Xanthoceras sorbifolium bunge plant-based protein beverage and preparation method thereof

A plant-based, Wenguan technology, applied in milk replacers, dairy products, food science and other directions, can solve the problems of Wenguan fruit kernels being bitter and difficult to swallow, limiting the application of plant-based beverages, and lack of debittering and astringent technology. The effect of stable solution, good functional activity and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

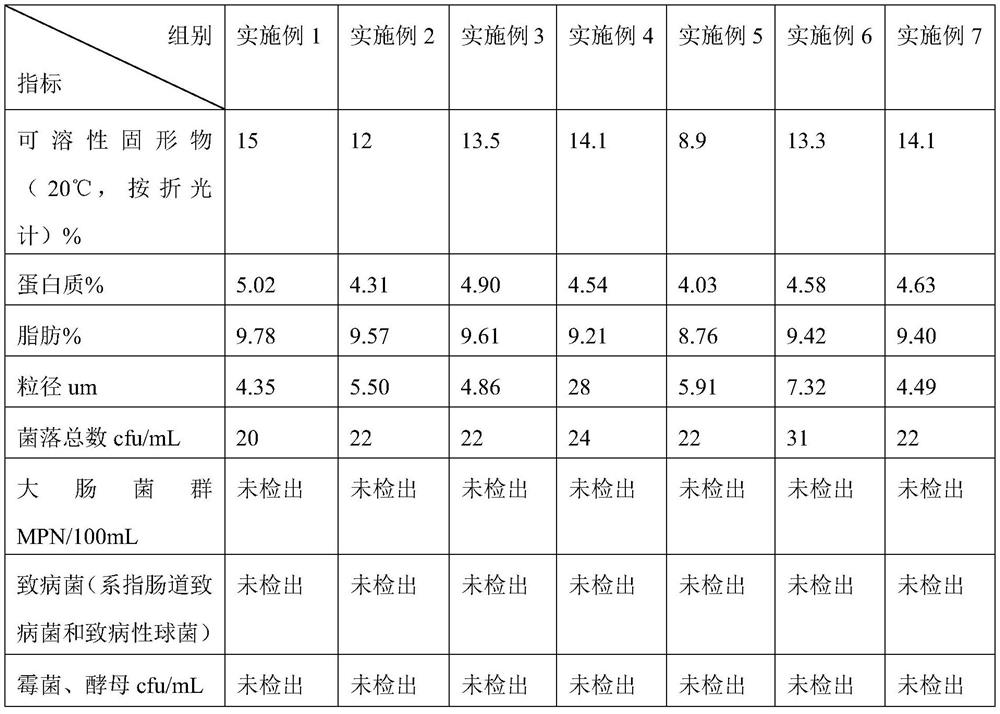

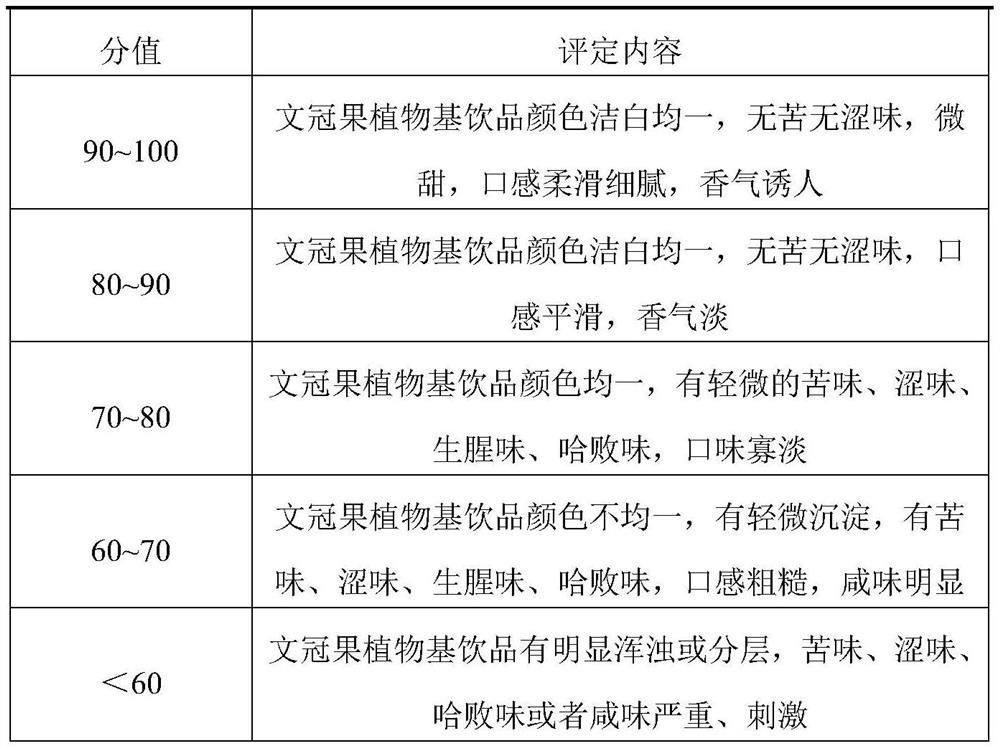

Examples

Embodiment 1

[0030] Sorbifolia plant based drinks prepared:

[0031] Choose full, no rot disease culivated, shelled, the kernel sorbifolia 1: 8 by weight ratio of immersion of demineralized water was added 45 ℃ 2 times, each soaking 4h, draining standby. The sorbifolia seeds after soaking in a 1: 8 ratio by weight of demineralized water is added, under high pressure conditions cooking 1.5MPa 20min, draining after cooking. The sorbifolia seeds after cooking in a 1: ratio of added demineralized water, refining the weight of the pH of the slurry was adjusted to 4.5 with hydrochloric acid 6 added naringinase (100,000 U / g, the total addition amount of the slurry of 0.03% by mass) and acid proteases (200,000 U / g, added in an amount of 1.3% of the total mass of the slurry), stirred for enzyme incubated 1h at 45 ℃, the slurry was off after the hydrolysis enzyme 95 ℃ 5min, filtered to remove slag. After the slurry was digested sorbifolia twice operating conditions of the ultrahigh pressure homogeni...

Embodiment 2

[0033] Sorbifolia plant based drinks prepared:

[0034] Choose full, no rot disease culivated, shelled, the kernel sorbifolia 1: 8 by weight ratio of immersion of demineralized water was added 45 ℃ 2 times, each soaking 4h, draining standby. The sorbifolia seeds after soaking in a 1: 8 ratio by weight of demineralized water is added, under high pressure conditions cooking 1.5MPa 20min, draining after cooking. The sorbifolia seeds after cooking in a 1: ratio of added demineralized water, refining the weight of the pH of the slurry was adjusted to 4.5 with hydrochloric acid 6, addition of an acidic protease (200,000 U / g, the total addition amount of the slurry mass 1.3%), incubated at 45 ℃ stirred IH hydrolysis, the slurry was off after the hydrolysis enzyme 95 ℃ 5min, filtered slag. After the slurry was digested sorbifolia twice operating conditions of the ultrahigh pressure homogenizer 160MPa, sterilized filling, obtained sorbifolia plant-based drinks.

Embodiment 3

[0036] Sorbifolia plant based drinks prepared:

[0037] Choose full, no rot disease culivated, shelled, the kernel sorbifolia 1: 8 by weight ratio of immersion of demineralized water was added 45 ℃ 2 times, each soaking 4h, draining standby. The sorbifolia seeds after soaking in a 1: 8 ratio by weight of demineralized water is added, under high pressure conditions cooking 1.5MPa 20min, draining after cooking. The sorbifolia seeds after cooking in a 1: 6 weight ratio adjustment of demineralized water was added, refining, the pH of the slurry to 4.5 with hydrochloric acid, was added tannase (300U / g, the addition amount of the total mass of the slurry 0.1%) and acid protease (200,000 U / g, added in an amount of 1.3% of the total mass of the slurry), incubated at 45 ℃ stirred IH hydrolysis, the slurry was off after the hydrolysis enzyme 95 ℃ 5min, filtered slag. After the slurry was digested sorbifolia twice operating conditions of the ultrahigh pressure homogenizer 160MPa, sterili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com