Preparation method of anti-freezing small-molecular peptide of minced fillet

A technology of small molecule peptides and surimi, which is applied in the field of preparation of surimi antifreeze small molecule peptides, can solve the problems of difficult application in industrial production, poor water solubility of antifreeze proteins, and few whole fish extractions, etc., to achieve improved antifreeze Freezing activity performance, satisfying large-scale production, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

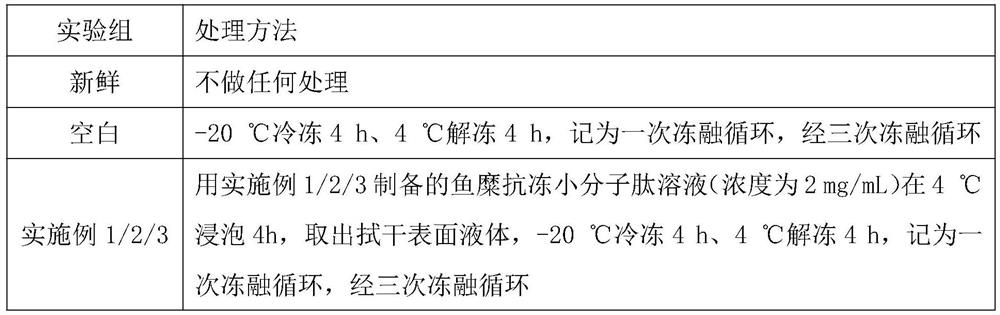

Embodiment 1

[0038] (1) Preparation of water-extracted crude protein from large yellow croaker

[0039] Using large yellow croaker as raw material, the large yellow croaker was removed from its head and viscera, crushed into minced meat, decalcified in 0.25mol / L EDTA decalcification solution for 12 hours, washed with water until neutral, and decalcified minced meat was obtained. Take 550g of decalcified minced meat, add 5500g of water, use a homogenizer at 10000rpm, homogenize for 10min, then stir at 40rpm at 4°C for 6h to extract protein, and centrifuge at 10000G for 30min to obtain a crude protein solution extracted from water .

[0040] (2) Freeze drying

[0041] The water-extracted crude protein solution obtained in step (1) is freeze-dried using a gradient temperature change method, and the time-temperature program of freeze-drying is set as follows, the first section: pre-freeze at -60°C for 3 hours, the second section: freeze at -50°C for 3 hours , the third section: freeze at -40...

Embodiment 2

[0051] (1) Preparation of water-extracted crude protein from large yellow croaker

[0052] Using large yellow croaker as raw material, the large yellow croaker was removed from the head and viscera, crushed into minced meat, decalcified in 0.25mol / L EDTA decalcification solution for 12 hours, washed with water until neutral, and decalcified minced meat was obtained. Take 450g of decalcified minced meat, add 2250g of water, use a homogenizer at 10000rpm, homogenize for 10min, then stir at 40rpm at 4°C for 6h to extract protein, centrifuge at 10000G for 30min, and obtain a crude protein solution extracted from water.

[0053] (2) Freeze drying

[0054] The water-extracted crude protein solution obtained in step (1) is freeze-dried using a gradient temperature change method, and the time-temperature program of freeze-drying is set as follows, the first section: pre-freeze at -65°C for 3h, the second section: freeze at -50°C for 1h , the third section: freeze at -40°C for 1 hour,...

Embodiment 3

[0064] (1) Preparation of water-extracted crude protein from large yellow croaker

[0065] Using large yellow croaker as raw material, the large yellow croaker was removed from the head and viscera, crushed into minced meat, decalcified in 0.25mol / L EDTA decalcification solution for 12 hours, washed with water until neutral, and decalcified minced meat was obtained. Take 800g of decalcified minced meat, add 8000g of water, use a homogenizer at 10000rpm, homogenize for 10min, then stir at 40rpm at 4°C for 6h to extract protein, and centrifuge at 10000G for 30min to obtain a crude protein solution extracted from water.

[0066] (2) Freeze drying

[0067] The water-extracted crude protein solution obtained in step (1) is freeze-dried using a gradient temperature-changing method. The time-temperature program of freeze-drying is set as follows, the first section: -50°C for 5 hours, the second section: -40°C for 3 hours , the third section: freeze at -25°C for 2 hours, the fourth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com