Mercaptobenzene functionalized graphene/copper composite heat-conducting coating and preparation method

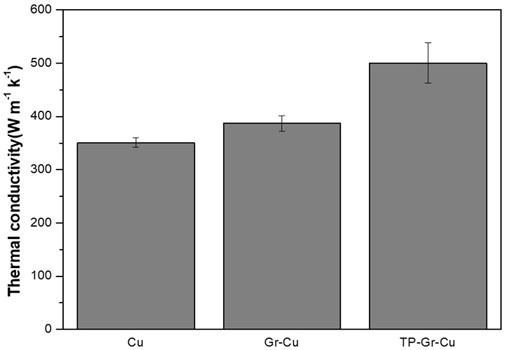

A mercaptobenzene and fossil technology is applied to the mercaptobenzene functionalized graphene/copper composite thermally conductive coating, and in the field of preparation of the composite thermally conductive coating, the effects of reducing interface thermal resistance, remarkable electronic heat transfer efficiency, and simple preparation method are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The method for preparing mercaptobenzene functionalized graphene / copper composite thermally conductive coating comprises the following specific steps:

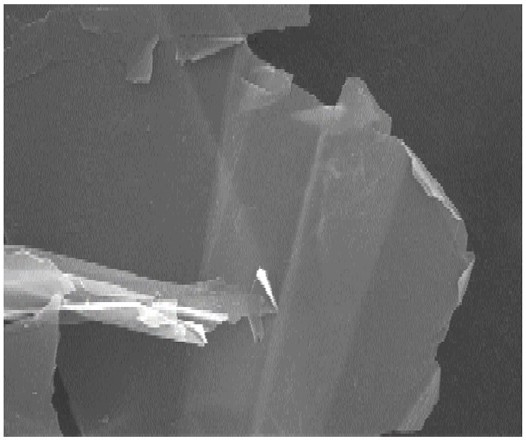

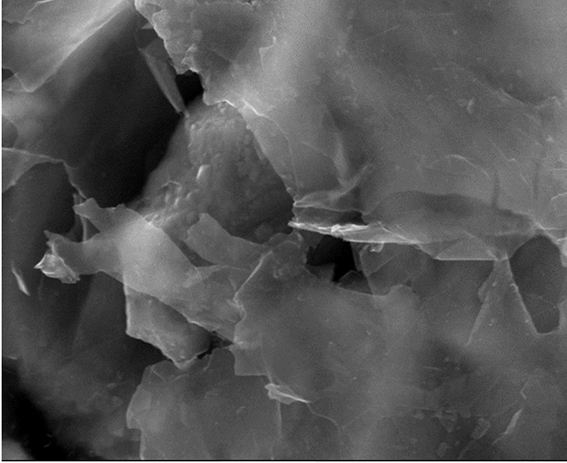

[0021] 1) Preparation of mercaptobenzene-functionalized graphene: 101.4 mg graphene was added to 120 ml o-dichlorobenzene, magnetically stirred for 10 min, and ultrasonically dispersed for 30 min to form a uniformly dispersed suspension; 5.0 g of 4-aminothiophenol was completely Dissolve it in 70 ml of acetonitrile solution, add it to the graphene suspension, and quickly add 11 ml of isoamyl nitrite after passing nitrogen gas for 20 min. The mixture is protected under an inert atmosphere, 60 o C vigorously stirred the reaction for 24 h and cooled to room temperature. Dilute with N,N-dimethylformamide (DMF), separate the suspension with a 0.45 μm organic membrane under vacuum, wash with N,N-dimethylformamide until the filtrate is colorless, and then wash three times with absolute ethanol ,80 o C was dried in vacuum fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com