Preparation method and application of MIL-125 (Ti) catalyst

A MIL-125, catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., to achieve the effects of simple preparation methods, improved activity, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

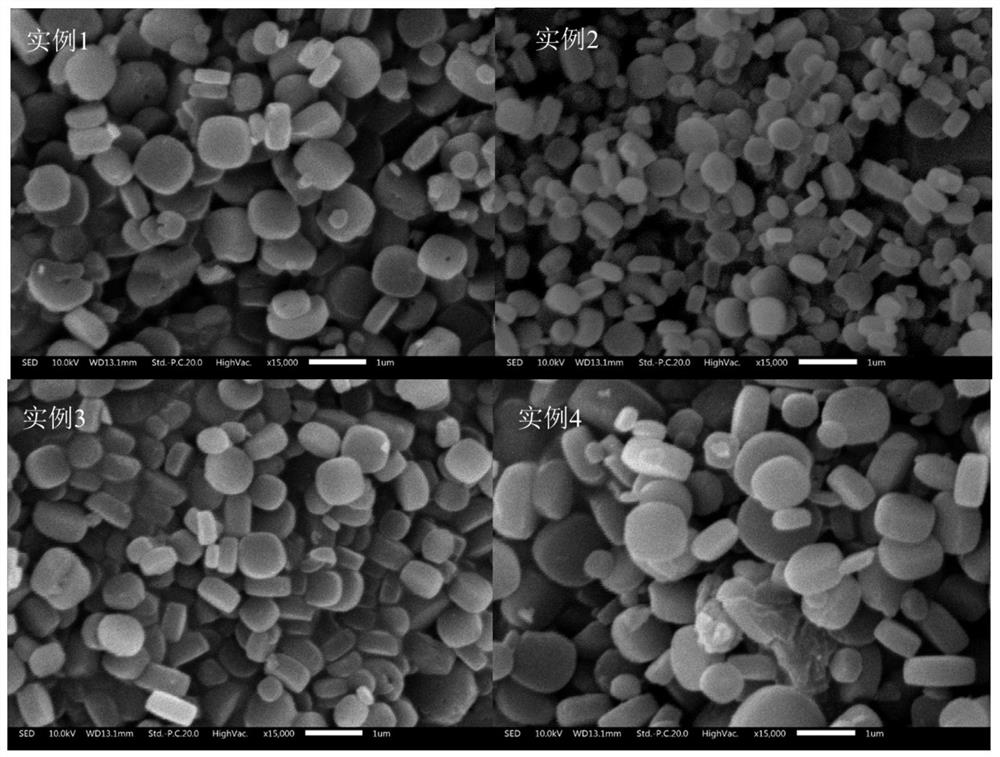

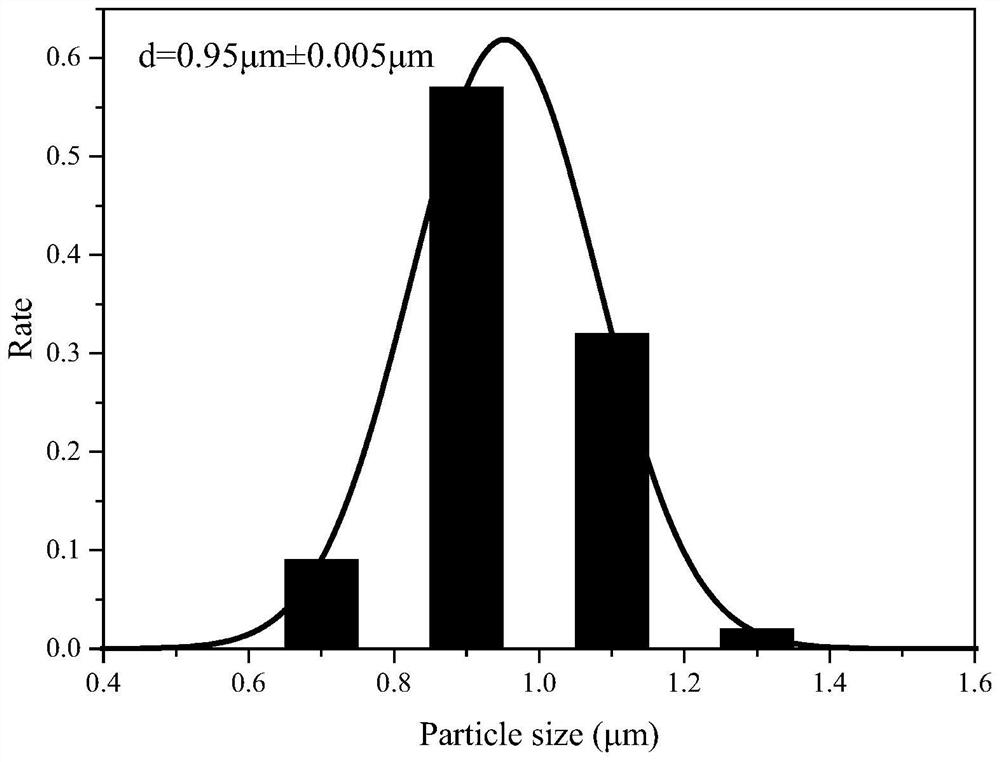

Embodiment 1

[0047] (1) Measure 36mL of N,N-dimethylformamide solution and 4mL of methanol solution in a beaker and mix to obtain a mixed solvent;

[0048] (2) take 2.0g of terephthalic acid and dissolve it in the mixed solvent of step (1), stir to obtain mixed solution;

[0049] (3) Measure 1 mL of tetrabutyl titanate in the mixed solution of step (2), ultrasonicate for 15 minutes, transfer the solution to a polytetrafluoroethylene crystallization kettle, place it in a hydrothermal treatment at 150 ° C for 48 hours, and centrifuge to obtain crystals product;

[0050] (4) The crystalline product obtained in the step (3) was washed three times with N,N-dimethylformamide and methanol, respectively, and was dried under vacuum at 70° C. for 12 hours to obtain the corresponding catalyst.

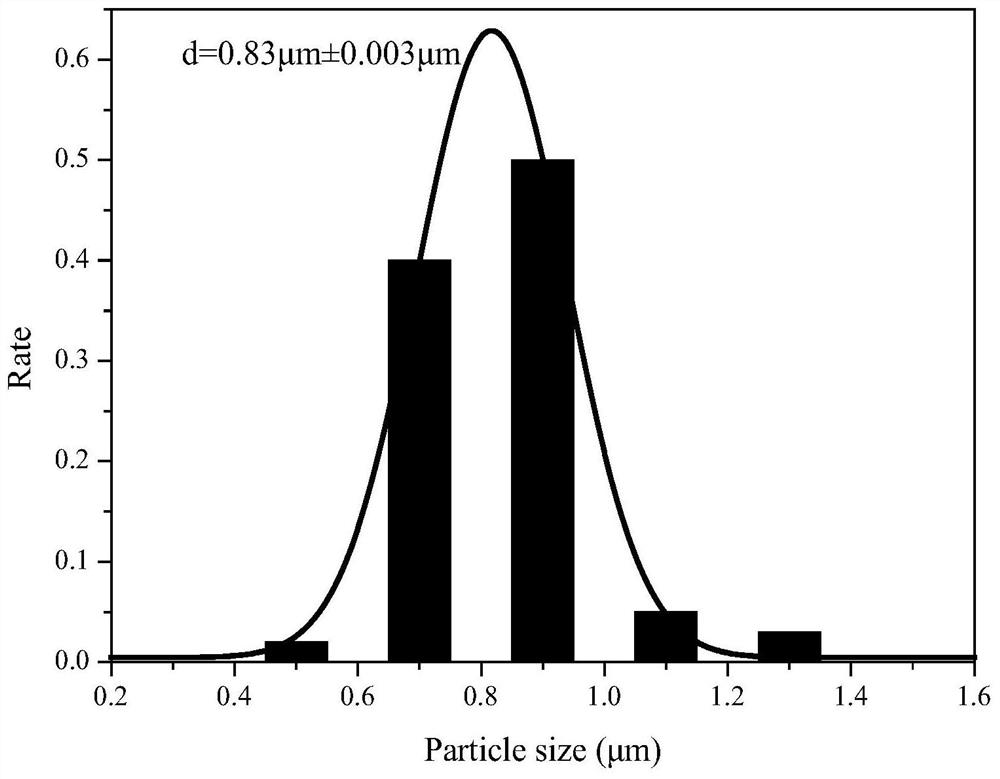

Embodiment 2

[0052] (1) Measure 36mL N,N-dimethylformamide solution and 4mL methanol solution in a beaker and mix to obtain a mixed solvent;

[0053] (2) take 2.0g of terephthalic acid and dissolve it in the mixed solvent of step (1), stir to obtain mixed solution;

[0054] (3) Measure 1 mL of tetrabutyl titanate, weigh 0.1 g of glacial acetic acid in the mixed solution of step (2), ultrasonicate for 15 min, transfer the solution to a polytetrafluoroethylene crystallization kettle, and place it in water at 150° C. Heat treatment for 48h, centrifugation to obtain crystalline product;

[0055] (4) The crystalline product obtained in the step (3) was washed three times with N,N-dimethylformamide and methanol, respectively, and was dried under vacuum at 70° C. for 12 hours to obtain the corresponding catalyst.

Embodiment 3

[0057] (1) Measure 36mL N,N-dimethylformamide solution and 4mL methanol solution in a beaker and mix to obtain a mixed solvent;

[0058] (2) take 2.0g of terephthalic acid and dissolve it in the mixed solvent of step (1), stir to obtain mixed solution;

[0059] (3) Measure 1 mL of tetrabutyl titanate, weigh 0.2 g of glacial acetic acid in the mixed solution of step (2), ultrasonicate for 15 min, transfer the solution to a polytetrafluoroethylene crystallization kettle, and place it in water at 150° C. Heat treatment for 48h, centrifugation to obtain crystalline product;

[0060] (4) The crystalline product obtained in the step (3) was washed three times with N,N-dimethylformamide and methanol, respectively, and was dried under vacuum at 70° C. for 12 hours to obtain the corresponding catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com