Au-loaded ZnO microspheres as well as preparation method and application thereof

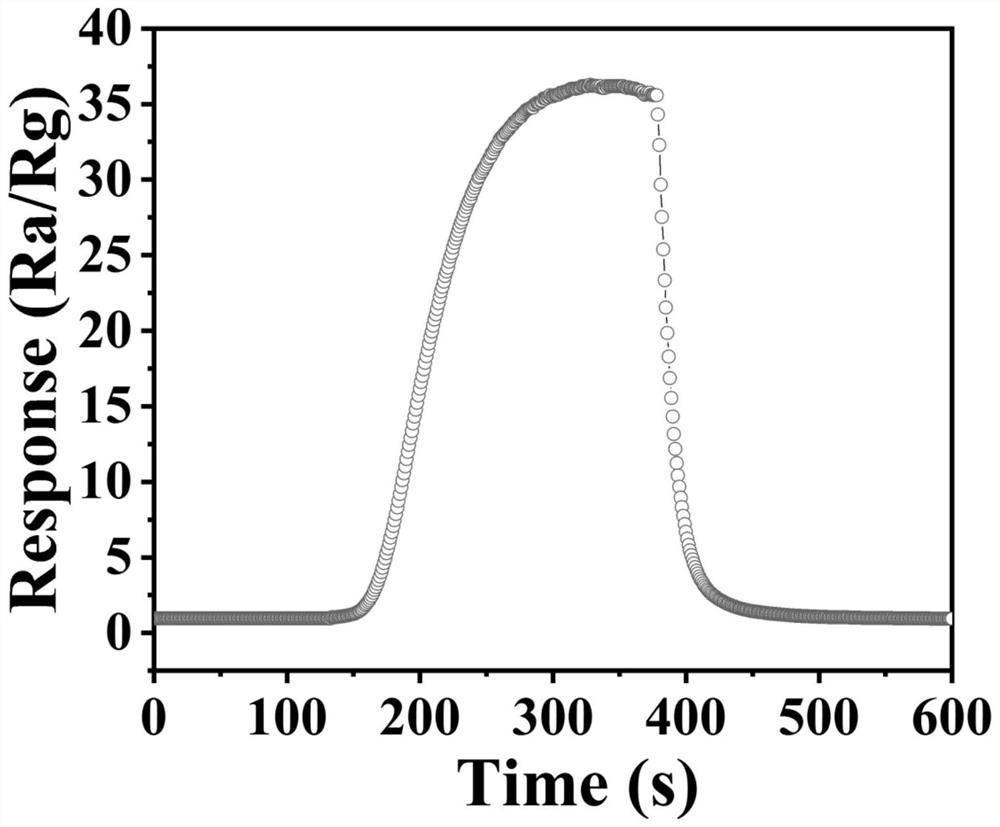

A technology of microspheres and nanoparticles, applied in measuring devices, instruments, and material analysis through electromagnetic means, can solve the problems of low sensitivity and high working temperature of aniline gas sensors, and achieve low working temperature, low preparation cost and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

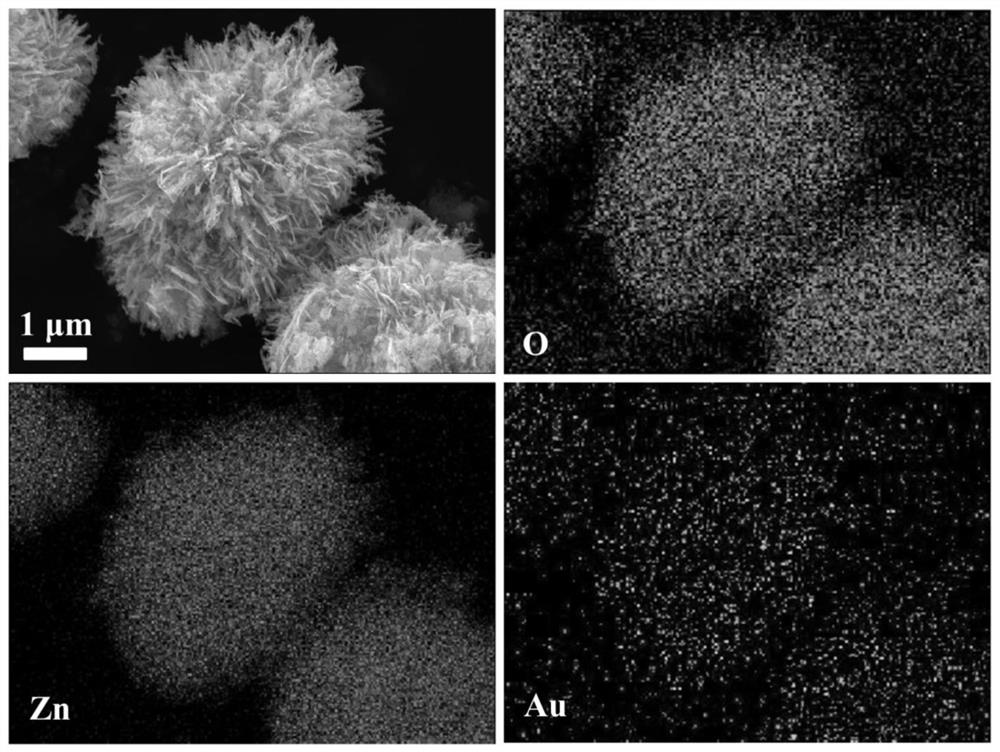

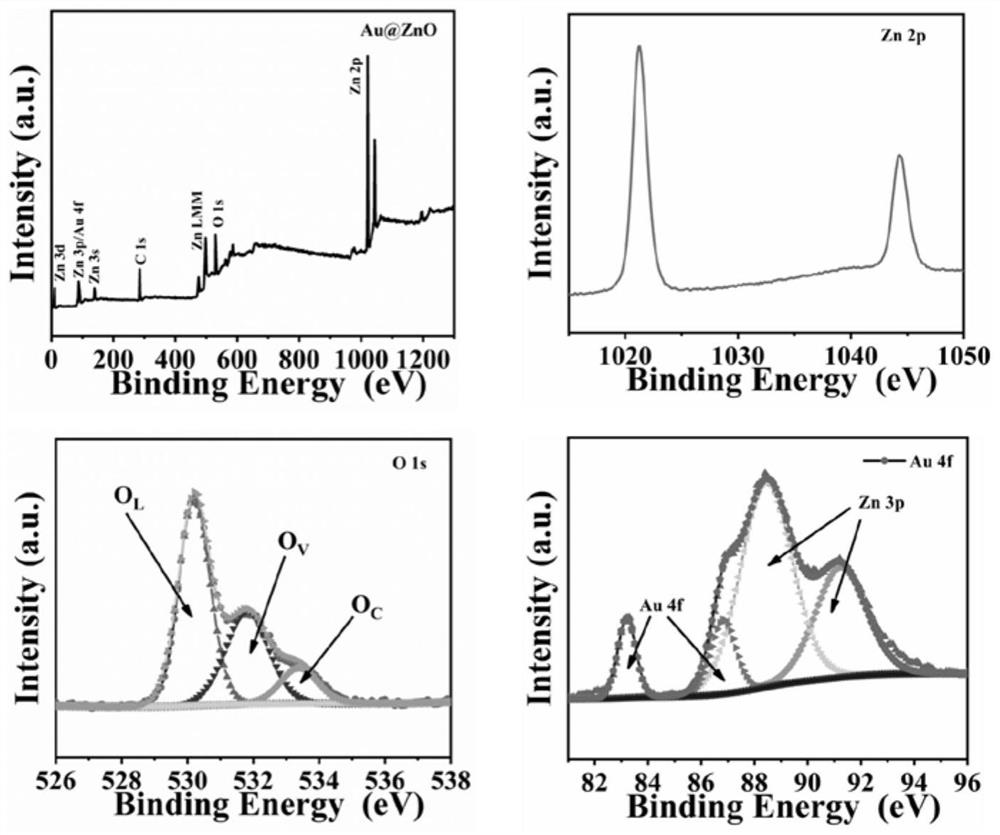

[0026] The preparation method of the Au-loaded ZnO microspheres of this embodiment is as follows:

[0027] (1) Prepare zinc salt solution: dissolve 0.1g CTAB in a mixture of 30 mL ethanol and 15 mL deionized water, add 1 mmol zinc acetate to prepare zinc salt solution;

[0028] (2) Preparation of ZnO microspheres: add 0.5 mmol NaOH to the zinc salt solution in step (1) to obtain a suspension; after hydrothermal reaction at 100°C for 12 hours, the obtained product is washed, dried, and calcined at 300°C for 2 hours to obtain ZnO microspheres ball;

[0029] (3) Preparation of Au-loaded ZnO microspheres: Add 100 mg of ZnO microspheres prepared in step (2) to a solvent of 4 mL of methanol and 20 mL of deionized water and add 133 μL of 1 g / L chloroauric acid solution (wherein the Au content is 0.1 mg), after stirring evenly, photodeposited for 0.5 h to obtain Au-loaded ZnO microspheres.

Embodiment 2

[0031] The preparation method of the Au-loaded ZnO microspheres of this embodiment is as follows:

[0032] (1) Prepare zinc salt solution: dissolve 0.1g AOT in a mixture of 30 mL methanol and 10 mL deionized water, add 1 mmol zinc nitrate to prepare zinc salt solution;

[0033] (2) Preparation of ZnO microspheres: Add 1 mmol urea to the zinc salt solution in step (1) to obtain a suspension; after hydrothermal reaction at 100°C for 12 hours, the obtained product is washed, dried, and calcined at 300°C for 2 hours to obtain ZnO microspheres ball;

[0034] (3) Preparation of Au-supported ZnO microspheres: Add 100 mg of ZnO microspheres prepared in step (2) to a solvent of 4 mL methanol and 20 mL deionized water and add 500 μL of 1 g / L chloroauric acid solution (wherein the Au content is 0.38 mg), after stirring evenly, photodeposited for 1 h to obtain Au-loaded ZnO microspheres.

Embodiment 3

[0036] The preparation method of the Au-loaded ZnO microspheres of this embodiment is as follows:

[0037] (1) Prepare zinc salt solution: Dissolve 0.1g PVP in a mixture of 35 mL ethylene glycol and 5 mL deionized water, add 1 mmol zinc chloride to prepare zinc salt solution;

[0038] (2) Preparation of ZnO microspheres: add 2 mmol ammonia water to the zinc salt solution in step (1) to obtain a suspension; after hydrothermal reaction at 100°C for 12 hours, the obtained product is washed, dried, and calcined at 300°C for 2 hours to obtain ZnO microspheres ball;

[0039] (3) Preparation of Au-loaded ZnO microspheres: Add 100 mg of ZnO microspheres prepared in step (2) to a solvent of 4 mL methanol and 20 mL deionized water and add 800 μL of 1 g / L chloroauric acid solution (where the Au content is 0.6 mg), after stirring evenly, photodeposited for 2 h to obtain Au-loaded ZnO microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com