Horizontal super-oriented carbon nanotube bundle array and soft lock laddering preparation method thereof

A carbon nanotube bundle and carbon nanotube technology, applied in the field of nanoelectronic devices, can solve the problems of large aspect ratio, easy introduction of impurities, short length of carbon nanotubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

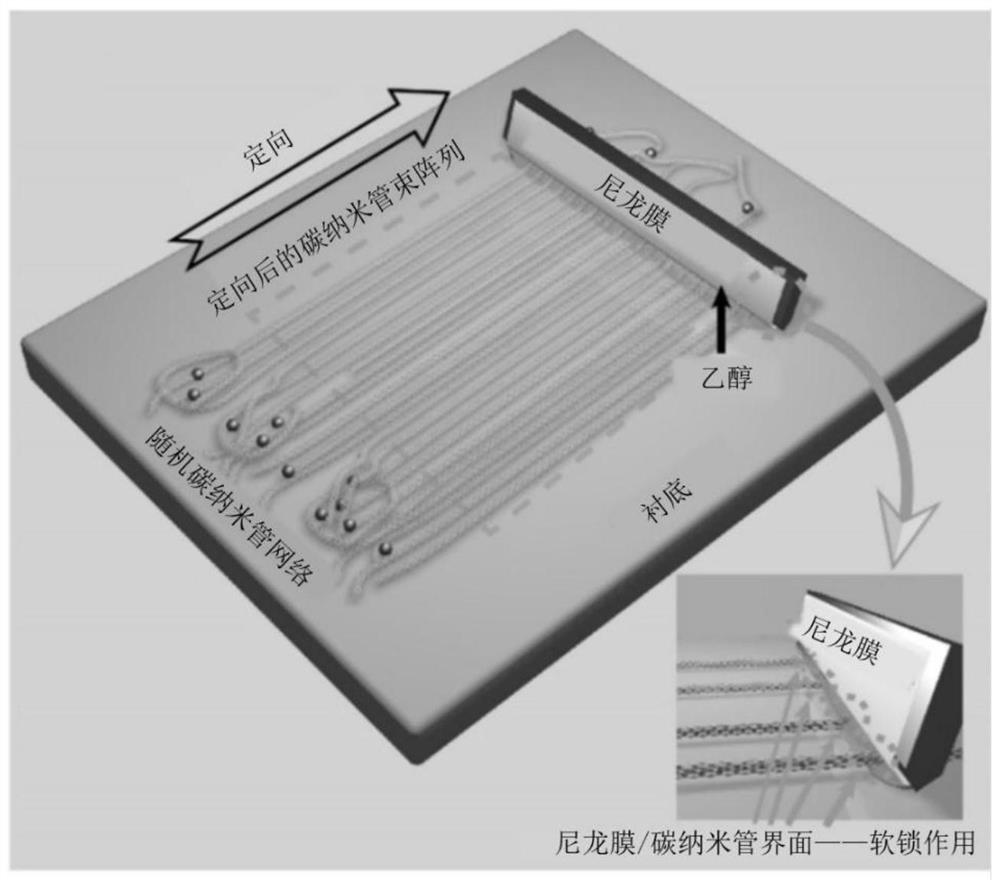

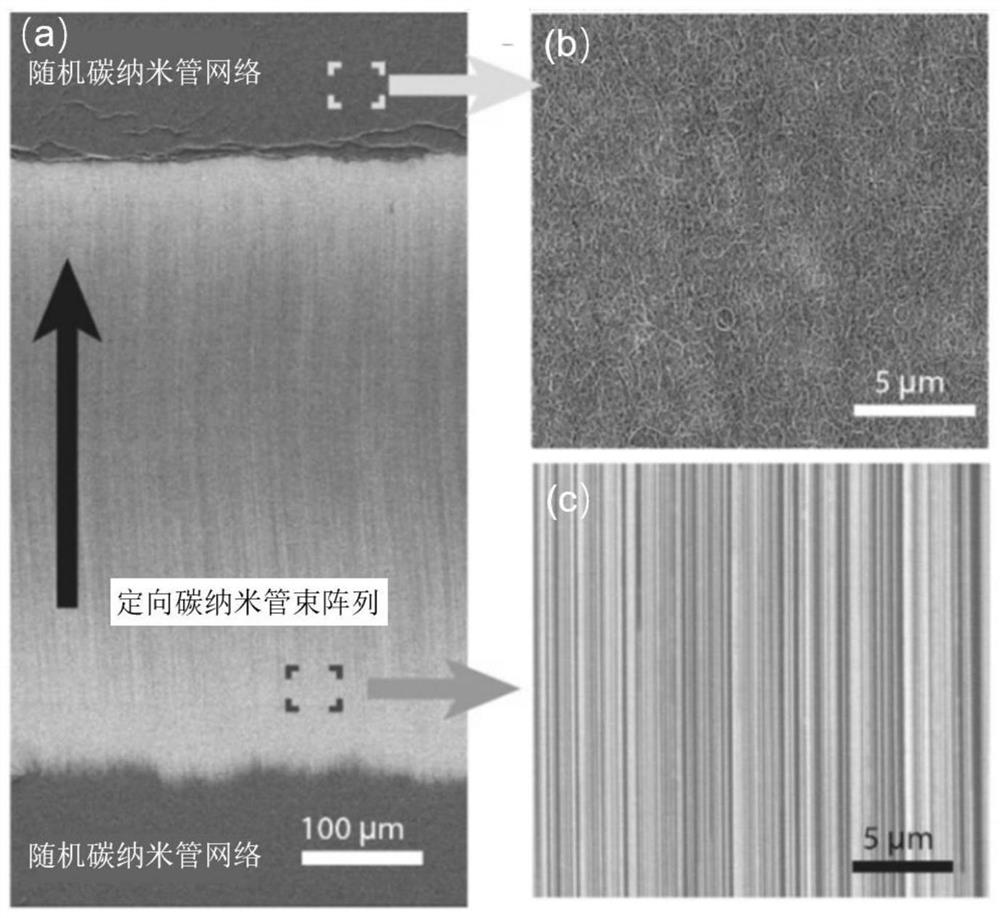

[0049] Example 1 Preparation of Horizontal Super-Oriented Carbon Nanotube Bundle Array

[0050] 1) Synthesis of single-walled carbon nanotubes by floating catalyst chemical vapor deposition

[0051] Under one atmospheric pressure, with ferrocene / xylene / sulfur as the precursor, metal foil (such as nickel, copper) is placed in the downstream of the quartz tube to collect the carbon nanotube network; filled with argon (flow rate is 20sccm) as a load To maintain the system temperature at 1160°C, inject the xylene precursor solution containing ferrocene (0.045g / mL) and sulfur (0.001g / mL) downstream at a rate of 5μL / min, while the carrier gas is replaced by argon / Hydrogen gas mixture (V Ar / V H2 =0.85 / 0.15), the gas flow rate is 1500sccm; the growth time is 20 minutes; the carbon nanotube network film that has been grown is directly peeled off from the metal foil and transferred to SiO 2 / Si substrate.

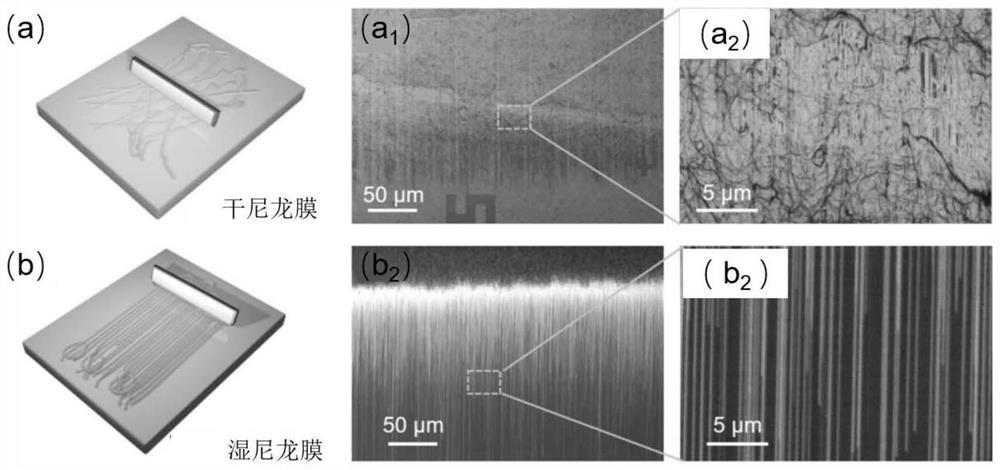

[0052] 2) Preparation of horizontal super-oriented carbon nanotube bundle ...

Embodiment 2

[0055] The preparation process of this example is the same as that of Example 1, only the pressure applied at the same time during the stretching process changes by about 10N / cm 2 .

Embodiment 3

[0057] The preparation process of this example is the same as that of Example 1, only the pressure applied at the same time during the stretching process changes by about 50N / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com