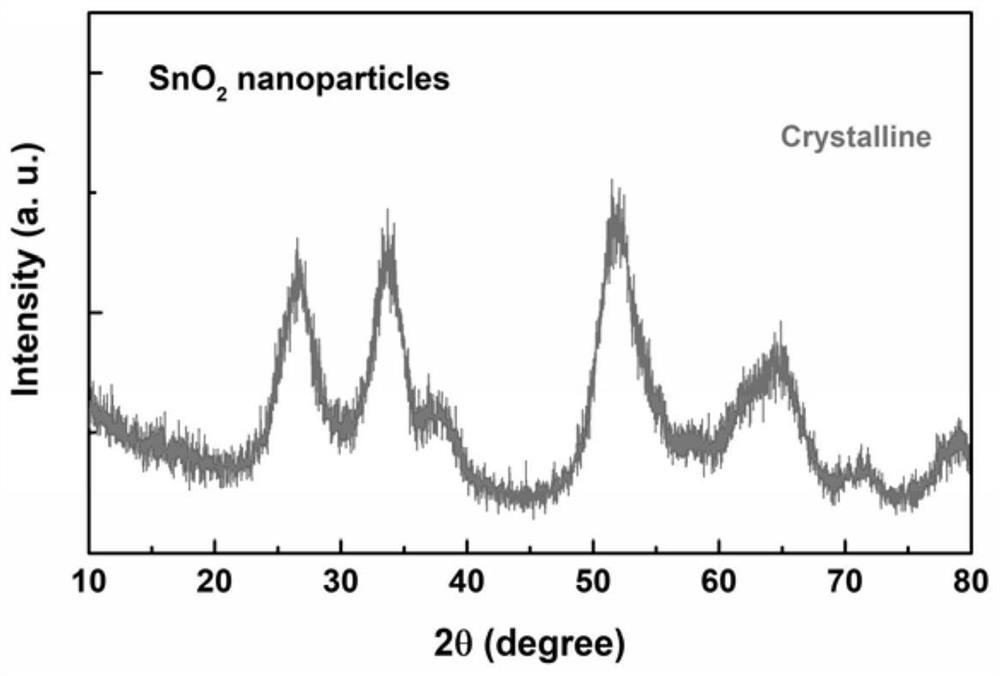

[0041] (4) Control the air pressure in the plasma chamber at 200Pa, adjust the matching box of the radio frequency source, make the load power fully match the load power, and collect the tin dioxide nanopart...

Embodiment 3

[0043] A cold plasma vapor phase preparation method of tin dioxide nanoparticles of the present invention, the specific preparation method is as follows:

[0044] (1) Turn on the vacuum pump, purge the plasma chamber and gas path with nitrogen, and evacuate to reduce the pressure in the plasma system to about 1Pa;

[0045] (2) feed argon gas into the plasma chamber, the flow rate of argon gas is 450 sccm; open the radio frequency source, adjust the power to 50W, and generate argon plasma;

[0046] (3) Pass O2 into the plasma chamber from the inner pipe of the intake pipe 2 , O 2 The volume flow rate of the carrier gas is 50 sccm, tin tetrachloride is continuously passed into the plasma chamber by the carrier gas, and the volume flow rate of the carrier gas is 50 sccm;

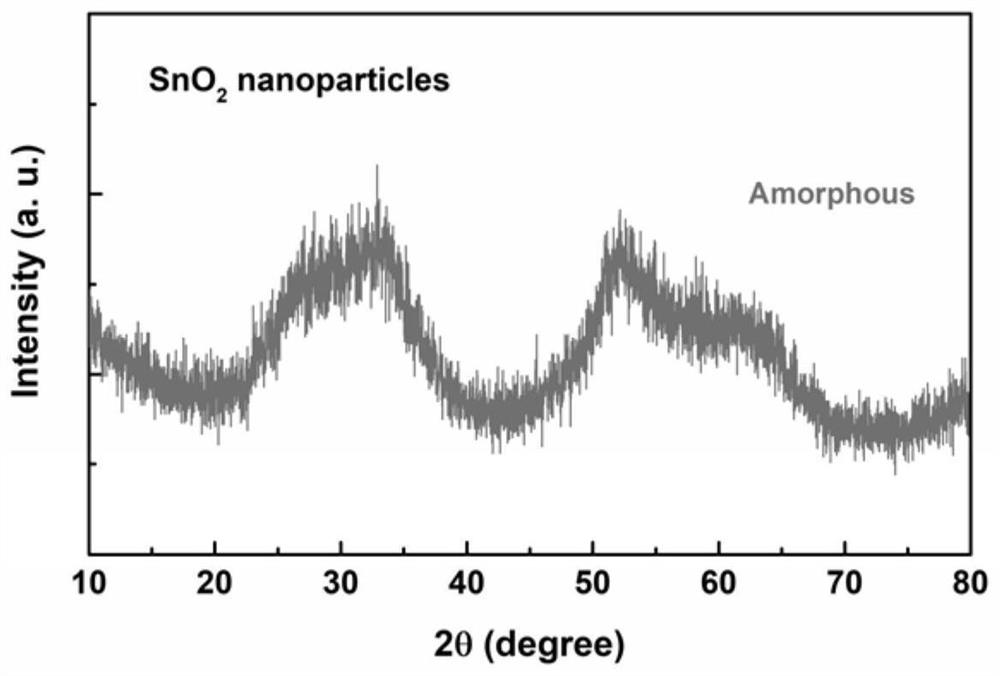

[0047] (4) Control the air pressure in the plasma chamber at 200Pa, adjust the matching box of the radio frequency source, make the load power fully match the load power, and collect the tin dioxide nanoparti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com