Extraction method of coenzyme Q10

An extraction method and coenzyme technology, applied in organic chemistry, quinone separation/purification, etc., can solve problems such as difficult absorption, gap, and poor water solubility, and achieve the effects of easy purification, accelerated concentration rate, and cost-saving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

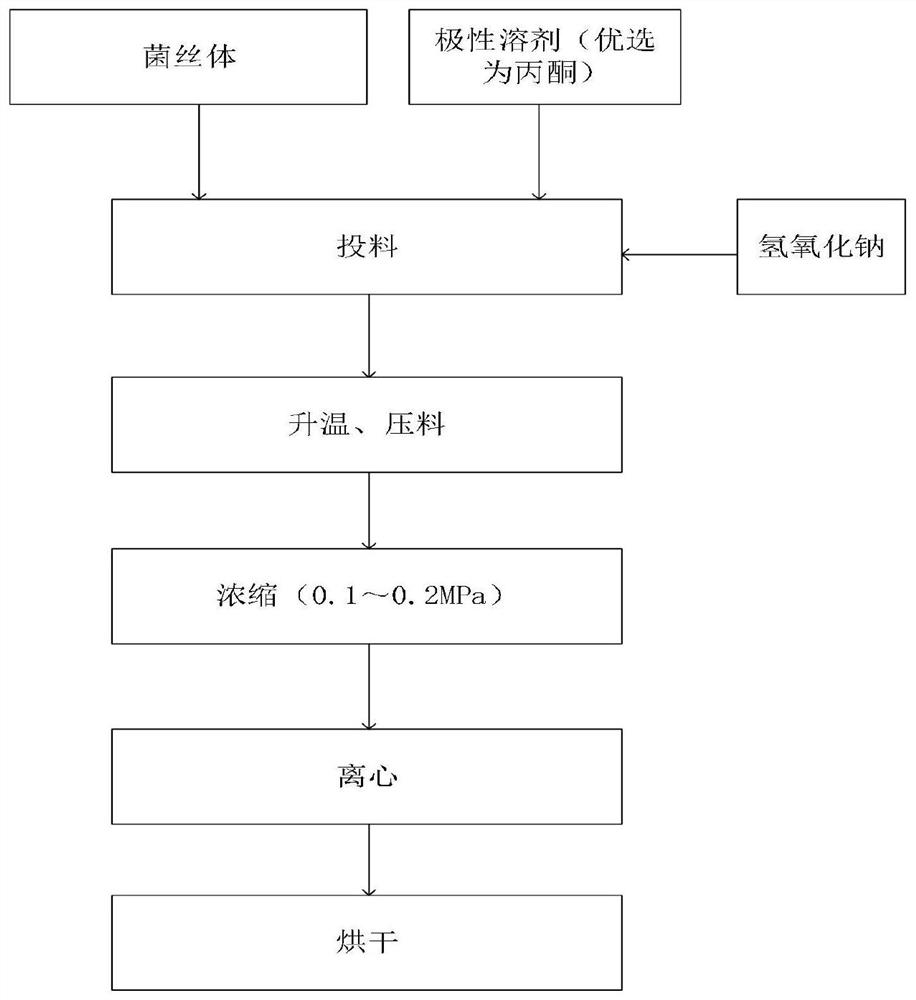

Method used

Image

Examples

Embodiment 1

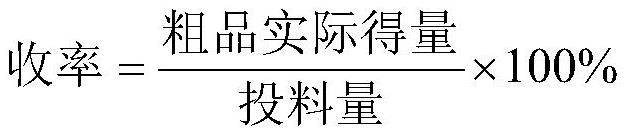

[0059] The present invention proposes a method for extracting coenzyme Q10, which specifically includes the following steps:

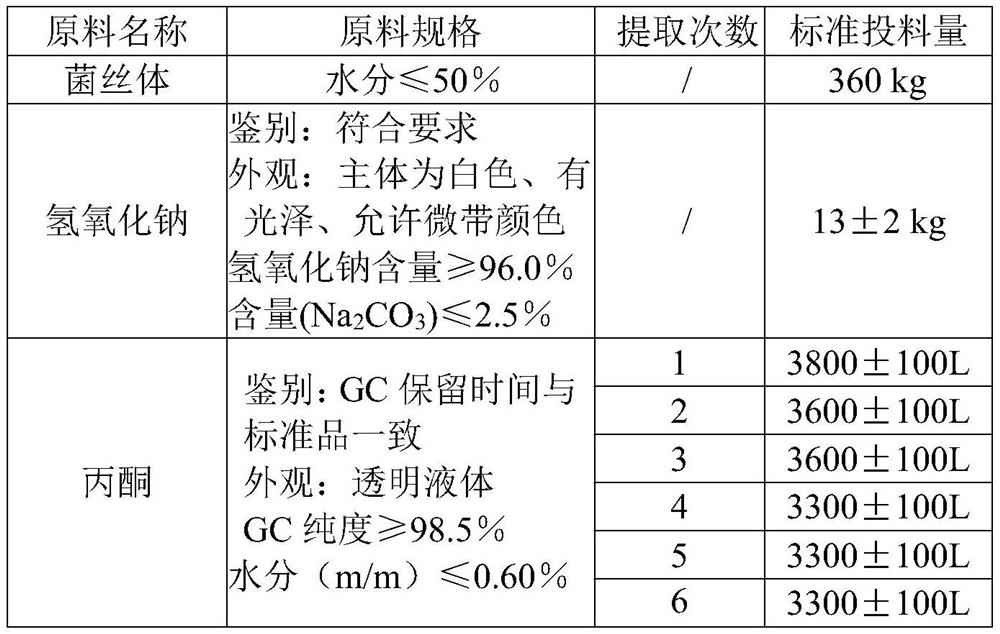

[0060] Feed intake: add 360kg methanemicrobial mycelia, 11kg sodium hydroxide and 3900L acetone into the extraction tank; (this embodiment repeats the extraction 4 times, and the amount of acetone added each time is 3900L, 3600L, 3600L, 3300L respectively)

[0061] Stirring: Stir the mycelia, sodium hydroxide and acetone in the extraction tank, and at the same time turn on the steam to raise the temperature, the steam pressure is 0.1Mpa, and the temperature is raised to about 60°C;

[0062] Pressing: stop stirring when the temperature rises to about 60°C, press the material after 10 minutes of heat preservation, when the pressing pressure reaches 0.05Mpa, stop feeding the interlayer steam, filter the extract and press it into the concentration tank;

[0063] Concentration: Concentrate the extract in the concentration tank, keep the pressure at about 0....

Embodiment 2

[0067] The present invention proposes a method for extracting coenzyme Q10, which specifically includes the following steps:

[0068] Feed intake: 360kg methanemicrobial mycelium, 13kg sodium hydroxide and 3800L acetone are added in the extraction tank; (this embodiment repeats extraction 5 times, and the addition amount of each acetone is respectively 3800L, 3600L, 3500L, 3400L, 3200L )

[0069] Stirring: Stir the mycelia, sodium hydroxide and acetone in the extraction tank, and at the same time turn on the steam to raise the temperature, the steam pressure is 0.15Mpa, and the temperature is raised to about 65°C;

[0070] Pressing: Stop stirring when the temperature rises to about 65°C, and press the material after 12 minutes of heat preservation. When the pressing pressure reaches 0.05Mpa, stop feeding the interlayer steam, filter the extract and press it into the concentration tank;

[0071] Concentration: Concentrate the extract in the concentration tank, keep the pressur...

Embodiment 3

[0075] The present invention proposes a method for extracting coenzyme Q10, which specifically includes the following steps:

[0076] Feeding: 360kg denitrifying bacteria mycelium, 15kg sodium hydroxide and 3800L acetone are added in the extraction tank; (this embodiment repeats the extraction 6 times, and the addition of each acetone is respectively 3800L, 3600L, 3500L, 3400L, 3300L, 32500L)

[0077] Stirring: Stir the methanemicrobial mycelia, sodium hydroxide and acetone in the extraction tank, and at the same time turn on the steam to raise the temperature, the steam pressure is about 0.2Mpa, and the temperature is raised to about 70°C;

[0078] Pressing: stop stirring when the temperature rises to about 70°C, and press the material after 15 minutes of heat preservation. When the pressing pressure reaches 0.05Mpa, stop feeding the interlayer steam, filter the extract and press it into the concentration tank;

[0079] Concentration: Concentrate the extract in the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com