Bead wear-resistant rubber composition and mixing method thereof and tire

A wear-resistant rubber and composition technology, which is applied in the field of new materials for car tire manufacturing, can solve problems such as the influence of unspecified structural rubber properties, unspecified dimensions, chemical structure of aspect ratio, and no wear resistance. Improve the reversion performance, improve the wear performance, reduce the effect of permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

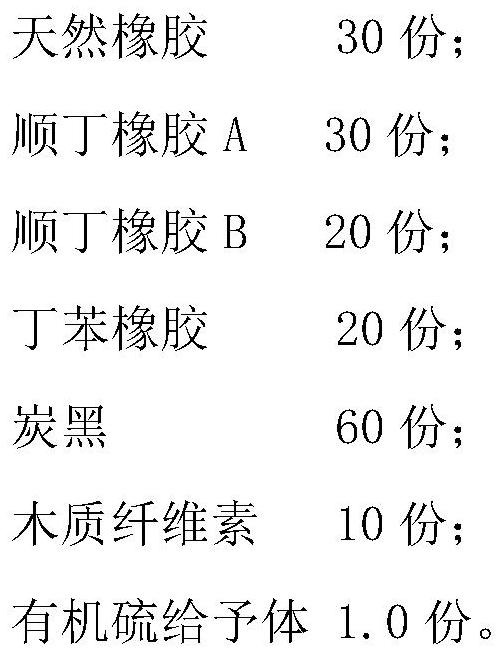

[0027] Below in connection with embodiments of the invention, the technical solutions in the embodiments will be clearly and completely described, obviously, the described embodiments are merely part of embodiments of the present invention rather than all embodiments. Based on the embodiments of the present invention, those of ordinary skill in the art to make all other embodiments without creative effort shall fall within the scope of the invention.

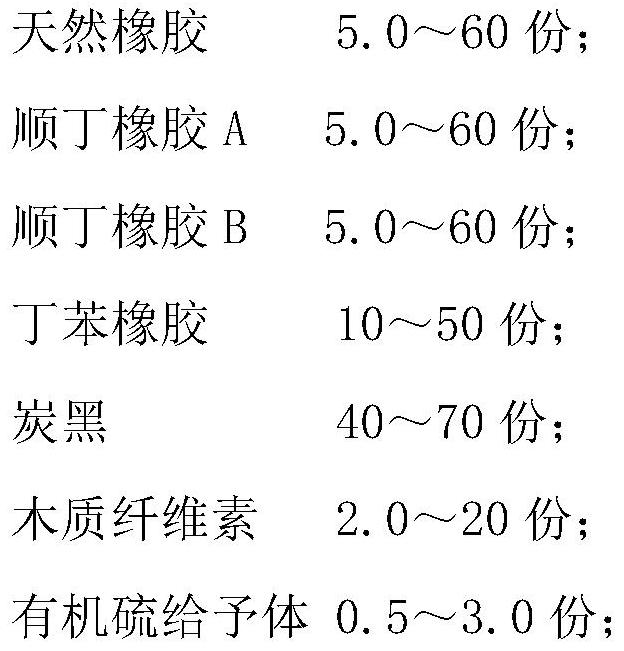

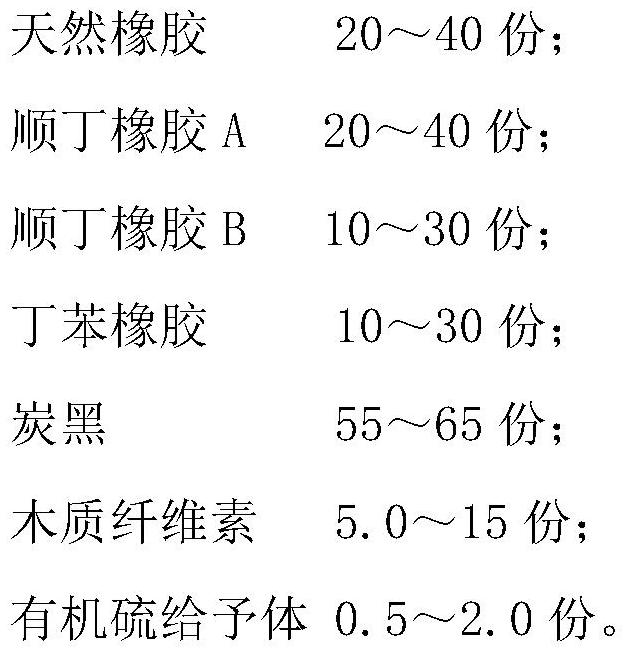

[0028] Comparative Examples 1 to 12 and, as shown in Table 1 and Table 2:

[0029] Note in Table 1 as follows:

[0030] 1 natural rubber STR20, Thai products

[0031] Butadiene rubber 2 A, BR9000, (Cis) cis-butadiene 94.5 mass% of the total weight of the polymer, Daqing Petrochemical Company Product

[0032] 3 butadiene rubber B, BR1250H, vinyl total polymer weight of the 10%, ZEON Chemicals SingaporePte Ltd. Product

[0033] 4 styrene-butadiene rubber, quality SL553, total polymer weight of styrene, 10% vinyl, 39% of the total weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com