Nano composite material and application thereof in preparation of high-opacity plain decorative base paper

A nano-composite material, chitosan technology, applied in the field of papermaking, can solve the problems of water absorption capacity decline, paper page absorption performance, etc., to achieve the effect of improving smoothness, improving paper opacity, and good concealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

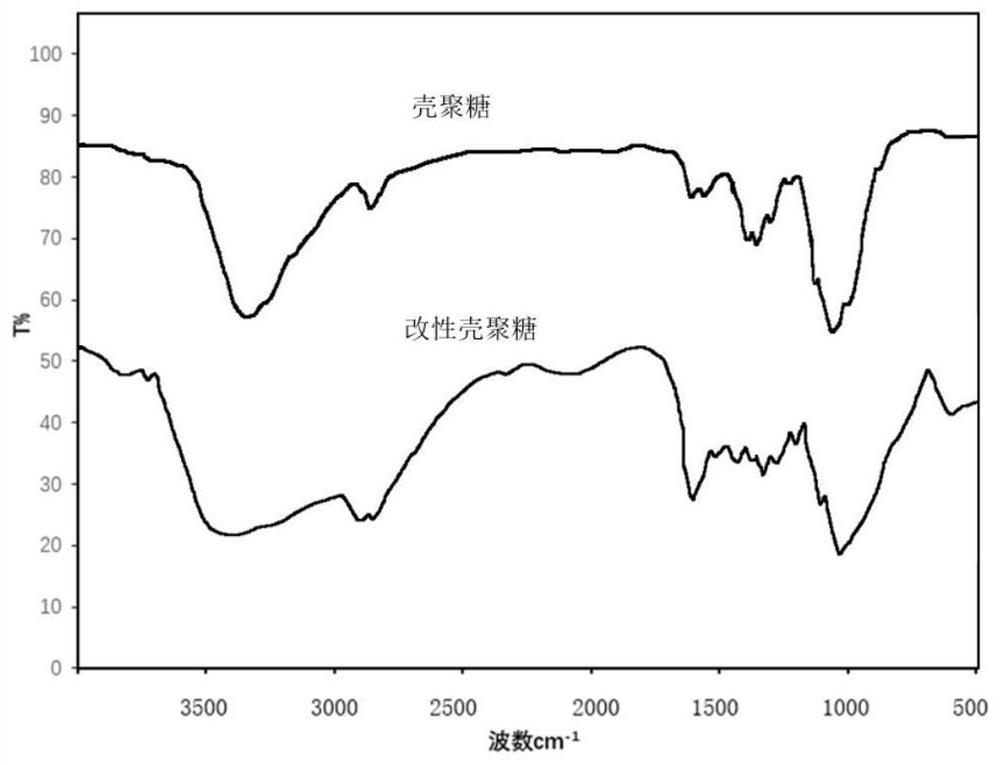

[0042] Preparation of modified chitosan

[0043] Mix 4g chitosan, 35% NaOH and 60g cyclohexanol, stir at 50°C for 4h; slowly add 60% chloroacetyl-L-valine aqueous solution after stirring; Adjust the pH to be neutral; then soak in methanol, wash with absolute ethanol, and dry to obtain the modified chitosan.

Embodiment 2

[0045] Preparation of nanocomposites

[0046] Take chitosan and 1% (v / v) acetic acid solution to prepare a chitosan acetic acid solution with a concentration of 2g / mL, heat to 60°C and stir for 2h; then add 2wt% nano-titanium dioxide and stir for 2h before ultrasonic dispersion 20 minutes is the nano-composite liquid, and the nano-composite liquid is spray-dried into powder under the conditions of the inlet air temperature of 150°C and the outlet air temperature of 60°C to obtain the nano-composite material.

Embodiment 3

[0048] Preparation of nanocomposites

[0049] The difference between this example and Example 2 is that this example uses the modified chitosan prepared in Example 1 to prepare a nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com