Battery diaphragm coating material, preparation method thereof, battery diaphragm and battery

A technology for coating materials and battery separators, which can be used in the direction of separators/films/diaphragms/spacers, secondary batteries, battery components, etc., and can solve problems such as low ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

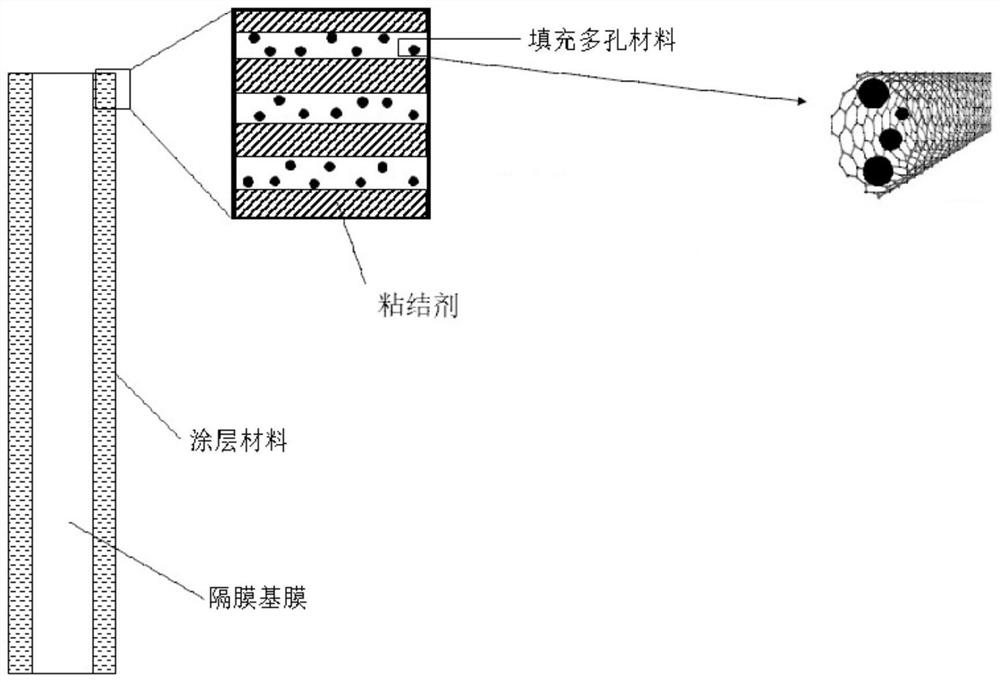

[0033] This embodiment provides a battery separator, which is prepared according to the following steps:

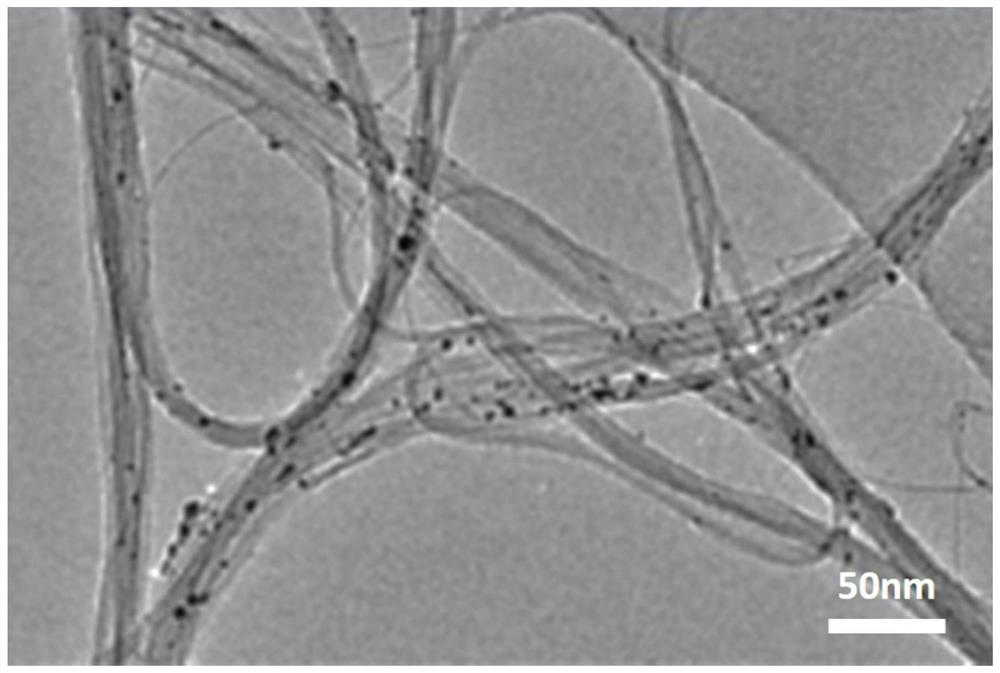

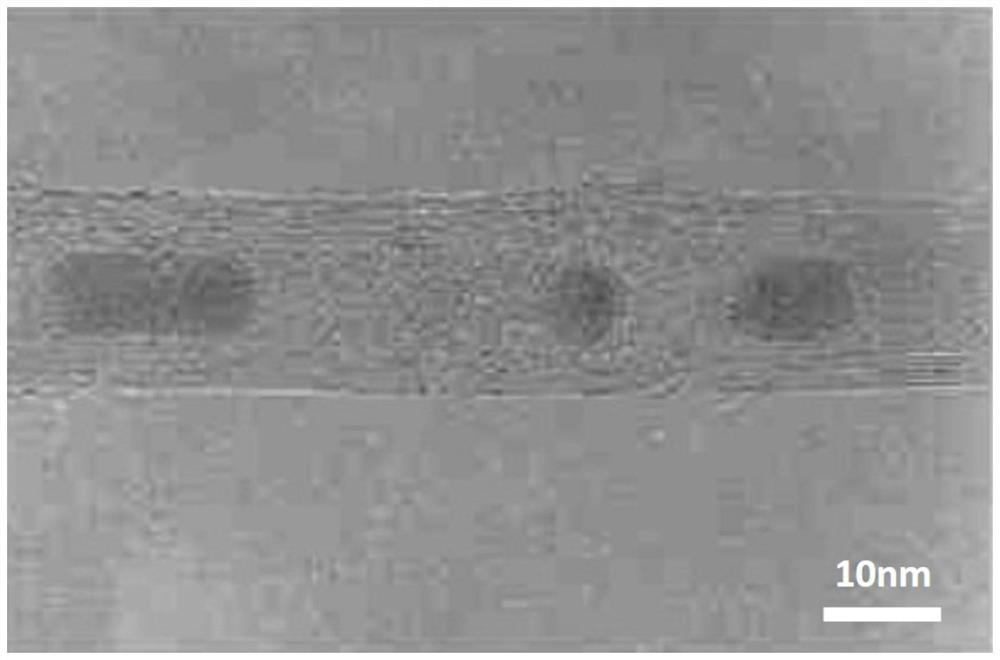

[0034] (1) Take 30 parts by mass of carbon nanotubes and 70 parts by mass of lithium lanthanum zirconium oxygen to form a mixture, wherein the ratio of the particle size of the lithium lanthanum zirconium oxide material to the pore size of the carbon nanotubes is 1:3 (referred to as the particle size The pore diameter ratio is 1:3), add 100 parts by mass of solvent deionized water to the mixture, fully grind to obtain a viscous slurry, then transfer the slurry to a three-necked flask, and add 2000 parts by mass of deionized water again, Connect the condensing water device, heat with an oil bath, and carry out heating and reflux reaction at 125°C with mechanical stirring, and the reaction time is 2h.

[0035] (2) Centrifuge the dispersion after the reaction, and then perform suction filtration. After the suction filtration, vacuum dry in a vacuum oven for 48 hours at a dry...

Embodiment 2-13

[0040] Examples 2-13 respectively provide a battery separator, and the preparation process is the same as that of Example 1, except that it is made according to the formula in Table 1.

[0041] The formula composition of battery diaphragm in the embodiment 1-13 of table 1

[0042]

[0043]

[0044] Wherein, the solvent used in the preparation process of Example 8 is absolute ethanol, and the solvent used in Example 9 is ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com