A wear-resistant and anti-fouling UV-curable pvc floor coating

An ultraviolet light and floor technology, applied in polyurea/polyurethane coatings, coatings, chemical industries, etc., can solve the problems of reduced anti-fouling effect and easy migration of anti-fouling additives, so as to reduce curing shrinkage and achieve better coating. Antifouling effect, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

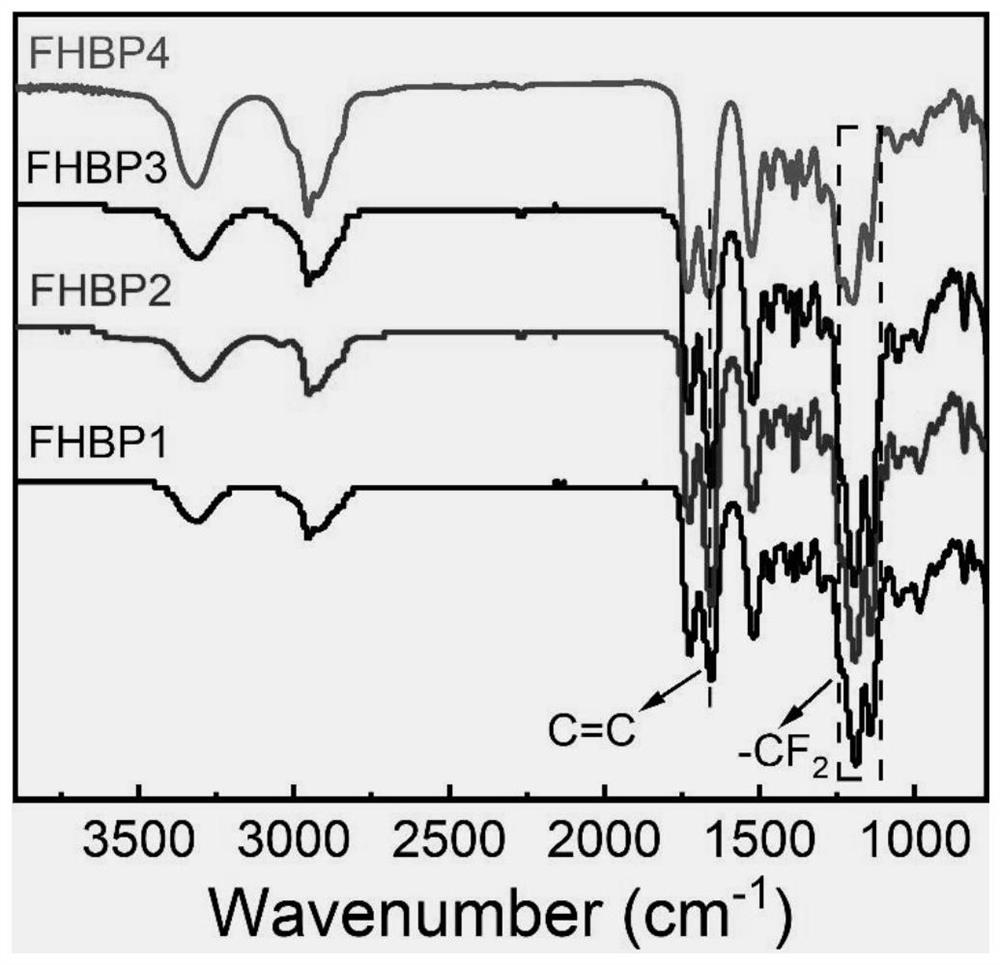

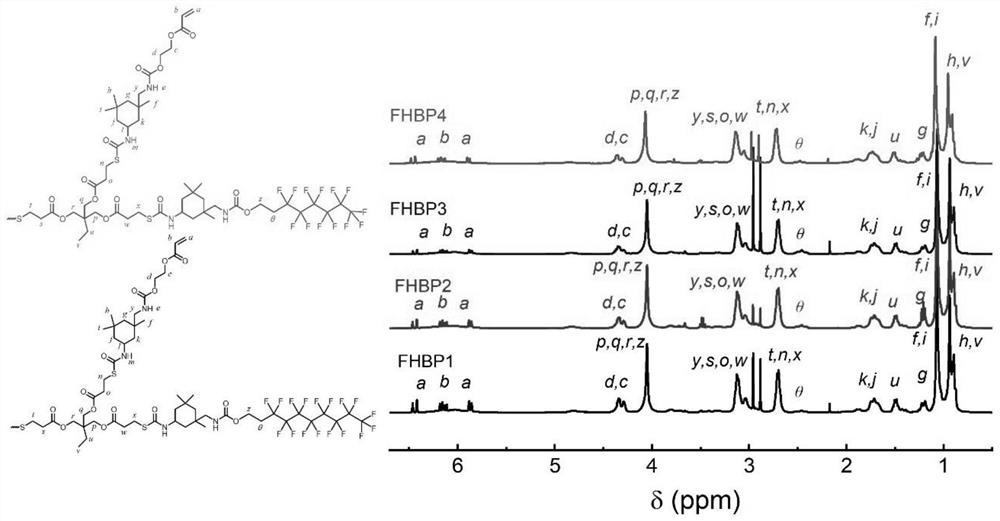

Method used

Image

Examples

Embodiment 1

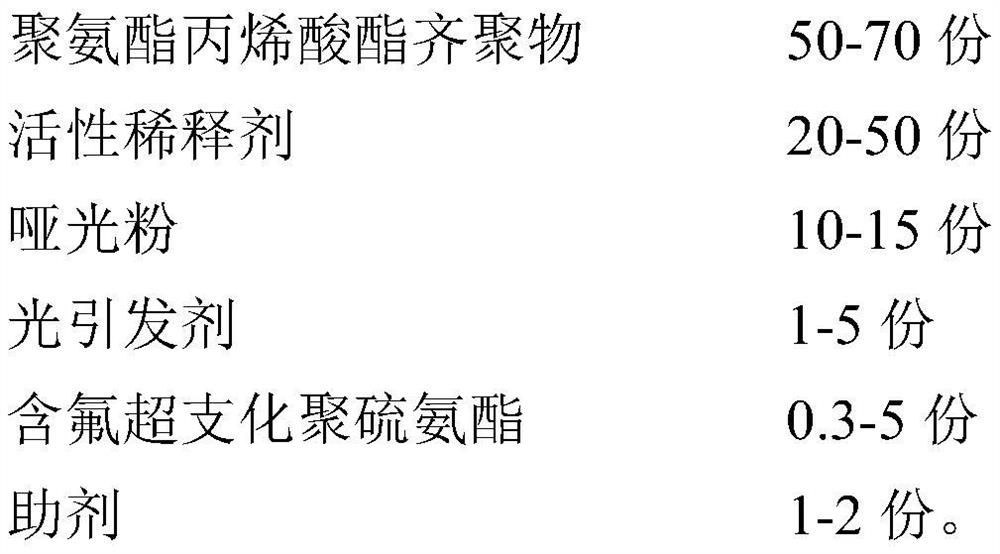

[0034] A UV-cured PVC floor coating, the preparation method is:

[0035] First, use 5 parts of reactive diluent HDDA, 20 parts of reactive diluent PETA, 0.5 part of defoamer BYK-066, 0.5 part of leveling agent BYK-306 and 1 part of wetting and dispersing agent BYK-2009 The high-speed disperser was stirred for 10 minutes at a speed of 2000 r / min to make it dispersed evenly.

[0036] Next, 3 parts of fluorine-containing hyperbranched polythiourethane and 15 parts of matte powder E-1011 were added in batches, and the mixture was stirred at a rotational speed of 3500 r / min for 30 min.

[0037] Finally, add 20 parts of difunctional aliphatic urethane acrylate, 30 parts of hexafunctional aliphatic urethane acrylate, and 5 parts of photoinitiator 1173, and stir evenly at a speed of 2500 r / min to obtain a UV-curable PVC floor coating .

[0038] The preparation method of the fluorine-containing hyperbranched polythiourethane is:

[0039] 3.986 g (10 mmol) trimethylolpropane tris(3-m...

Embodiment 2

[0043] A UV-cured PVC floor coating, the preparation method is:

[0044]First, use 5 parts of reactive diluent HDDA, 20 parts of reactive diluent PETA, 0.5 part of defoamer BYK-066, 0.5 part of leveling agent BYK-306 and 1 part of wetting and dispersing agent BYK-2009 The high-speed disperser was stirred for 10 minutes at a speed of 2000 r / min to make it dispersed evenly.

[0045] Next, 3 parts of fluorine-containing hyperbranched polythiourethane and 15 parts of matte powder E-1011 were added in batches, and the mixture was stirred at a rotational speed of 3500 r / min for 30 min.

[0046] Finally, add 20 parts of difunctional aliphatic urethane acrylate, 30 parts of hexafunctional aliphatic urethane acrylate, and 5 parts of photoinitiator 1173, and stir evenly at a speed of 2500 r / min to obtain a UV-curable PVC floor coating .

[0047] The preparation method of the fluorine-containing hyperbranched polythiourethane is:

[0048] 3.986 g (10 mmol) trimethylolpropane tris(3-me...

Embodiment 3

[0052] A UV-cured PVC floor coating, the preparation method is:

[0053] First, use 5 parts of reactive diluent HDDA, 20 parts of reactive diluent PETA, 0.5 part of defoamer BYK-066, 0.5 part of leveling agent BYK-306 and 1 part of wetting and dispersing agent BYK-2009 The high-speed disperser was stirred for 10 minutes at a speed of 2000 r / min to make it dispersed evenly.

[0054] Next, 3 parts of fluorine-containing hyperbranched polythiourethane and 15 parts of matte powder E-1011 were added in batches, and the mixture was stirred at a rotational speed of 3500 r / min for 30 min.

[0055] Finally, add 20 parts of difunctional aliphatic urethane acrylate, 30 parts of hexafunctional aliphatic urethane acrylate, and 5 parts of photoinitiator 1173, and stir evenly at a speed of 2500 r / min to obtain a UV-curable PVC floor coating .

[0056] The preparation method of the fluorine-containing hyperbranched polythiourethane is:

[0057] 3.986 g (10 mmol) trimethylolpropane tris(3-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com